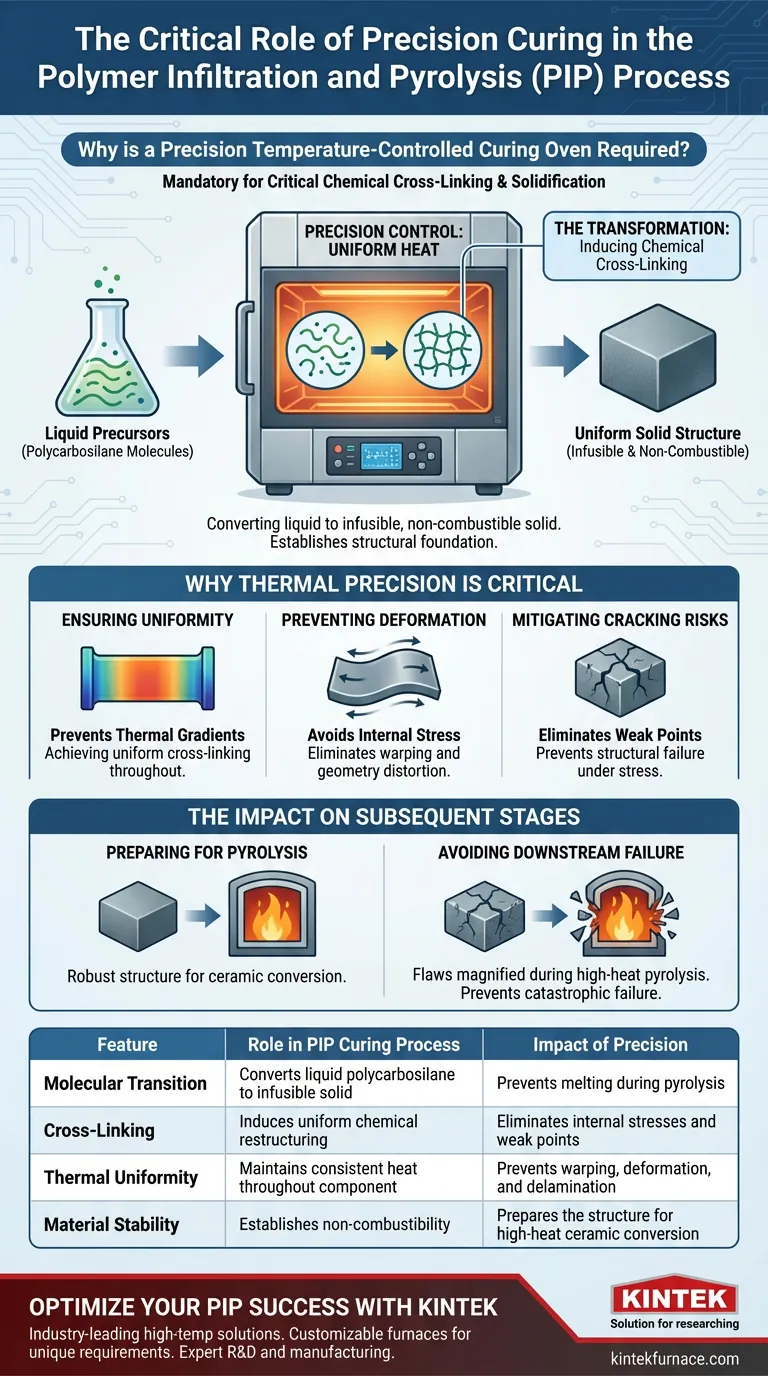

A precision temperature-controlled curing oven is mandatory because it drives the critical chemical cross-linking reactions required to transform liquid precursors into a solid state. This equipment creates a specific thermal environment that converts polycarbosilane molecules from a liquid into an infusible, non-combustible solid, establishing the structural foundation for the material.

Core Takeaway: The primary objective of precision curing is to achieve a uniform degree of cross-linking throughout the material. Without strict thermal control, uneven heating creates internal stresses that inevitably lead to cracking or deformation during the subsequent high-temperature pyrolysis stage.

The Transformation from Liquid to Solid

Inducing Chemical Cross-Linking

The fundamental role of the curing oven is to initiate and sustain a chemical reaction among polycarbosilane molecules. This process is not merely drying; it is a molecular restructuring.

Creating an Infusible State

Through this thermal treatment, the precursor transitions from a manageable liquid into a solid that is infusible. This means the material will no longer melt or flow, even when subjected to intense heat later in the process.

Establishing Non-Combustibility

Simultaneously, the curing process alters the chemical properties to render the solid non-combustible. This stability is a prerequisite for the extreme environments the material will face during pyrolysis.

Why Thermal Precision is Critical

Ensuring Uniformity

The "precision" aspect of the equipment is vital to ensure a uniform degree of cross-linking throughout the entire component. If temperature gradients exist within the oven, different sections of the part will cure at different rates.

Preventing Structural Deformation

Uneven curing results in internal physical stress. If the heating is not precise, the material is prone to deformation, warping the geometry of the final part before the process is even complete.

Mitigating Cracking Risks

Perhaps the most significant risk of poor temperature control is cracking. Variations in the curing level create weak points that will fracture under stress, compromising the integrity of the composite.

The Impact on Subsequent Stages

Preparing for Pyrolysis

The curing stage is effectively a preparation for high-temperature pyrolysis. The solid structure formed here must be robust enough to survive the conversion to ceramic.

Avoiding Downstream Failure

If the cross-linking is not uniform, the flaws will be magnified during pyrolysis. Defects introduced by uneven heating in the curing oven often result in catastrophic failure when the temperature is ramped up in the next processing step.

Understanding the Risks of Imprecision

The Danger of Thermal Gradients

Using standard heating equipment without precision controls often leads to thermal gradients. Even minor fluctuations can result in a part where the surface is cured but the core remains reactive, leading to delamination.

The Cost of "Good Enough"

Compromising on thermal precision is a common pitfall. While less precise ovens are cheaper, they result in inconsistent material properties that render the final PIP product unusable for high-performance applications.

Making the Right Choice for Your Process

Precision in the curing phase is the single biggest determinant of your material's final structural yield.

- If your primary focus is material integrity: Ensure your oven is calibrated to eliminate thermal gradients, guaranteeing a uniform cross-link density across complex geometries.

- If your primary focus is process yield: Prioritize temperature control to prevent the cracking and deformation that are the leading causes of part rejection during pyrolysis.

The success of the entire PIP process relies on the uniformity of the initial cross-linked structure established in this specific thermal environment.

Summary Table:

| Feature | Role in PIP Curing Process | Impact of Precision |

|---|---|---|

| Molecular Transition | Converts liquid polycarbosilane to infusible solid | Prevents melting during pyrolysis |

| Cross-Linking | Induces uniform chemical restructuring | Eliminates internal stresses and weak points |

| Thermal Uniformity | Maintains consistent heat throughout component | Prevents warping, deformation, and delamination |

| Material Stability | Establishes non-combustibility | Prepares the structure for high-heat ceramic conversion |

Optimize Your PIP Success with KINTEK

Don't let thermal gradients compromise your material yields. KINTEK provides industry-leading high-temperature solutions specifically engineered for the rigorous demands of advanced material processing.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, CVD systems, and other lab high-temp furnaces, all customizable for your unique PIP requirements. Whether you need absolute thermal uniformity for delicate cross-linking or robust systems for high-temperature pyrolysis, our specialized equipment ensures your materials achieve peak structural integrity.

Ready to elevate your lab's precision? Contact us today to discuss your custom furnace needs!

Visual Guide

References

- Surface Processing and Characterization of Stoichiometry-Varied BaZrS<sub>3</sub> Thin Films. DOI: 10.1021/acsaem.5c01766

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1200℃ Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- What are batch catalytic debinding ovens used for? Speed Up MIM/CIM with Low-Temp Debinding

- What are the benefits of using advanced technology in heat treatment furnaces? Achieve Superior Material Quality and Efficiency

- What environmental factors can be controlled in a vacuum chamber? Master Pressure, Temperature, Humidity, and Radiation

- Why is a high-pressure reactor with a PTFE lining required for V-NbOPO4@rGO? Ensure Purity in Acidic Synthesis

- How do magnesium impurities influence lithium extraction? Accelerate Production with Heterogeneous Nucleation

- Why is it necessary to preheat casting molds to 300°C? Expert Thermal Control for Recycled Aluminum Alloy Production

- What role does an oscillating furnace play in the synthesis of quaternary Ge-Se-Tl-Sb glass alloys? Ensure Homogeneity

- What is the role of a 5% N2 + 95% H2 mixture in plasma nitriding? Enhance Fatigue Strength and Eliminate White Layers