Secondary vulcanization is a mandatory post-processing step required to stabilize the physical and electrical properties of high-phenyl conductive silicone rubber. By subjecting the molded part to a high-temperature oven environment (typically at 200°C), this process removes volatile chemical by-products and finalizes the material's internal structure.

While initial compression molding gives the rubber its shape, secondary vulcanization acts as a critical purification and strengthening phase. It ensures the material creates a fully realized cross-linking network, preventing future degradation or failure in high-stress environments.

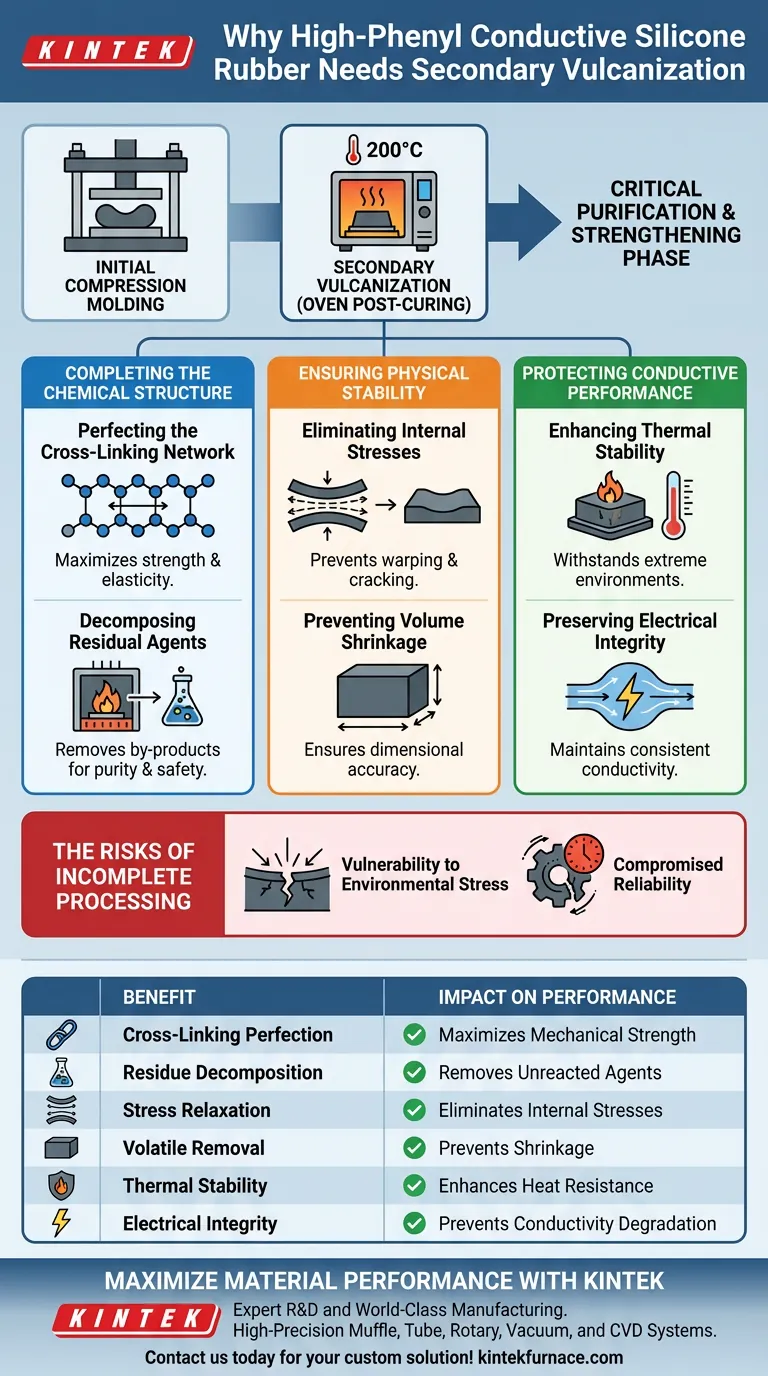

Completing the Chemical Structure

Perfecting the Cross-Linking Network

The initial molding process initiates the chemical bonds that hold the rubber together, but it rarely completes them. Secondary vulcanization drives this reaction to its absolute limit.

Exposure to maintained heat facilitates the complete perfection of the cross-linking network. This ensures the material achieves its maximum theoretical strength and elasticity.

Decomposing Residual Agents

During the primary molding phase, vulcanizing agents are introduced to cure the rubber, often leaving behind unreacted residues.

The oven process effectively decomposes these residual vulcanizing agent by-products. Eliminating these leftovers is essential for the chemical purity and safety of the final component.

Ensuring Physical Stability

Eliminating Internal Stresses

The compression molding process involves high pressure and rapid shape changes, which locks internal mechanical stresses into the material.

Secondary vulcanization acts as a relaxation phase. The heat allows polymer chains to realign, effectively eliminating internal stresses that could otherwise cause warping or cracking over time.

Preventing Volume Shrinkage

If volatile by-products remain trapped within the rubber matrix, they will eventually off-gas when the part is put into service.

By forcing these volatiles out in a controlled oven environment, manufacturers reduce the risk of unexpected volume shrinkage. This ensures the part maintains its intended dimensions even when used in high-temperature applications.

Protecting Conductive Performance

Enhancing Thermal Stability

High-phenyl silicone rubber is often selected for its ability to withstand extreme environments.

Secondary vulcanization pre-conditions the material, significantly enhancing its thermal stability. This prepares the rubber to perform reliably without degrading when exposed to operational heat.

Preserving Electrical Integrity

For conductive rubber, stability is not just mechanical; it is electrical. Residual volatiles can interfere with the conductive network within the rubber.

Removing these volatiles prevents the degradation of conductive properties. This ensures the material maintains consistent electrical performance throughout its lifespan.

The Risks of Incomplete Processing

Vulnerability to Environmental Stress

Skipping this step leaves the material chemically "unfinished." Without secondary vulcanization, the rubber retains a vulnerability to thermal shock and environmental stress that can lead to premature failure.

Compromised Reliability

The presence of residual volatiles creates a ticking clock within the material. If these are not removed during manufacturing, they may release during operation, altering the physical shape and conductivity of the component when you can least afford it.

Making the Right Choice for Your Goal

To maximize the performance of high-phenyl conductive silicone rubber, align your processing steps with your specific performance requirements:

- If your primary focus is Dimensional Precision: Prioritize this step to eliminate volatiles early, preventing volume shrinkage that could alter critical tolerances later.

- If your primary focus is Electrical Reliability: Ensure the cycle reaches the full 200°C to remove all residues that could impede conductivity or cause signal degradation.

- If your primary focus is Long-Term Durability: Use secondary vulcanization to relieve internal molding stresses, reducing the likelihood of mechanical failure under thermal load.

Secondary vulcanization converts a molded shape into a finished, engineering-grade material capable of surviving the real world.

Summary Table:

| Benefit | Impact on Material Performance |

|---|---|

| Cross-Linking Perfection | Maximizes mechanical strength and elasticity |

| Residue Decomposition | Removes unreacted agents for chemical purity |

| Stress Relaxation | Eliminates internal stresses to prevent warping |

| Volatile Removal | Prevents shrinkage and preserves dimensional accuracy |

| Thermal Stability | Enhances resistance to extreme heat environments |

| Electrical Integrity | Prevents degradation of conductive properties |

Maximize Material Performance with KINTEK

Don't let incomplete processing compromise your critical components. Backed by expert R&D and world-class manufacturing, KINTEK offers a full range of high-precision Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you need to stabilize high-phenyl conductive rubber or perfect specialized chemical structures, our lab high-temperature furnaces are fully customizable to meet your unique thermal processing needs.

Ready to enhance your lab's efficiency and reliability? Contact us today to find your custom solution!

Visual Guide

References

- Ao Liu, Chaocan Zhang. A High-Temperature-Resistant and Conductive Flexible Silicone Rubber with High Phenyl Content Based on Silver-Coated Glass Fibers. DOI: 10.3390/polym17091187

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the key differences between batch and continuous processing furnaces? Optimize Your Thermal Processing Strategy

- How does a precision temperature-controlled furnace facilitate the long-term aging treatment of Invar 36?

- Why is an industrial-grade drying oven necessary for biomass activation? Ensure Structural Integrity & Yield

- What is the primary process objective of using an electric furnace in glass experiments? Analyze Stress & Heat Transfer

- How is mechanochemical grinding used in lithium battery recovery? Unlock Efficient Solid-State Material Repair

- What is the primary value of using a thermal simulator for weather-resistant steel? Precision Hot Working Modeling

- How does a high-temperature TOC analyzer assess RCM NSs performance? Verify Mineralization vs Decolorization

- What advantages does a vacuum oven offer over a standard oven for V2CTx MXene films? Protect Your Material Quality