A forced convection drying oven is the critical tool for establishing a precise experimental baseline. It ensures that concrete disc specimens are heated until they achieve a constant weight, effectively removing all pre-existing moisture from the material. This rigorous drying process provides the standardized starting point necessary to accurately calculate subsequent moisture absorption rates.

Establishing a consistent dry baseline allows researchers to isolate variables. This ensures that observed changes in water absorption are strictly due to material properties, such as the pore-refining effects of ultra-fine rice husk ash, rather than previous moisture content.

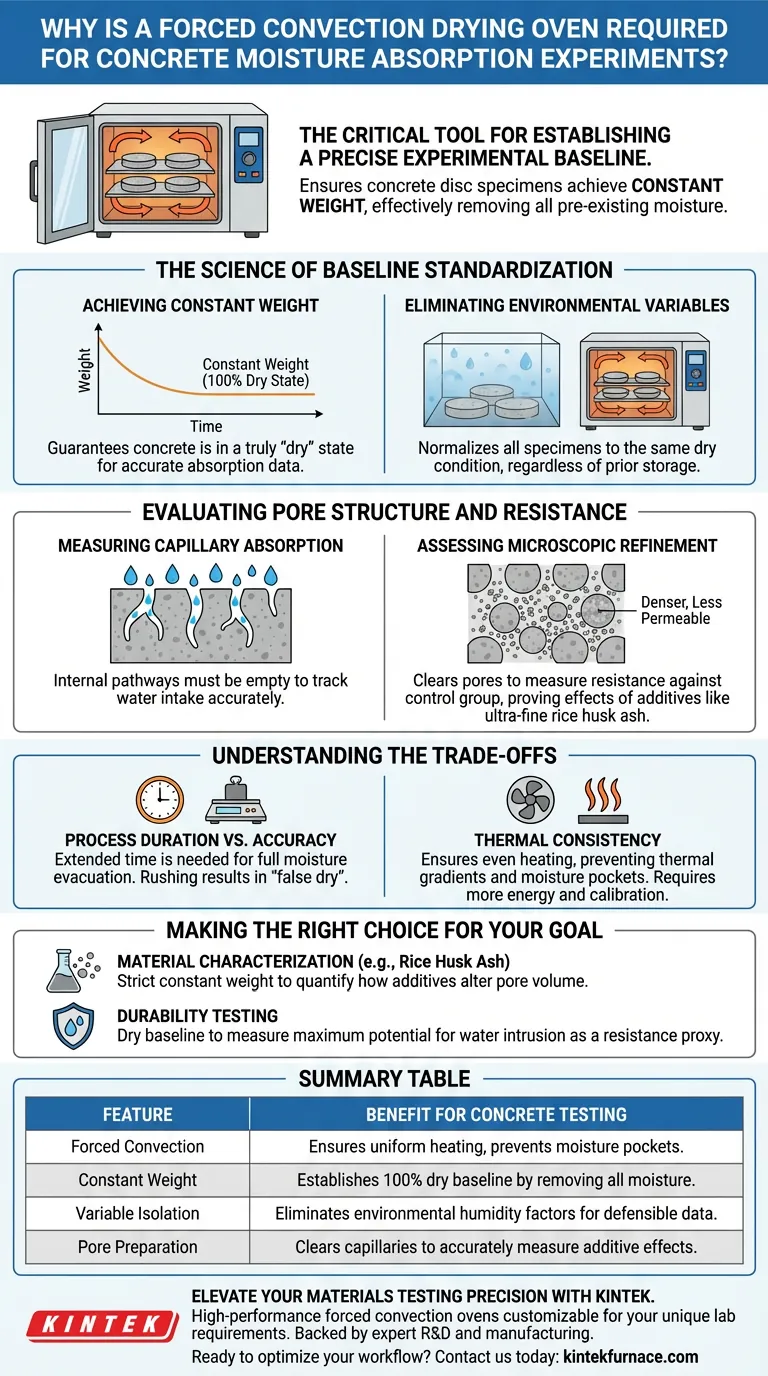

The Science of Baseline Standardization

Achieving Constant Weight

The primary function of the forced convection oven is to drive out moisture until the specimen's weight creates a flat line.

If a specimen retains moisture before testing begins, the final absorption data will be skewed. Reaching a constant weight guarantees that the concrete is in a truly "dry" state.

Eliminating Environmental Variables

Concrete is hygroscopic and naturally absorbs moisture from the air.

Without a forced convection drying cycle, specimens stored in different humidity conditions would yield inconsistent results. The oven normalizes all specimens to the same dry condition, regardless of their prior storage environment.

Evaluating Pore Structure and Resistance

Measuring Capillary Absorption

The experiment described aims to evaluate how water penetrates the concrete.

To measure capillary water absorption accurately, the internal pathways (capillaries) must be empty. This allows researchers to track exactly how much water the material draws in over time.

Assessing Microscopic Refinement

The use of additives, such as ultra-fine rice husk ash, is intended to change the microstructure of the concrete.

This ash works by refining the microscopic pore structure, making the concrete denser and less permeable. The drying process is essential to prove this theory; it clears the pores so that resistance to penetration can be measured effectively against the control group.

Understanding the Trade-offs

Process Duration vs. Accuracy

Achieving a constant weight is not a fast process.

It requires extended time in the oven to ensure moisture is fully evacuated from deep within the disc. Rushing this step results in a "false dry" state, rendering the absorption data invalid.

Thermal Consistency

Forced convection is preferred over static heating because it ensures even temperature distribution.

Uneven heating could cause thermal gradients that might damage the specimen or leave moisture pockets in the center of the disc. The trade-off is that this equipment requires more energy and precise calibration than simple air drying.

Making the Right Choice for Your Goal

To ensure your moisture absorption data is defensible, align your drying process with your specific experimental objectives.

- If your primary focus is material characterization: Ensure specimens reach strict constant weight to accurately quantify how additives like rice husk ash alter pore volume.

- If your primary focus is durability testing: Use the dry baseline to measure the maximum potential for water intrusion, which acts as a proxy for the material's resistance to penetration.

Precision in the drying phase is the only way to guarantee accuracy in the absorption phase.

Summary Table:

| Feature | Benefit for Concrete Testing |

|---|---|

| Forced Convection | Ensures uniform heating and prevents moisture pockets in disc centers. |

| Constant Weight | Establishes a 100% dry baseline by removing all pre-existing moisture. |

| Variable Isolation | Eliminates environmental humidity factors for consistent, defensible data. |

| Pore Preparation | Clears capillaries to accurately measure the effects of additives like rice husk ash. |

Elevate Your Materials Testing Precision with KINTEK

Don’t let inconsistent baselines compromise your research. Backed by expert R&D and manufacturing, KINTEK offers high-performance forced convection ovens, Muffle, Tube, Rotary, and Vacuum systems—all customizable for your unique lab requirements. Whether you are characterizing pore structures or testing durability, our high-temp solutions provide the thermal consistency your specimens demand.

Ready to optimize your experimental workflow? Contact us today to discover how our specialized equipment can bring unmatched accuracy to your laboratory.

Visual Guide

References

- Roz‐Ud‐Din Nassar, Shah Room. Strength, Durability, and Microstructural Characteristics of Binary Concrete Mixes Developed with Ultrafine Rice Husk Ash as Partial Substitution of Binder. DOI: 10.13189/cea.2025.130137

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the significance of applying full displacement constraints at fixed entry points? Ensure Thermal Accuracy

- Why is a high-precision programmed heating system used for catalyst stability? Ensure Precise Reactor Data Integrity

- What are the advantages and disadvantages of dental porcelain? Achieve a Perfect Balance of Aesthetics & Durability

- How is a precision micro-Raman spectrometer utilized in the characterization of SSBSN ceramics? Master Phase Verification

- Why is a heating furnace set to 155 °C for sulfur melt-diffusion? Unlock Optimal Battery Material Synthesis

- What is the purpose of preheating reinforcement particles? Optimize AMC Stir Casting Results

- Why are different cooling methods compared for GFRP post-fire performance? Evaluate Thermal Shock & Safety Risks

- Why must the casting dispersion be treated in a 100°C drying oven? Ensure Perfect Film Morphology