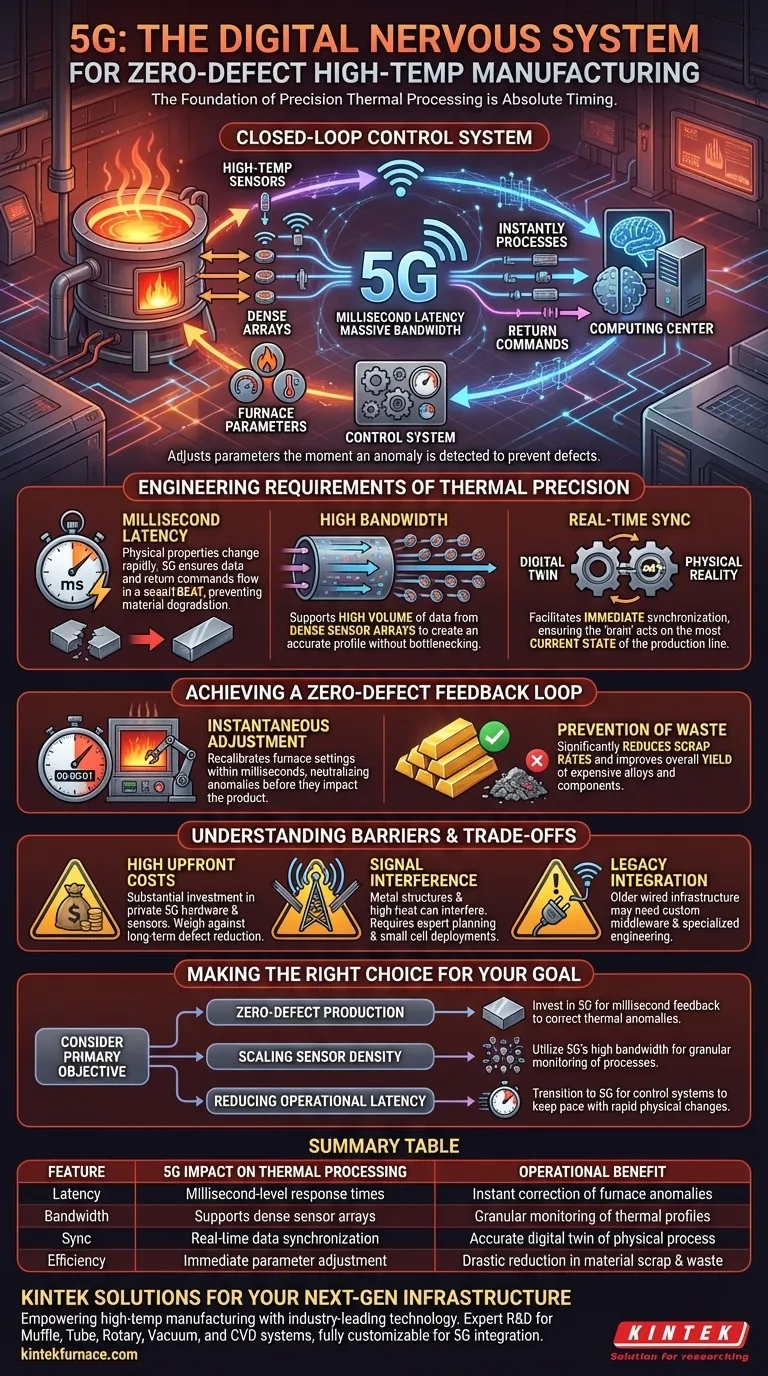

The foundation of precision thermal processing is absolute timing. 5G network infrastructure is critical because it provides the millisecond-level latency and massive bandwidth required for instantaneous data synchronization between high-temperature sensors and control systems. This allows manufacturers to close the feedback loop in real-time, adjusting furnace parameters the moment an anomaly is detected to prevent defects.

5G acts as the "digital nervous system" for high-temperature manufacturing, enabling a closed-loop control system that reacts in real-time. By reducing response times to milliseconds, it transforms quality control from a retrospective post-mortem into a preventative, zero-defect strategy.

The Engineering Requirements of Thermal Precision

The Critical Role of Millisecond Latency

In high-temperature environments, physical properties change rapidly, and even a few seconds of delay can lead to material degradation. 5G’s low latency ensures that sensor data reaches the computing center and return commands reach the furnace in a single, seamless heartbeat.

High Bandwidth for Dense Sensor Arrays

Precision thermal processing requires a high volume of data from multiple points to create an accurate profile of the furnace environment. 5G provides the bandwidth necessary to handle these massive, simultaneous data streams without bottlenecking the decision-making engine.

Real-Time Data Synchronization

For quality control to be effective, the digital twin of the manufacturing process must match the physical reality perfectly. 5G facilitates immediate synchronization, ensuring that the "brain" of the factory is always acting on the most current state of the production line.

Achieving a Zero-Defect Feedback Loop

Instantaneous Parameter Adjustment

When a sensor detects a deviation in temperature or atmospheric pressure, the system must react immediately. A 5G-enabled system can complete this feedback loop and recalibrate furnace settings within milliseconds, neutralizing the anomaly before it impacts the product.

Prevention of Costly Material Waste

High-temperature processes often involve expensive alloys or components that are easily ruined by thermal fluctuations. By utilizing 5G for real-time quality control, manufacturers can significantly reduce scrap rates and improve overall yield.

Support for Precision Thermal Processing

Precision processing demands a level of control that older networking standards simply cannot provide. 5G is the essential hardware requirement that allows for the fine-tuned adjustments necessary for advanced metallurgy and chemical processing.

Understanding the Trade-offs and Implementation Barriers

Significant Upfront Infrastructure Costs

While 5G offers unparalleled performance, the initial investment in private 5G hardware and compatible sensors can be substantial. Organizations must weigh the long-term reduction in defect costs against these high entry points.

Signal Interference in Industrial Environments

Large metal structures and high-heat machinery can sometimes interfere with wireless signals. Ensuring reliable coverage throughout a complex manufacturing facility requires expert planning and a dense network of small cell deployments.

Integration with Legacy Systems

Many high-temperature manufacturing plants rely on older, wired infrastructure that may not be natively compatible with 5G. Bridging the gap between legacy hardware and modern wireless networks often requires custom middleware and specialized engineering.

Making the Right Choice for Your Goal

When evaluating the transition to a 5G-enabled manufacturing environment, consider your primary operational objective:

- If your primary focus is Zero-Defect Production: Invest in 5G to enable the millisecond feedback loops required to correct thermal anomalies before they result in scrap.

- If your primary focus is Scaling Sensor Density: Utilize 5G’s high bandwidth to integrate more sensors per square foot, providing a more granular view of your high-temperature processes.

- If your primary focus is Reducing Operational Latency: Transition from Wi-Fi or wired setups to 5G to ensure your control systems can keep pace with the rapid physical changes inherent in thermal processing.

The shift to 5G infrastructure is the definitive step toward a future where high-temperature manufacturing is governed by absolute precision rather than reactive correction.

Summary Table:

| Feature | 5G Impact on Thermal Processing | Operational Benefit |

|---|---|---|

| Latency | Millisecond-level response times | Instant correction of furnace anomalies |

| Bandwidth | Supports dense sensor arrays | Granular monitoring of thermal profiles |

| Sync | Real-time data synchronization | Accurate digital twin of physical process |

| Efficiency | Immediate parameter adjustment | Drastic reduction in material scrap & waste |

Revolutionize Your Thermal Precision with KINTEK

Don't let latency compromise your material quality. KINTEK empowers your high-temperature manufacturing with industry-leading technology. Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to integrate with your next-generation 5G infrastructure.

Whether you are scaling sensor density or targeting a zero-defect production line, our lab high-temp furnaces provide the stability and precision your data demands.

Ready to upgrade your thermal processing capabilities? Contact KINTEK Experts Today

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- Why is a graphite furnace better than a flame in AAS? Unlock Trace-Level Detection for Your Lab

- What is the primary role of the Thermal Oxidation (TO) process in Ti-6Al-4V ELI alloy? Enhancing Hardness and Wear

- How do MFCs and Precursor Bottles Work in AP-ALD? Master Precision Vapor Draw for Atomic Coatings

- What is the role of a 5% N2 + 95% H2 mixture in plasma nitriding? Enhance Fatigue Strength and Eliminate White Layers

- What is the significance of the 220 °C annealing process? Unlock High-Purity Anti-Perovskite Thin Film Synthesis

- How does high-temperature filtration equipment facilitate molten salt separation? Boost Your Slag Treatment Recovery

- Why is annealing considered a core process in perovskite solar cell manufacturing? Unlock Peak Efficiency

- What is the purpose of designing the internal control caps of a salt bath furnace with slanted upward outlets?