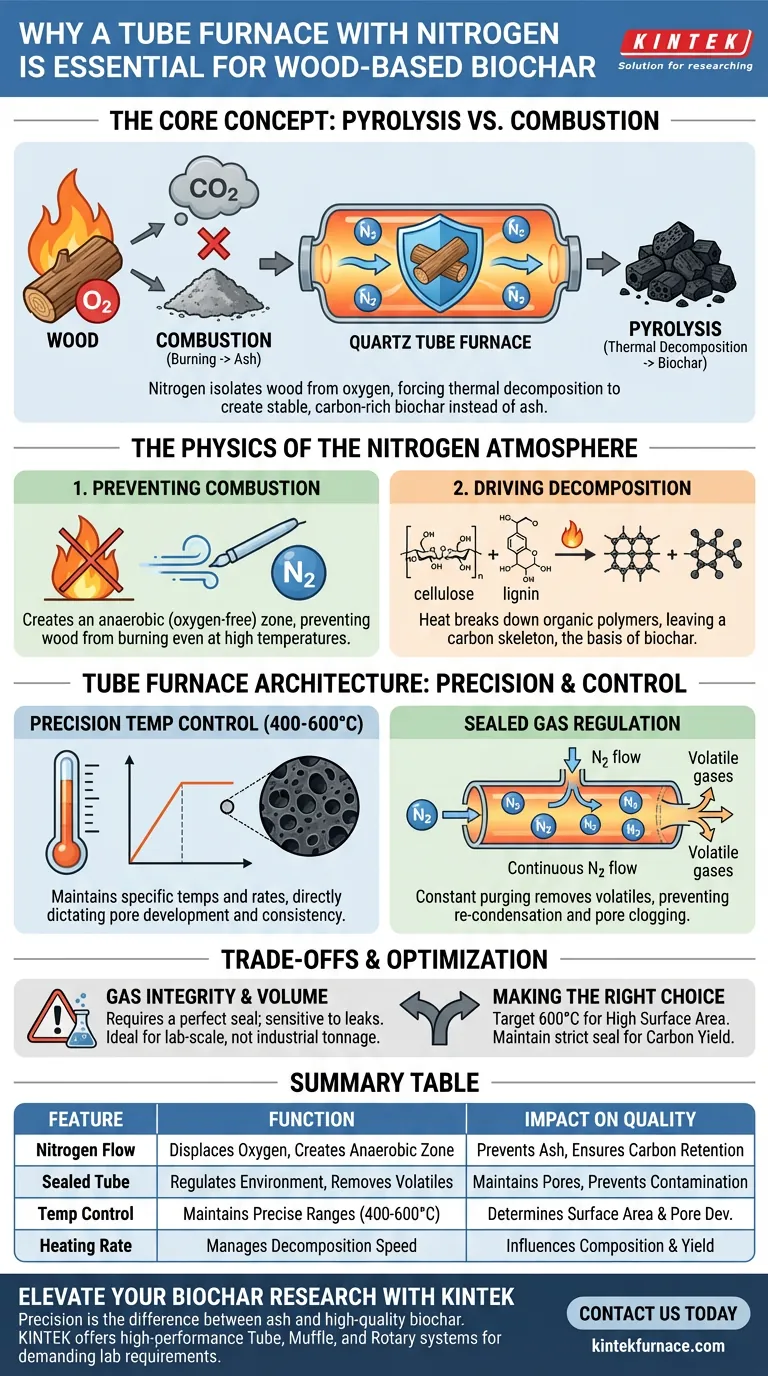

A tube furnace with a nitrogen environment is critical because it isolates the wood from oxygen to prevent combustion. The nitrogen acts as a protective shield, forcing the biomass to undergo pyrolysis—thermal decomposition without fire—rather than simply burning into ash. This specific setup allows you to convert organic wood matter into a stable, carbon-rich material with a defined porous structure.

Core Takeaway The nitrogen flow creates an artificial "reducing environment" that makes pyrolysis possible. Without this inert gas displacing oxygen, high temperatures would incinerate the wood; with it, the furnace precisely engineers the wood's internal structure into high-quality biochar.

The Physics of the Nitrogen Atmosphere

Preventing Oxidative Combustion

In a standard environment, heating wood to high temperatures triggers combustion, reacting with oxygen to produce carbon dioxide and ash.

Nitrogen eliminates this variable. By continuously flowing nitrogen through the tube, you create an anaerobic (oxygen-free) zone. This ensures that the wood does not burn, even when subjected to intense heat.

Driving Thermal Decomposition

Once the threat of burning is removed, the heat serves a different purpose: thermal decomposition.

This process breaks down the complex organic polymers in wood, specifically cellulose and lignin. The nitrogen environment allows these components to degrade chemically, leaving behind a carbon skeleton that forms the basis of biochar.

The Role of the Tube Furnace Architecture

Precision Temperature Control

The tube furnace is not just a heater; it is a precision instrument. It allows you to maintain specific temperatures, typically between 400 and 600 °C, and control heating rates (e.g., 20 °C per minute).

This control is vital because the temperature directly dictates the pore development of the biochar. If the temperature is too low, decomposition is incomplete; if it varies wildly, the pore structure becomes inconsistent.

Sealed Gas Regulation

The "tube" design is specifically engineered for gas flow control. Unlike open ovens, a sealed tube allows for a continuous, regulated stream of high-purity nitrogen.

This constant purging removes volatile gases released during pyrolysis, preventing them from re-condensing on the biochar and clogging its pores.

Understanding the Trade-offs

Sensitivity to Gas Integrity

The effectiveness of this system relies entirely on the seal. Even a microscopic leak in the tube or a fluctuation in nitrogen purity can introduce oxygen.

At these high temperatures, even trace amounts of oxygen can compromise the surface functional groups of the biochar or lead to partial combustion, reducing yield and quality.

Volume Limitations

Tube furnaces are generally batch-processing units ideal for laboratories or small-scale synthesis.

They offer superior control over the elemental composition and structure of the char, but they are volume-constrained. Scaling this level of precision up to industrial tonnage requires significantly more complex and expensive equipment than a standard tube furnace.

Making the Right Choice for Your Goal

To maximize the utility of a nitrogen-equipped tube furnace, you must align your settings with your desired outcome:

- If your primary focus is High Surface Area: Target the higher end of the temperature spectrum (around 600 °C) to maximize the evacuation of volatiles and the development of micropores.

- If your primary focus is Carbon Yield: Maintain a strictly sealed environment with steady nitrogen flow to prevent any oxidative loss of mass.

The tube furnace converts heat from a destructive force into a constructive tool, allowing you to engineer the microscopic architecture of your material.

Summary Table:

| Feature | Function in Biochar Production | Impact on Quality |

|---|---|---|

| Nitrogen Flow | Displaces oxygen to create an anaerobic zone | Prevents ash formation; ensures carbon retention |

| Sealed Tube | Regulates gas environment and removes volatiles | Maintains pore structure; prevents surface contamination |

| Temp Control | Maintains precise ranges (400-600°C) | Determines surface area and pore development |

| Heating Rate | Manages the speed of thermal decomposition | Influences elemental composition and yield |

Elevate Your Biochar Research with KINTEK

Precision is the difference between ash and high-quality biochar. Backed by expert R&D and manufacturing, KINTEK offers high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems designed for the most demanding lab requirements. Our furnaces provide the superior gas regulation and temperature uniformity needed to engineer perfect microscopic architectures.

Ready to optimize your carbonization process? Contact us today to discuss our customizable high-temperature solutions for your unique research needs.

Visual Guide

References

- Meiling Huang, Changlei Xia. Sustainable Supercapacitor Electrode Based on Activated Biochar Derived from Preserved Wood Waste. DOI: 10.3390/f15010177

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What factors should be considered when choosing a vertical tube furnace? Key Selection Criteria for Optimal Performance

- Why is environment control within a high-temperature tube furnace essential for converting silica into SiNQ?

- Why is a tube reduction furnace necessary for sub-stoichiometric uranium dioxide? Precision Chemical Reduction Guide

- How does a vertical tube furnace ensure effective hydrogen reduction reactions? Optimize Rare Earth Tailing Processing

- What is the function of a Quartz Tube Furnace in the dry thermal oxidation of silicon wafers? Enhance Your Oxide Quality

- What are the primary industries that use split tube furnaces? Essential for High-Temp Material Processing

- Why is the integration of an axial rotation mechanism significant in tube furnaces? Enhance Experimental Control

- What role does a high-temperature tube furnace play in biomass carbonization? Unlock Superior Biochar Structures