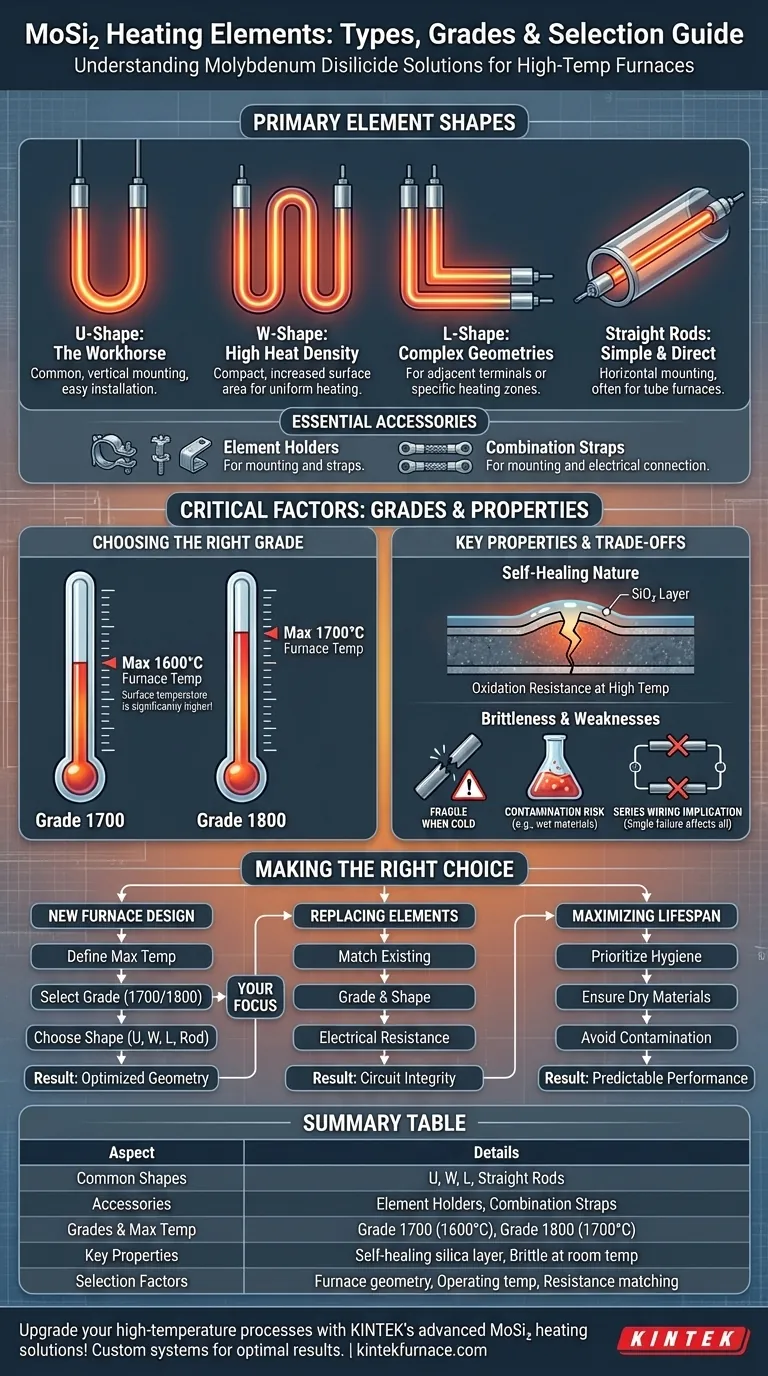

At their core, Molybdenum Disilicide (MoSi₂) heating elements are primarily produced in four common shapes: U-shape, W-shape, L-shape, and straight rods. These core shapes are supported by essential accessories like specialized element holders for mounting and combination straps for electrical connections. The specific shape and grade are chosen to match the furnace's geometry and required operating temperature.

The variety of MoSi₂ element shapes is not for novelty; it is a direct response to the engineering challenge of delivering uniform, high-temperature heat within the specific physical constraints of a furnace. Understanding the purpose of each shape is key to designing and maintaining an efficient high-temperature system.

Understanding the Primary Element Shapes

The shape of a MoSi₂ element is dictated by the furnace's design, including how the elements will be mounted (vertically or horizontally) and how heat must be distributed within the chamber.

The U-Shape: The Industry Workhorse

The U-shape is arguably the most common configuration. Its simple design allows it to be easily suspended vertically from the top of a furnace, with both electrical connections (the "cold zones") exiting through the roof. This simplifies installation and replacement.

The W-Shape: Maximizing Heat Density

A W-shape element is essentially a double U-shape. This design significantly increases the surface area of the heating section within a compact physical footprint, allowing for higher power density and more uniform heating in certain furnace designs.

The L-Shape: Navigating

Complex Geometries

L-shaped elements are used when furnace design requires terminals on adjacent surfaces (e.g., the roof and a side wall). They are also bent to create specific heating zones or to accommodate internal furnace structures.

Straight Rods: Simple and Direct

Straight rod elements are typically mounted horizontally, passing completely through the furnace chamber. They are simple to install and are often used in smaller tube furnaces or where horizontal heating is preferred.

Critical Factors: Grade and Material Properties

Beyond shape, the material's grade and inherent properties are what make MoSi₂ suitable for extreme temperature applications.

Choosing the Right Grade (1700 vs. 1800)

MoSi₂ elements are commonly available in two primary grades, distinguished by their maximum recommended operating temperature:

- Grade 1700: Designed for a maximum furnace temperature of 1600°C.

- Grade 1800: Designed for a maximum furnace temperature of 1700°C.

It is critical to note that the element's surface temperature will be significantly higher than the furnace's internal atmosphere. Selecting the correct grade is essential for element longevity.

The Self-Healing Nature of MoSi₂

The primary advantage of MoSi₂ is its exceptional resistance to oxidation. At high temperatures in an oxygen-rich atmosphere, the element's surface forms a protective, glass-like layer of silica (SiO₂). If this layer is scratched or damaged, the underlying material re-oxidizes, effectively "healing" the protective coating.

Understanding the Trade-offs and Weaknesses

While powerful, MoSi₂ elements are not without their operational vulnerabilities. Acknowledging these is crucial for reliable performance.

High Susceptibility to Contamination

This is the most significant weakness of MoSi₂ elements. Certain chemical compounds, particularly those introduced by improperly dried materials (like painted or colored zirconia), can aggressively attack the protective silica layer and cause rapid element failure. Meticulous furnace hygiene is non-negotiable.

Brittleness at Room Temperature

Like many ceramic-based materials, MoSi₂ elements are hard but very brittle when cold. They must be handled with extreme care during shipping, installation, and any maintenance performed while the furnace is at room temperature to avoid fracture.

Series Wiring Implications

Elements are typically wired in a series circuit. While this simplifies wiring, it means the failure of a single element can disable an entire heating bank. It also underscores the importance of using new elements that are resistance-matched with any existing elements in the same circuit to ensure balanced loading.

Making the Right Choice for Your Application

Selecting the correct components requires balancing the needs of the furnace design with an understanding of the material's properties.

- If your primary focus is a new furnace design: Define your maximum operating temperature first to select the correct element grade, then choose the shape (U, W, L) that best fits your chamber geometry and heat distribution goals.

- If your primary focus is replacing existing elements: Ensure the new elements perfectly match the grade, shape, and electrical resistance of the ones being replaced to maintain circuit integrity and predictable performance.

- If your primary focus is maximizing element lifespan: Prioritize meticulous furnace operation, especially ensuring all materials placed inside are completely dry to prevent chemical contamination and premature failure.

By understanding these factors, you can select and operate MoSi₂ elements not just as components, but as a predictable and reliable high-temperature heating system.

Summary Table:

| Aspect | Details |

|---|---|

| Common Shapes | U-shape, W-shape, L-shape, Straight rods |

| Accessories | Element holders, Combination straps |

| Grades | Grade 1700 (max 1600°C), Grade 1800 (max 1700°C) |

| Key Properties | Self-healing silica layer, Brittle at room temperature |

| Selection Factors | Furnace geometry, Operating temperature, Resistance matching |

Upgrade your high-temperature processes with KINTEK's advanced MoSi2 heating solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable high-temperature furnace systems, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for optimal performance and longevity. Contact us today to discuss how our tailored solutions can enhance your efficiency and results!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance