The synthesis of Ti-xNb biomedical alloys requires a dual-stage approach involving strict environmental control and precise thermal management. Vacuum arc furnaces are essential to prevent the catastrophic oxidation of titanium while ensuring chemical uniformity, whereas copper mold suction casting drives the rapid solidification necessary to lock in specific microstructural phases.

Core Takeaway Processing Ti-xNb alloys is not merely about melting metal; it is about managing high-temperature reactivity and controlling phase transformations. The vacuum environment guarantees purity and homogeneity by preventing contamination, while the copper mold dictates the mechanical potential of the alloy by freezing fine-grained, non-equilibrium structures.

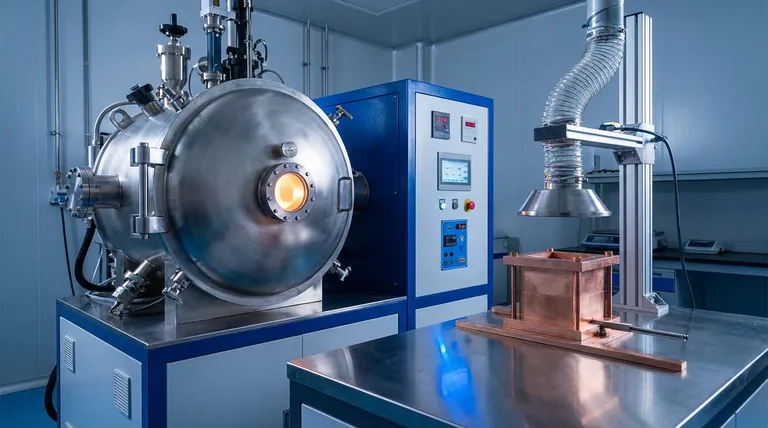

The Critical Role of the Vacuum Arc Furnace

Preventing High-Temperature Contamination

Titanium and niobium are highly reactive metals. At melting temperatures, they will react violently with oxygen and nitrogen if exposed to air.

The vacuum arc furnace utilizes high-energy arcs under vacuum or inert gas protection to create a sealed environment. This effectively prevents the formation of oxides and nitrides, which would otherwise compromise the alloy's biomedical viability.

Eliminating Volatile Impurities

Beyond preventing new contamination, the vacuum environment actively purifies the raw materials.

The process removes volatile impurity gases that may be trapped within the raw metal stock. This results in a high-purity base material essential for medical applications where biocompatibility is paramount.

Ensuring Chemical Homogeneity

Melting titanium and niobium together presents a physical challenge due to their differences in density and melting points. Simple melting can lead to macro-segregation, where elements are unevenly distributed.

To solve this, the solidified ingot is typically flipped and remelted multiple times (often three to five cycles). This utilizes convection effects within the melt pool to eliminate compositional deviations, ensuring the alloy is chemically uniform at both macroscopic and microscopic scales.

The Critical Role of Copper Mold Suction Casting

Facilitating Rapid Solidification

Once the alloy is melted and mixed, the cooling rate defines its internal structure. Copper has exceptionally high thermal conductivity, making it an ideal medium for extracting heat quickly.

When the molten alloy is suction-cast into a copper mold, it undergoes rapid solidification. This prevents the grain growth that typically occurs during slow cooling, resulting in a material with much finer structural features.

Controlling Microstructural Phases

For Ti-xNb alloys, the speed of cooling determines which crystalline phases form.

The rapid cooling provided by the copper mold promotes the formation of fine dendritic structures and non-equilibrium phases, specifically martensite alpha double prime ($\alpha''$). Achieving this specific initial microstructure is vital, as it dictates the alloy's mechanical properties and ensures consistency across different specimens.

Understanding the Process Requirements

The Necessity of Repetition

It is critical to understand that a single pass through the furnace is insufficient for these alloys.

Achieving true homogeneity requires a commitment to repeated melting cycles. Without flipping and remelting the ingot multiple times, you risk retaining compositional segregation that will skew subsequent mechanical or corrosion testing results.

The Dependency on Cooling Rate

The benefits of the copper mold are strictly tied to the suction casting process.

Standard gravity casting may not provide the immediate, high-contact heat transfer required to achieve the non-equilibrium martensitic phases. The "suction" ensures the molten metal fills the mold instantly, maximizing contact with the copper walls for immediate heat extraction.

Making the Right Choice for Your Goal

To ensure your Ti-xNb alloy meets biomedical standards, you must prioritize specific aspects of this workflow based on your target outcome:

- If your primary focus is Biocompatibility and Purity: Prioritize the vacuum integrity and inert gas protection of the furnace to eliminate all traces of oxides and volatile gases.

- If your primary focus is Mechanical Consistency: Strictly adhere to a protocol of multiple flipping and remelting cycles (3-5 times) to overcome density differences and eliminate segregation.

- If your primary focus is Microstructural Engineering: Optimize the copper mold suction parameters to maximize cooling rates, ensuring the formation of the critical martensite $\alpha''$ phase.

Success in Ti-xNb fabrication relies on the seamless integration of protective melting environments with rapid, controlled solidification.

Summary Table:

| Process Component | Key Function | Benefit for Ti-xNb Alloys |

|---|---|---|

| Vacuum Arc Furnace | Environment control & high-energy melting | Prevents oxidation and eliminates volatile impurities |

| Multiple Remelting | 3-5 cycles of flipping and melting | Eliminates macro-segregation for chemical homogeneity |

| Copper Mold | High thermal conductivity heat extraction | Enables rapid solidification for fine-grained structures |

| Suction Casting | Instant mold filling and wall contact | Facilitates formation of critical martensite alpha double prime phases |

Elevate Your Biomedical Alloy Production

Precise control over melting and solidification is the difference between a failed prototype and a biocompatible breakthrough. Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum Arc Furnaces, CVD systems, and lab high-temp furnaces—all customizable for your unique material needs.

Whether you are processing reactive Ti-xNb alloys or developing next-generation ceramics, our equipment ensures the chemical purity and microstructural integrity your research demands.

Ready to optimize your lab's high-temperature processes? Contact KINTEK Experts Today

References

- Felype Narciso de Mattos, Conrado Ramos Moreira Afonso. Wear Behavior of Ti-xNb Biomedical Alloys by Ball Cratering. DOI: 10.1590/1980-5373-mr-2023-0494

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Induction Melting Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What is inductive stirring in melting applications? Master Metallurgical Control for Superior Melt Quality

- How does an induction melting furnace ensure process stability? Achieve Precise Atomization with Induction Technology

- What role does a vacuum induction furnace play in melting Fe-C-Mn-Si alloy steels? Ensure Purity & Precision

- What are the safety measures for a Vacuum Induction Melting Furnace? Essential Protocols for Hazard Prevention

- What materials are crucibles in vacuum casting furnaces typically made of? Choose the Right Material for High-Purity Casts

- How does the vacuum environment contribute to metal quality in VIM furnaces? Achieve Superior Purity and Performance

- What is a Vacuum Induction Melting (VIM) furnace and what does it do? Discover Precision Melting for High-Purity Alloys

- How does the alternating current power supply contribute to the induction heater's operation? Unlock Efficient, Contactless Heating