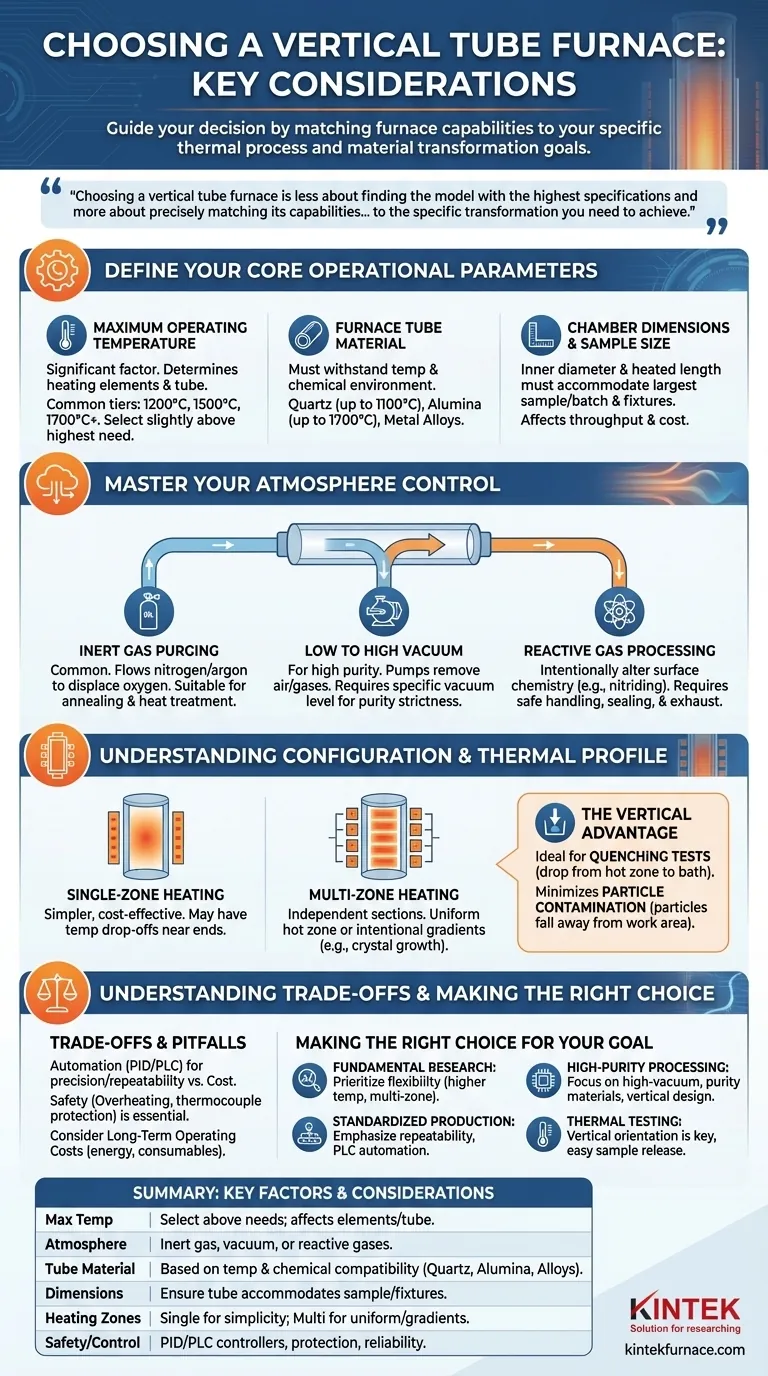

When selecting a vertical tube furnace, your decision must be guided by the specific thermal process you intend to perform. The most critical factors are the maximum temperature required, the type of atmospheric control needed, the physical size of your samples, and the degree of temperature uniformity your process demands. These elements will dictate the furnace's materials, configuration, and ultimate cost.

Choosing a vertical tube furnace is less about finding the model with the highest specifications and more about precisely matching its capabilities—temperature, atmosphere, and configuration—to the specific transformation you need to achieve in your material.

Define Your Core Operational Parameters

Before evaluating any model, you must first define the non-negotiable requirements of your work. These parameters form the foundation of your decision.

Maximum Operating Temperature

The maximum operating temperature is the single most significant factor influencing furnace design and cost. It directly determines the type of heating elements and tube materials that can be used. Common temperature tiers are up to 1200°C, 1500°C, and 1700°C or higher.

Always select a furnace with a maximum temperature slightly above your highest required processing temperature to ensure longevity and avoid running the unit at its absolute limit.

Furnace Tube Material

The process tube must withstand your target temperature and be chemically compatible with your samples and process atmosphere.

- Quartz tubes are common for temperatures up to approximately 1100°C. They offer good thermal shock resistance and visibility.

- Alumina (ceramic) tubes are required for higher temperatures, typically up to 1700°C, offering excellent high-temperature stability and durability.

- Metal alloy tubes are used in specific applications where ceramics may be unsuitable, but they have their own temperature and atmospheric limitations.

Chamber Dimensions and Sample Size

The inner diameter and heated length of the furnace tube must accommodate your largest sample or batch size. Consider not only the sample's dimensions but also any fixtures or boats used to hold it. A larger chamber increases throughput but also raises energy consumption and cost.

Master Your Atmosphere Control

The environment inside the furnace is just as critical as the temperature. The level of atmospheric control you need depends entirely on your material's sensitivity to oxidation and other chemical reactions.

Inert Gas Purging

This is the most common form of atmosphere control. It involves flowing an inert gas like nitrogen or argon through the tube to displace oxygen and prevent oxidation. This is suitable for many annealing and heat treatment processes.

Low to High Vacuum

For applications requiring high purity, you will need a vacuum system. A vacuum furnace uses pumps to remove air and other gases from the chamber before heating or backfilling with a high-purity process gas. The required vacuum level (e.g., high vacuum vs. ultra-high vacuum) depends on the strictness of your purity requirements.

Reactive Gas Processing

Some processes, like nitriding or carburizing, use reactive gases to intentionally alter the surface chemistry of the material. This requires a system designed to safely handle these gases, including appropriate sealing and exhaust management.

Understanding Configuration and Thermal Profile

The physical design of the furnace impacts temperature distribution and its suitability for specific tasks.

Single-Zone vs. Multi-Zone Heating

A single-zone furnace has one set of heating elements and one controller. It is simpler and more cost-effective but may have slight temperature drop-offs near the ends of the tube.

A multi-zone furnace (typically two or three zones) has independently controlled heating sections. This allows for a much longer and more uniform hot zone or for creating intentional temperature gradients along the length of the tube, which is essential for processes like crystal growth.

The Vertical Advantage: Gravity and Purity

The vertical orientation is not just a space-saving feature; it is a critical process tool. It is ideal for quenching tests, where a sample can be dropped from the hot zone into a liquid bath below.

This orientation also minimizes particle contamination, as any shed particles from the furnace or sample fall down and away from the work area, which is crucial in semiconductor and high-purity materials processing.

Understanding the Trade-offs and Pitfalls

A higher price does not always mean a better furnace for your specific needs. Understanding the trade-offs between features and costs is key to making a sound investment.

Automation and Process Control

Most modern furnaces use a PID controller for precise temperature regulation. For more complex, repeatable, or unattended operations, a PLC (Programmable Logic Controller) system offers advanced programming for ramps, dwells, and integration with other equipment like pumps and gas flow controllers.

Safety and Reliability

Do not overlook safety features. Overheating and thermocouple break protection are essential functions that automatically shut down the furnace in an abnormal situation. These are not luxuries; they are critical for protecting your investment, your facility, and your personnel.

Long-Term Operating Costs

Consider the furnace's energy efficiency, the cost of consumable parts like process tubes and seals, and the price of process gases. A cheaper initial purchase may lead to higher operating costs over the furnace's lifetime.

Making the Right Choice for Your Goal

Select a furnace by matching its features to your primary objective.

- If your primary focus is fundamental research with varied materials: Prioritize flexibility, such as a higher temperature range and multi-zone control, to accommodate future, unplanned experiments.

- If your primary focus is high-purity processing (e.g., semiconductors): Focus on a system with high-vacuum capabilities, high-purity tube materials, and a vertical design to minimize particle contamination.

- If your primary focus is standardized production or quality control: Emphasize repeatability and automation through a PLC-based control system to ensure consistent results across every run.

- If your primary focus is thermal testing like quenching or drop tests: The vertical orientation is your most important feature; ensure the furnace allows for easy sample release from the hot zone.

Ultimately, a methodical evaluation of your specific process requirements will lead you to the most effective and efficient furnace for your work.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Maximum Temperature | Select slightly above process needs; affects heating elements and tube materials (e.g., quartz up to 1100°C, alumina up to 1700°C). |

| Atmosphere Control | Options include inert gas purging, vacuum systems, or reactive gases for oxidation prevention or chemical reactions. |

| Tube Material | Choose based on temperature and chemical compatibility: quartz (up to 1100°C), alumina (up to 1700°C), or metal alloys. |

| Chamber Dimensions | Ensure tube inner diameter and heated length accommodate sample size and fixtures for throughput and efficiency. |

| Heating Zones | Single-zone for simplicity, multi-zone for uniform hot zones or temperature gradients in processes like crystal growth. |

| Safety and Control | Features like PID or PLC controllers, overheating protection, and reliability for safe, automated operations. |

Ready to find the perfect vertical tube furnace for your lab? KINTEK specializes in high-temperature furnace solutions, including Vertical Tube Furnaces, designed with deep customization to meet your unique experimental needs. Leveraging our exceptional R&D and in-house manufacturing, we ensure precise temperature control, reliable atmosphere management, and enhanced safety for applications in research, semiconductor processing, and thermal testing. Contact us today to discuss how our advanced furnaces can optimize your processes and deliver consistent results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision