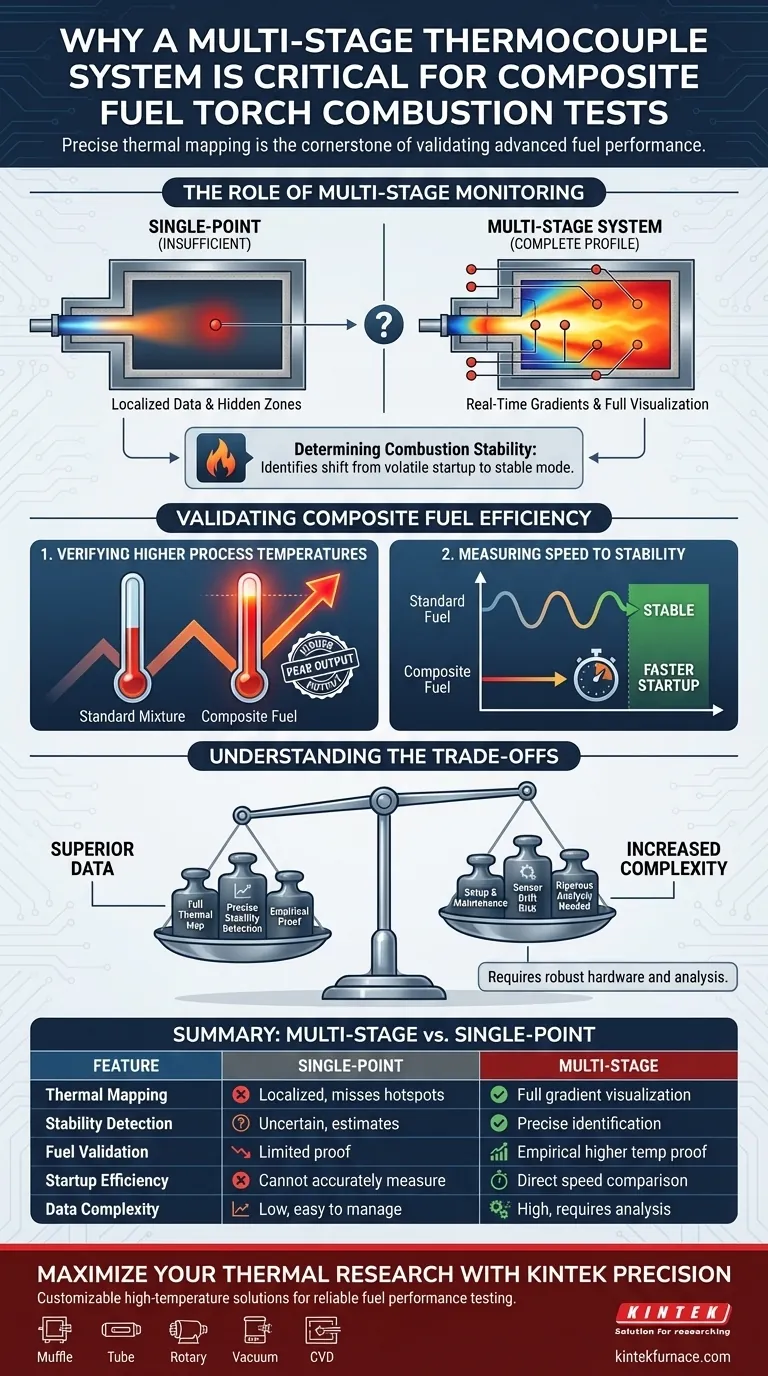

Precise thermal mapping is the cornerstone of validating advanced fuel performance. A multi-stage thermocouple measurement system is necessary to monitor temperature gradients across specific zones of the burner and furnace in real-time. This granular data is the only reliable way to confirm when combustion has stabilized and to empirically prove that composite fuels outperform standard mixtures.

The system provides the critical data points required to verify that composite fuels not only produce higher process temperatures but also achieve stable combustion states significantly faster than ordinary fuel blends.

The Role of Multi-Stage Monitoring

Mapping Real-Time Temperature Gradients

Single-point measurement is often insufficient for complex combustion tests. By deploying thermocouples at various stages of the burner and characteristic positions within the furnace, engineers can visualize the entire thermal profile.

This multi-point approach reveals exactly how heat is distributed throughout the system. It ensures that the temperature readings reflect the actual process conditions rather than localized hotspots or cold zones.

Determining Combustion Stability

Combustion is a dynamic process that fluctuates before settling. The multi-stage system acts as a critical indicator for the state of the burn.

It allows operators to identify precisely when the system shifts from a volatile startup phase to a stable mode. Without this data, it is difficult to know when the test conditions are consistent enough for valid data collection.

Validating Composite Fuel Efficiency

Verifying Higher Process Temperatures

The primary justification for using composite fuels is often their potential to generate more intense heat. This measurement system provides the empirical proof needed to validate this capability.

By comparing the thermal gradients against baselines, the system confirms whether the composite fuel truly produces higher process temperatures than ordinary fuel mixtures.

Measuring Speed to Stability

Efficiency is not just about maximum heat; it is about how quickly that heat is applied. A key performance metric is the time required to reach stability.

The multi-stage data allows for a direct comparison of startup times. It verifies if the composite fuel allows the system to reach a stable combustion mode faster than traditional alternatives, directly impacting operational efficiency.

Understanding the Trade-offs

Increased System Complexity

While a multi-stage system provides superior data, it introduces setup and maintenance complexity. Managing multiple thermocouples increases the risk of sensor drift or failure, which can distort the perceived temperature gradient.

Data Interpretation Demands

Monitoring real-time gradients produces a high volume of data compared to simple temperature checks. It requires rigorous analysis to distinguish between transient thermal fluctuations and genuine changes in the combustion mode.

Applying This to Your Testing Protocol

To get the most out of your combustion analysis, align your data review with your specific engineering goals:

- If your primary focus is operational efficiency: Analyze the time-stamped data to measure exactly how much faster the composite fuel reaches a stable mode compared to your baseline.

- If your primary focus is thermal output: Concentrate on the peak temperature readings at the furnace’s characteristic positions to validate the energy density of the new mixture.

Comprehensive thermal profiling turns combustion testing from a simple observation into a rigorous, quantitative validation of fuel performance.

Summary Table:

| Feature | Single-Point Measurement | Multi-Stage Thermocouple System |

|---|---|---|

| Thermal Mapping | Localized data only; misses hotspots | Full gradient visualization across all zones |

| Stability Detection | Uncertain; relies on estimates | Precise identification of combustion stabilization |

| Fuel Validation | Limited proof of heat distribution | Empirical proof of higher process temperatures |

| Startup Efficiency | Cannot accurately measure time-to-stability | Direct comparison of startup speed and efficiency |

| Data Complexity | Low; easy to manage | High; requires rigorous real-time analysis |

Maximize Your Thermal Research with KINTEK Precision

Precise combustion analysis requires hardware as advanced as your research. At KINTEK, we understand that validating composite fuels depends on reliable, high-performance thermal environments.

Backed by expert R&D and world-class manufacturing, we provide a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other specialized lab high-temperature furnaces. Every system is fully customizable to accommodate your specific multi-stage thermocouple configurations and unique testing requirements.

Ready to elevate your lab's data accuracy? Contact us today to discuss how our customizable high-temperature solutions can optimize your fuel performance testing.

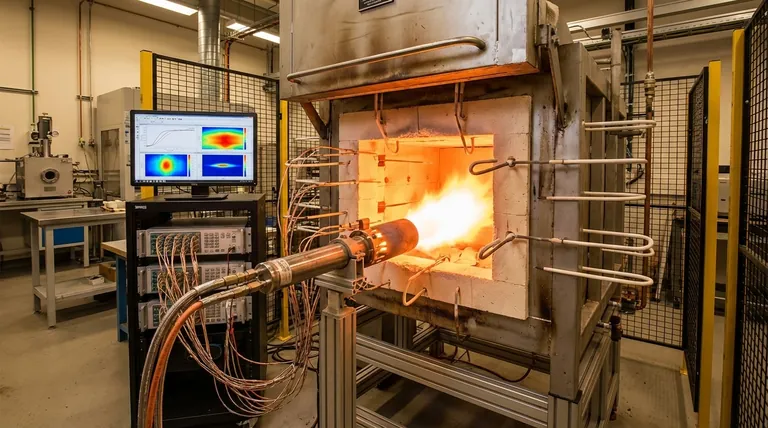

Visual Guide

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Heat Treat Sintering and Brazing Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What advantages does choosing the right ceramic heating element supplier offer? Secure a Strategic Partner for Peak Performance

- What are the common configurations of molybdenum heating elements? Choose the Right Type for Your Furnace

- What is the maximum operating temperature for Silicon Carbide heating elements? Unlock High-Temp Efficiency Up to 1600°C

- What are the benefits of resistance heating elements? Achieve High Efficiency and Precision in Heating

- What are some common types of MoSi2 heating elements and accessories? Discover Shapes, Grades, and Benefits

- What types of industrial applications are MoSi2 heating elements best suited for? Maximize High-Temp Stability

- What are the key properties of 99.7% high-purity alumina ceramic tubes? Discover Their Role in High-Temperature Applications

- Is resistance the only factor in electrical heating? Uncover Key Design Principles for Optimal Performance