In practice, molybdenum heating elements come in two distinct categories that dictate their form and function. While the basic physical configurations are wire, rod, and strip for pure molybdenum, the more critical distinction is between pure molybdenum and molybdenum disilicide (MoSi2) elements, which are chosen based on the furnace's operating temperature and atmosphere.

The core decision is not about the physical shape of the element, but about matching the material to the operating environment. Pure molybdenum is the standard for high-temperature vacuum furnaces, while molybdenum disilicide (MoSi2) is the choice for extreme-temperature applications in oxidizing atmospheres like air.

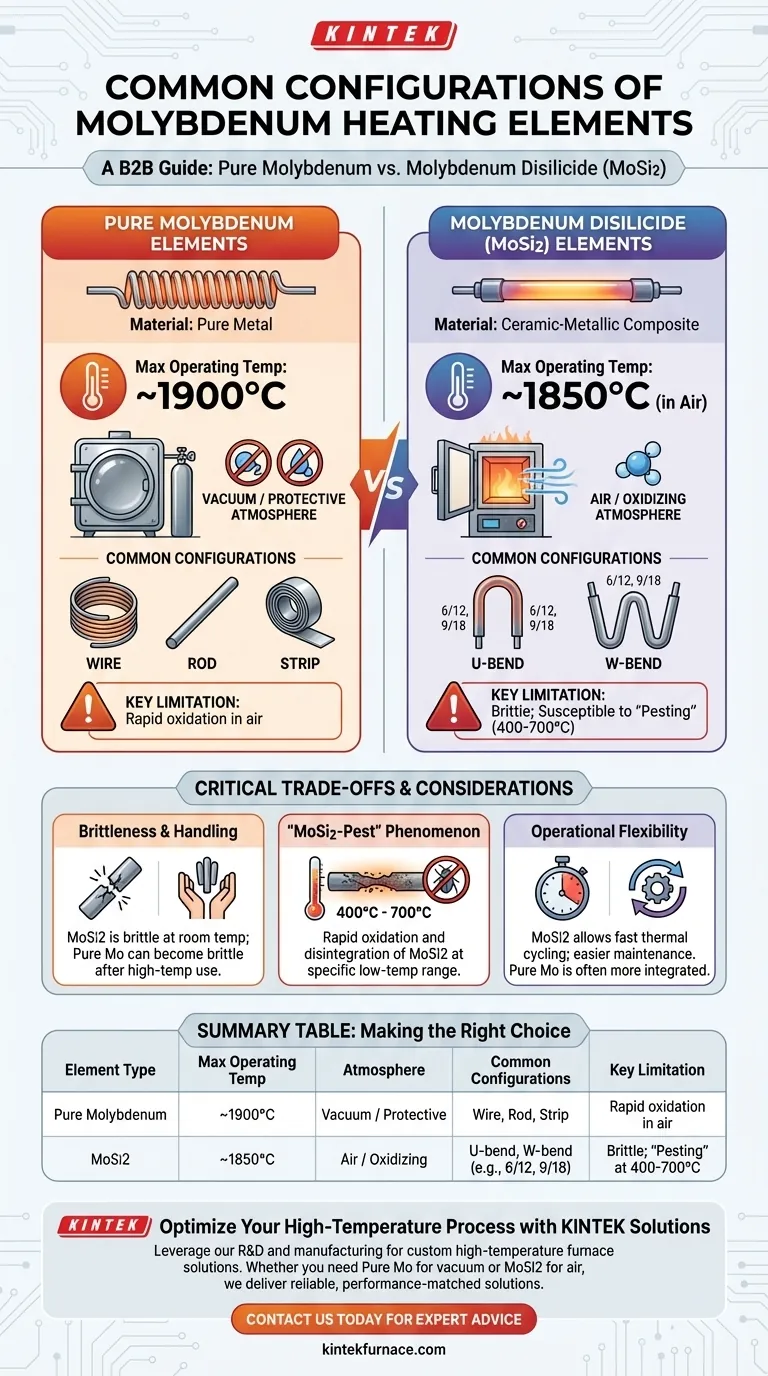

Understanding the Two Primary Types

To select the correct configuration, you must first understand the fundamental differences between the two main types of molybdenum-based heating elements. They are not interchangeable.

Pure Molybdenum Elements

Pure molybdenum elements are valued for their high mechanical strength and a very high melting point of 2623°C. This allows for peak operating temperatures around 1900°C.

These elements are most often manufactured in simple, versatile shapes like wire, rod, and strip. This allows for custom configurations within a furnace.

Their primary limitation is a susceptibility to oxidation. They must be used in a vacuum or a protective, reducing atmosphere. Exposure to oxygen at high temperatures will rapidly destroy them.

Molybdenum Disilicide (MoSi2) Elements

MoSi2 is a ceramic-metallic composite, not a pure metal. It is designed specifically for its exceptional resistance to oxidation at extreme temperatures.

These elements boast the highest operating temperatures, reaching up to 1850°C in air. They have a stable resistance over their lifetime, allowing new and old elements to be used together.

MoSi2 elements typically come in pre-formed shapes, often a "U" or "W" bend, and are specified by diameter codes like 6/12 or 9/18.

Matching the Element to the Environment

The success or failure of your heating system depends entirely on choosing the element that can survive its intended operating conditions.

The Critical Role of Atmosphere

This is the most important factor. If your process occurs in a vacuum or a controlled hydrogen/inert gas atmosphere, you should use pure molybdenum.

If your furnace operates in air or another oxidizing environment, you must use molybdenum disilicide (MoSi2).

Temperature Range Considerations

Pure molybdenum is excellent for moderate-to-high temperature processes like hardening and brazing, typically operating up to 1900°C.

MoSi2 excels at the highest end of the spectrum, with typical application temperatures starting around 1200°C and going up to 1850°C.

Understanding the Trade-offs and Limitations

No material is perfect. Acknowledging the inherent weaknesses of each type is critical for reliable operation and avoiding costly failures.

Brittleness and Handling

Both materials require careful handling. MoSi2 is very brittle at room temperature and can be easily damaged during installation.

Pure molybdenum maintains good strength but can become brittle if operated above its maximum recommended temperature.

The 'MoSi2-Pest' Phenomenon

This is a critical failure mode unique to MoSi2 elements. In a specific low-temperature range (approximately 400°C to 700°C), the material can rapidly oxidize and disintegrate into a powder.

Furnaces using MoSi2 elements must be programmed to heat or cool through this temperature range quickly to prevent 'pesting'.

Operational Flexibility

MoSi2 offers significant operational advantages. Its stable resistance allows for fast thermal cycling, and failed elements can often be replaced while the furnace is still hot.

Pure molybdenum elements are less forgiving and are typically part of a more integrated furnace design, making replacement more involved.

Making the Right Choice for Your Application

Your process requirements will point directly to the correct element type.

- If your primary focus is vacuum or controlled atmosphere processes: Pure molybdenum in wire, rod, or strip form is the industry standard for its strength and high-temperature capability.

- If your primary focus is extreme-temperature (1200°C+) air furnace applications: Molybdenum disilicide (MoSi2) is the only viable choice due to its oxidation resistance.

- If your primary focus is operational uptime and long life in air: MoSi2 provides the longest inherent life and allows for easier maintenance, like mixing old and new elements.

Ultimately, selecting the right element is about choosing the material designed to survive your specific thermal and atmospheric environment.

Summary Table:

| Element Type | Max Operating Temp | Atmosphere | Common Configurations | Key Limitation |

|---|---|---|---|---|

| Pure Molybdenum | ~1900°C | Vacuum / Protective | Wire, Rod, Strip | Rapid oxidation in air |

| Molybdenum Disilicide (MoSi2) | ~1850°C | Air / Oxidizing | U-bend, W-bend (e.g., 6/12, 9/18) | Brittle; susceptible to 'pesting' at 400-700°C |

Optimize Your High-Temperature Process with KINTEK Solutions

Choosing between pure molybdenum and molybdenum disilicide heating elements is critical for your furnace's performance and longevity. At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced, high-temperature furnace solutions tailored to your unique requirements.

Our product line includes Muffle Furnaces, Tube Furnaces, and Vacuum & Atmosphere Furnaces, all designed with the deep customization capabilities needed to precisely match your specific thermal and atmospheric conditions. Whether you require the strength of pure molybdenum for vacuum applications or the extreme temperature resistance of MoSi2 for air atmospheres, we can deliver a reliable, high-performance solution.

Let our experts help you select the perfect heating element configuration for your lab.

Contact us today to discuss your application and discover how KINTEK's expertise can enhance your process efficiency and reliability.

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- Why is a high vacuum essential for Ti-6Al-4V sintering? Protect Your Alloys from Embrittlement

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?