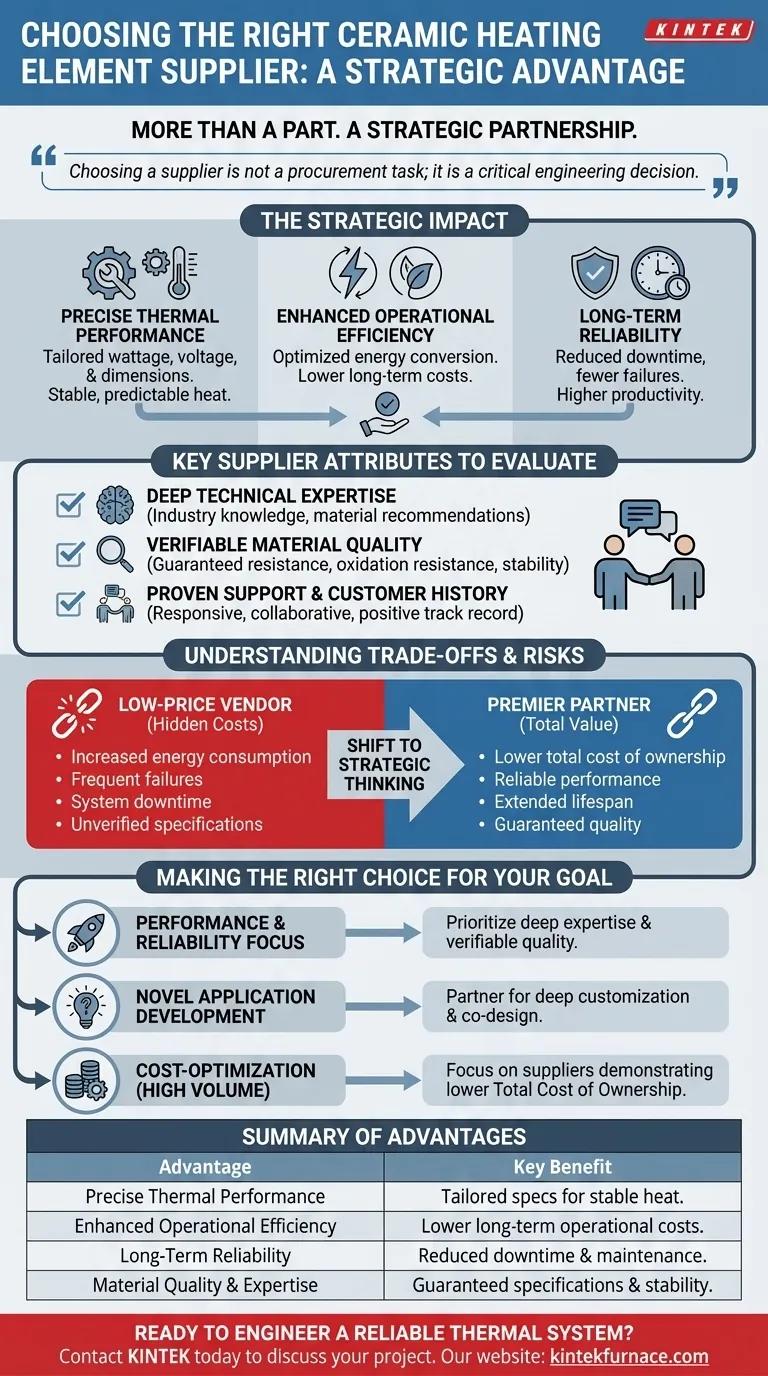

Ultimately, the right ceramic heating element supplier provides more than just a component; they deliver a strategic advantage. Choosing the right partner ensures you receive a customized solution that improves energy efficiency, reduces operational downtime, and provides stable, high-temperature performance tailored precisely to your application's needs.

Choosing a supplier is not a procurement task; it is a critical engineering decision. The difference between a premier supplier and a low-cost vendor lies in the gap between simply acquiring a part and engineering a reliable, efficient thermal system.

The Strategic Impact of a Quality Supplier

Selecting a supplier has direct consequences on your product's performance, reliability, and total cost of ownership. A premier partner acts as an extension of your engineering team.

Achieving Precise Thermal Performance

A top-tier supplier works with you to define exact specifications. This includes tailoring the element's wattage, voltage, and physical dimensions to fit your device perfectly.

The result is stable, predictable heat generation, which is critical for processes that require consistent high temperatures without fluctuations.

Enhancing Operational Efficiency

An expertly engineered ceramic heater is designed for optimal energy efficiency. It converts a higher percentage of electricity into usable heat, reducing wasted energy and lowering long-term operational costs.

This is achieved through careful material selection and design that matches the element's properties to the system's thermal demands.

Ensuring Long-Term Reliability

The most significant operational benefit is a sharp reduction in downtime. High-quality elements sourced from a reputable supplier are more durable and have a longer operational lifespan.

Fewer failures mean fewer service calls, less maintenance, and higher productivity for the end-user, directly enhancing your product's reputation.

Key Supplier Attributes to Evaluate

Beyond the product itself, the supplier's capabilities are what guarantee success. Look for these clear indicators of quality.

Deep Technical Expertise

An experienced supplier possesses deep industry knowledge and can guide you toward the best solution, often identifying potential issues before they arise.

They understand the nuances of different materials and can recommend the ideal composition for your specific thermal and environmental challenges.

Verifiable Material Quality

The core of a heating element's performance lies in its material properties. A good supplier provides transparency and guarantees specifications such as:

- Electrical Resistance: The material must have high resistance to generate heat effectively but not be an insulator. Its temperature coefficient of resistance should also be low and predictable.

- Oxidation Resistance: The element must withstand high temperatures without degrading. This is often achieved with protective silicon or aluminum oxide coatings.

- Mechanical Stability: The material must be ductile enough to be formed into the required shape but also resist deformation or sagging at peak operating temperatures.

- High Melting Point: A fundamental requirement is a melting point far above the operating temperature to ensure the element remains solid and functions efficiently.

Proven Support and Customer History

Look for suppliers with a track record of positive customer reviews and responsive support services. A willingness to collaborate and troubleshoot is the hallmark of a true partner.

Understanding the Trade-offs and Risks

Choosing a supplier based solely on initial price is one of the most common and costly mistakes in system design.

The Hidden Costs of a Low-Price Supplier

A cheaper, lower-quality heating element often leads to a higher total cost of ownership. The initial savings are quickly erased by increased energy consumption, frequent failures, and the cost of system downtime.

Inconsistent performance from cheap elements can also ruin product batches in manufacturing or lead to unreliable device operation, damaging your brand's reputation.

The Risk of Unverified Specifications

Without a trustworthy supplier, you have no guarantee that the materials used meet critical specifications. An element that oxidizes prematurely or deforms under heat can cause catastrophic system failure.

A quality supplier provides documentation and stands behind the material science of their product, removing this significant risk.

Making the Right Choice for Your Goal

Your final decision should be aligned with your project's most critical priority.

- If your primary focus is performance and reliability: Prioritize suppliers with deep technical expertise and verifiable material quality to ensure long-term, stable operation.

- If your primary focus is developing a novel application: Partner with a supplier who offers deep customization and collaborative engineering support to co-design the perfect solution.

- If your primary focus is cost-optimization for high-volume production: Focus on suppliers who can demonstrate how their element's efficiency and reliability lower your total cost of ownership, not just the initial component price.

Choosing your supplier is a decision that defines the quality and reliability of your final product.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Precise Thermal Performance | Tailored wattage, voltage, and dimensions for stable, predictable heat. |

| Enhanced Operational Efficiency | Optimized energy conversion lowers long-term operational costs. |

| Long-Term Reliability | Durable elements reduce downtime and maintenance needs. |

| Material Quality & Expertise | Guaranteed specifications for resistance, oxidation resistance, and stability. |

Ready to engineer a reliable, efficient thermal system?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse industries with advanced high-temperature heating solutions. Our product line, including Muffle, Tube, and Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique thermal requirements.

Contact KINTEK today to discuss how our ceramic heating elements can become a strategic advantage for your project.

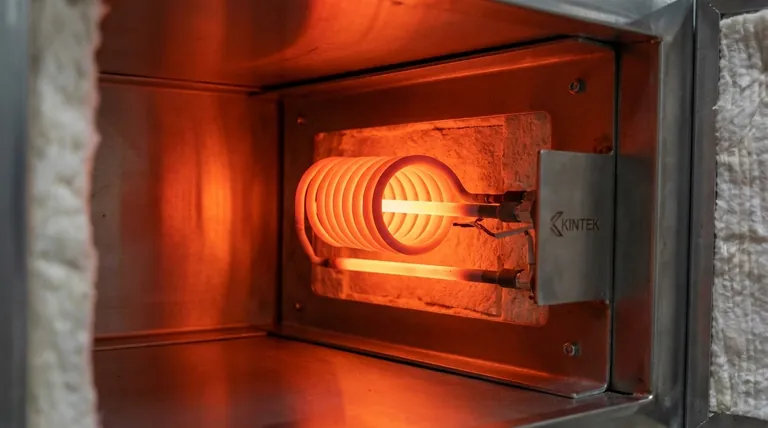

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the operating temperature of SiC? Unlock Reliable Performance Up to 1600°C

- What are the advantages of silicon carbide heating elements in dental furnaces? Boost Zirconia Sintering Quality

- What parameters does the IEC standard specify for heating elements? Ensure Safety and Performance

- What is the temperature range for silicon carbide heating elements? Unlock High-Temp Performance from 600°C to 1625°C

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability