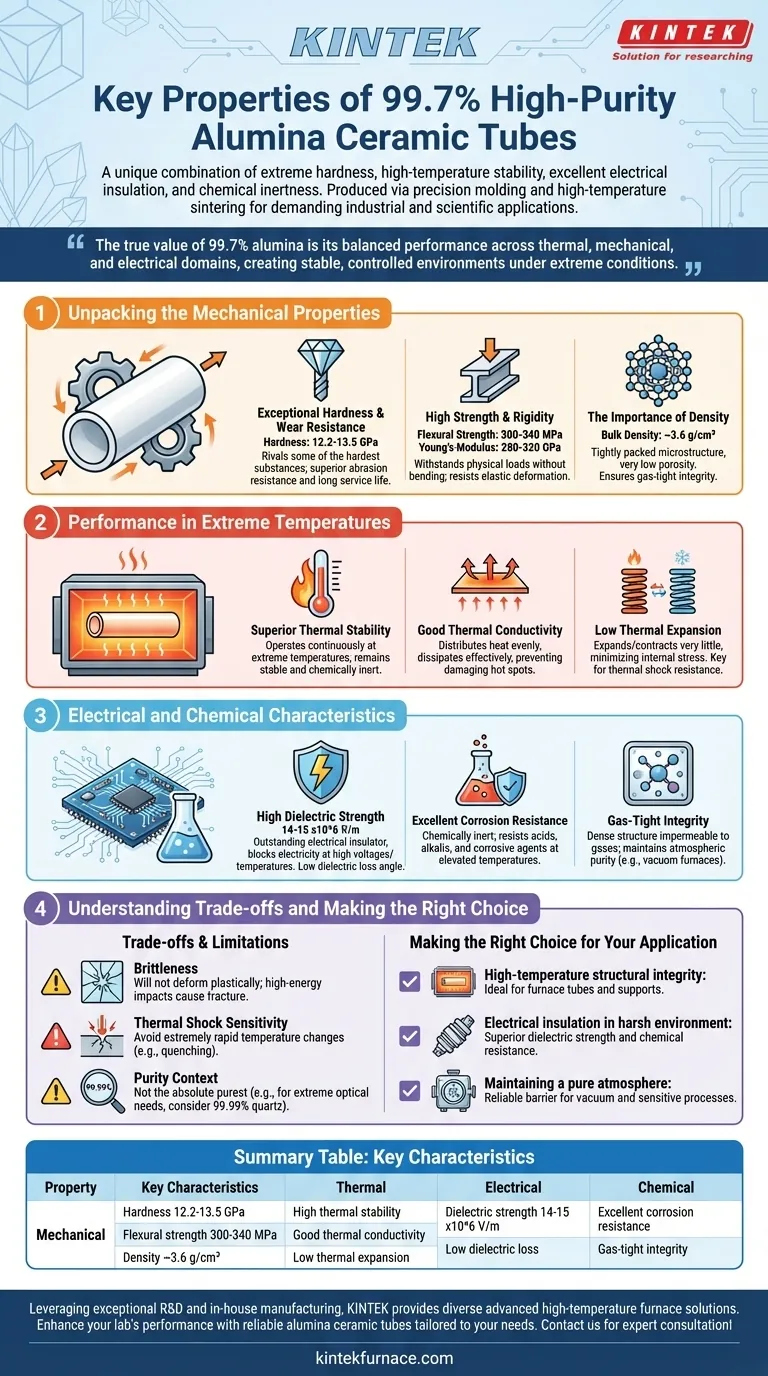

In essence, 99.7% high-purity alumina ceramic tubes are defined by a unique combination of extreme hardness, high-temperature stability, excellent electrical insulation, and chemical inertness. Produced through a process of precision molding and high-temperature sintering, these properties make them a reliable material for some of the most demanding industrial and scientific applications.

The true value of 99.7% alumina is not in one single property, but in its balanced performance across thermal, mechanical, and electrical domains. This makes it a foundational material for creating stable, controlled environments under extreme conditions.

Unpacking the Mechanical Properties

The mechanical integrity of alumina tubes is central to their function in structural and high-wear applications. This is not just about strength, but a combination of hardness, rigidity, and density.

Exceptional Hardness and Wear Resistance

With a hardness of 12.2-13.5 GPa, high-purity alumina is an exceptionally hard material, rivaling some of the hardest substances known.

This intrinsic hardness directly translates to superior wear and abrasion resistance, ensuring a long service life in environments with abrasive particles or physical contact.

High Strength and Rigidity

Alumina exhibits high compressive strength and a flexural strength between 300-340 MPa. This means it can withstand significant physical loads without bending or breaking.

Its rigidity is quantified by a high Young's Modulus (280-320 GPa), indicating that it resists elastic deformation under stress, maintaining its precise shape.

The Importance of Density

A bulk density of around 3.6 g/cm³ signifies a tightly packed microstructure with very low porosity.

This density is the reason alumina tubes are gas-tight, a critical feature for maintaining a vacuum or a controlled, protective atmosphere in high-temperature furnaces.

Performance in Extreme Temperatures

Alumina's behavior at high temperatures is arguably its most recognized characteristic, making it the material of choice for furnaces, kilns, and thermal processing.

Superior Thermal Stability

These tubes are designed to operate continuously at extreme temperatures, remaining stable and chemically inert in environments where most metals would fail.

Good Thermal Conductivity

Unlike many ceramics that are thermal insulators, alumina has good thermal conductivity. This allows it to distribute heat evenly and dissipate it effectively, preventing damaging hot spots.

Low Thermal Expansion

Alumina has a low coefficient of thermal expansion. This means it expands and contracts very little when heated or cooled, which minimizes internal stress and is a key factor in its thermal shock resistance.

Electrical and Chemical Characteristics

Beyond its physical robustness, alumina's electrical and chemical properties are essential for applications in electronics, semiconductor manufacturing, and chemical processing.

High Dielectric Strength

With a dielectric strength of 14-15 x10^6 V/m, alumina is an outstanding electrical insulator. It effectively blocks the flow of electricity, even at high voltages and temperatures.

This property, combined with a low dielectric loss angle, makes it ideal for insulators, sensor housings, and components in high-frequency devices.

Excellent Corrosion Resistance

High-purity alumina is chemically inert and exhibits excellent corrosion resistance against a wide range of acids, alkalis, and other corrosive agents, even at elevated temperatures.

Gas-Tight Integrity

As mentioned, the dense structure makes these tubes impermeable to gases. This is non-negotiable for applications like semiconductor processing or metallurgy where atmospheric purity is paramount.

Understanding the Trade-offs and Limitations

No material is perfect. Acknowledging the trade-offs inherent in alumina is key to successful implementation and avoiding failure.

Brittleness vs. Hardness

The primary trade-off for alumina's extreme hardness is its brittleness. Unlike metals, it will not deform plastically. A sharp, high-energy impact can cause it to fracture rather than dent.

Thermal Shock Sensitivity

While it has good thermal shock resistance due to low expansion, alumina can still crack if subjected to extremely rapid temperature changes (e.g., quenching a red-hot tube in water). Heating and cooling rates must be managed.

Purity in Context

While 99.7% is considered high-purity and suitable for most applications, it is not the absolute purest ceramic available. For the most demanding semiconductor or optical applications, materials like 99.99% pure quartz may be required to avoid even trace contaminants.

Making the Right Choice for Your Application

Selecting alumina requires matching its specific strengths to your primary engineering challenge.

- If your primary focus is high-temperature structural integrity: Its combination of high flexural strength, thermal stability, and low thermal expansion makes it an ideal choice for furnace tubes and support structures.

- If your primary focus is electrical insulation in a harsh environment: Its high dielectric strength, coupled with excellent corrosion and heat resistance, makes it superior to most polymers or other insulators.

- If your primary focus is maintaining a pure atmosphere: Its gas-tight nature and chemical inertness provide a reliable barrier for vacuum furnaces, gas processing, and sensitive chemical reactions.

By understanding this balance of properties, you can confidently specify 99.7% alumina ceramic tubes for applications where reliability under pressure is non-negotiable.

Summary Table:

| Property | Key Characteristics |

|---|---|

| Mechanical | Hardness: 12.2-13.5 GPa, Flexural strength: 300-340 MPa, Density: ~3.6 g/cm³ |

| Thermal | High thermal stability, Good thermal conductivity, Low thermal expansion |

| Electrical | Dielectric strength: 14-15 x10^6 V/m, Low dielectric loss |

| Chemical | Excellent corrosion resistance, Gas-tight integrity |

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Enhance your lab's performance with reliable alumina ceramic tubes tailored to your needs—contact us today for expert consultation!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What is flash vacuum pyrolysis and how is a tube furnace utilized in this process? Unlock High-Temp Chemical Reactions

- How does a tube heating furnace facilitate the carbon coating process? Boost Layered Oxide Conductivity

- What are the material requirements for furnace tubes? Optimize Performance and Safety in High-Temperature Labs

- What function does a tube furnace serve in the PVT growth of J-aggregate molecular crystals? Mastery of Thermal Control

- How do roller kilns and tube furnaces differ in their use of Alumina ceramic tubes? Compare Transport vs. Containment