While resistance is fundamental to electrical heating, it is not the only factor. The amount of heat an element produces is a function of both its resistance and the electrical current flowing through it. More importantly, an element's resistance is not an independent variable; it is a result of other critical design choices, including the material it's made from and its physical dimensions.

Focusing solely on resistance misses the point. The true goal is to design a component that can safely and consistently produce the required heat, which involves a careful balance of the material's properties, its physical shape, and the electrical current applied.

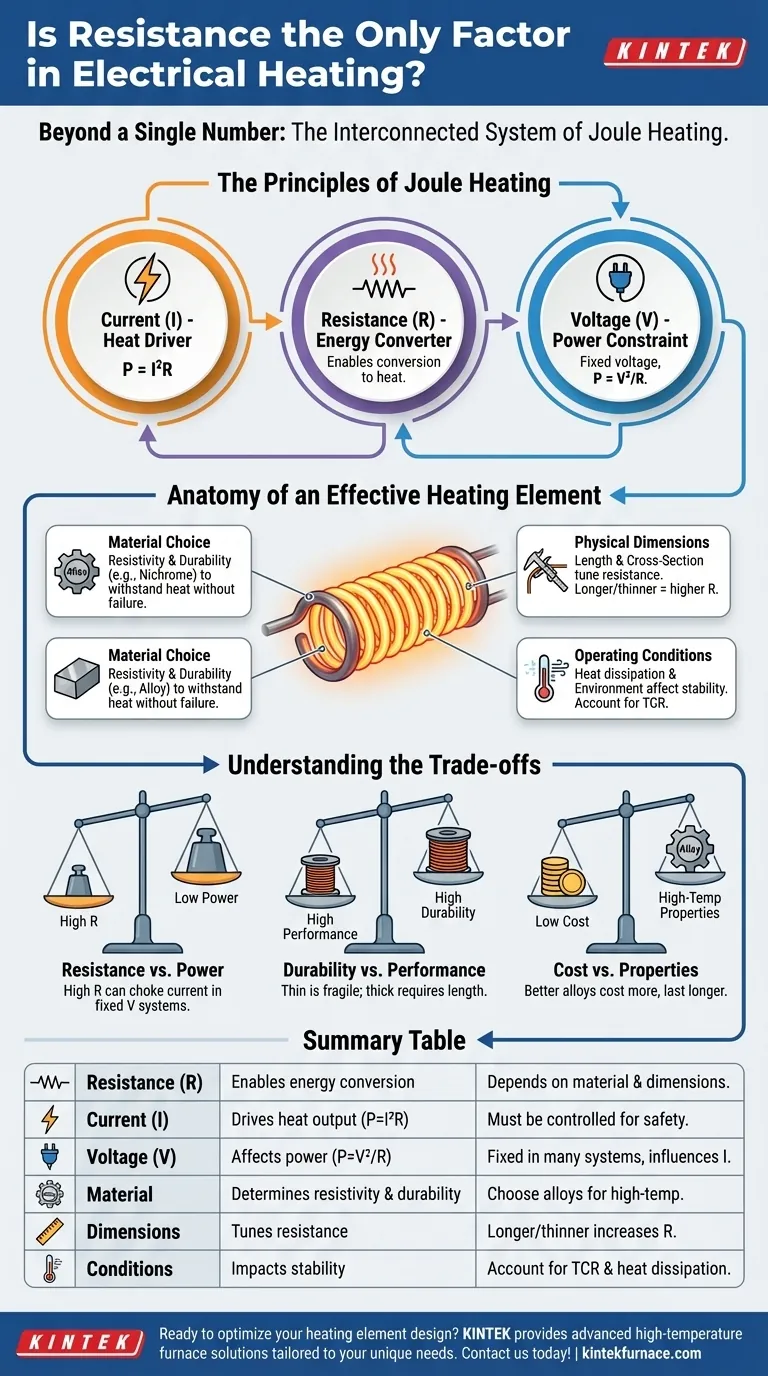

Beyond a Single Number: The Principles of Joule Heating

Electrical heating, or Joule heating, is often simplified to just "resistance." However, resistance is only one part of an interconnected system. Understanding how it interacts with current and voltage is essential.

The Role of Current (I)

The power dissipated as heat is proportional to the square of the current (P = I²R). This means that doubling the current quadruples the heat output, making current the most powerful driver of heat generation.

In any heating element design, controlling or predicting the current is just as important as setting the resistance.

The Role of Resistance (R)

Resistance is the property that enables the conversion of electrical energy into thermal energy. For a given amount of current, a higher resistance will produce more heat.

A material with zero resistance would produce no heat at all, no matter how much current passed through it. Therefore, a heating element must have sufficient internal resistance to function.

The Critical Influence of Voltage (V)

In many real-world applications, like plugging a device into a wall outlet, the voltage is fixed. This creates a crucial relationship defined by Ohm's Law (V = IR).

Because voltage (V) is constant, a higher resistance (R) will actually decrease the current (I) that can flow. This leads to a different power equation: P = V²/R. This reveals a counter-intuitive fact: for a fixed voltage source, lowering the resistance increases the current and therefore increases the power output.

The Anatomy of an Effective Heating Element

The "resistance" of a heating element is not a number you choose from a catalog. It is the result of deliberate engineering decisions about its physical and material makeup.

Material Choice: Resistivity and Durability

Resistivity is an intrinsic property of a material that measures how strongly it opposes the flow of electricity. Materials like Nichrome or Kanthal are chosen not just for their high resistivity, but for their ability to withstand very high temperatures without oxidizing, melting, or becoming brittle.

Physical Dimensions: Length and Cross-Sectional Area

For a given material, resistance is determined by its shape. A longer, thinner wire will have higher resistance than a shorter, thicker one.

Designers use this principle to "tune" an element. They select a durable material and then calculate the precise length and diameter needed to achieve the target resistance that will produce the desired heat output with the available voltage and current.

Operating Conditions: Heat and Environment

The resistance of most materials changes with temperature. This property, known as the Temperature Coefficient of Resistance (TCR), must be accounted for in precision applications.

Furthermore, how quickly an element dissipates its heat into the surrounding environment (air, water, etc.) determines its stable operating temperature. An element that can't shed heat fast enough will see its temperature rise uncontrollably and ultimately fail.

Understanding the Trade-offs

Designing a heating element is a process of balancing competing factors. Focusing on just one variable, like maximizing resistance, often leads to failure.

The High Resistance vs. High Power Myth

As we saw with fixed-voltage systems (P = V²/R), an extremely high resistance will choke off current and lead to very low power output. The goal is not maximum resistance, but the optimal resistance that draws the desired current from the power source without exceeding safety limits.

Durability vs. Performance

A very thin wire provides high resistance in a compact form, but it is mechanically fragile and has a smaller surface area, making it prone to overheating and burnout. A thicker wire is more robust and durable but will have a lower resistance, requiring design adjustments (like a much greater length) to achieve the same power output.

Cost vs. Material Properties

High-performance alloys that operate reliably at extreme temperatures are significantly more expensive than simpler materials like stainless steel. The choice depends entirely on the application's required lifespan and operating temperature.

Making the Right Choice for Your Goal

To design or select an effective heating component, you must first define your primary objective.

- If your primary focus is maximum heat from a fixed voltage source (like a wall outlet): You need to find the optimal resistance that allows the maximum safe current to flow, which often means a lower resistance than you might intuitively think.

- If your primary focus is durability and long life: Choose a material with excellent high-temperature oxidation resistance and use a thicker gauge wire, designing the element's length to compensate for the lower resistance.

- If your primary focus is precision temperature control: Select a material with a stable and predictable resistance across its operating temperature range and consider how it will be integrated into a control system.

Ultimately, effective heating element design is a system-level challenge of balancing material science, electrical principles, and physical form.

Summary Table:

| Factor | Role in Electrical Heating | Key Considerations |

|---|---|---|

| Resistance (R) | Enables energy conversion to heat | Depends on material resistivity and physical dimensions |

| Current (I) | Drives heat output (P = I²R) | Must be controlled for safety and performance |

| Voltage (V) | Fixed in many systems, affects power (P = V²/R) | Influences current flow and overall heat generation |

| Material Properties | Determines resistivity and durability | Choose alloys like Nichrome for high-temperature resistance |

| Physical Dimensions | Length and cross-sectional area tune resistance | Longer, thinner wires increase resistance but may reduce durability |

| Operating Conditions | Temperature and environment impact stability | Account for TCR and heat dissipation to prevent failure |

Ready to optimize your heating element design? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities. Whether you're aiming for maximum heat output, enhanced durability, or precise temperature control, we can help you achieve reliable and efficient performance. Contact us today to discuss how our expertise can benefit your laboratory!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating