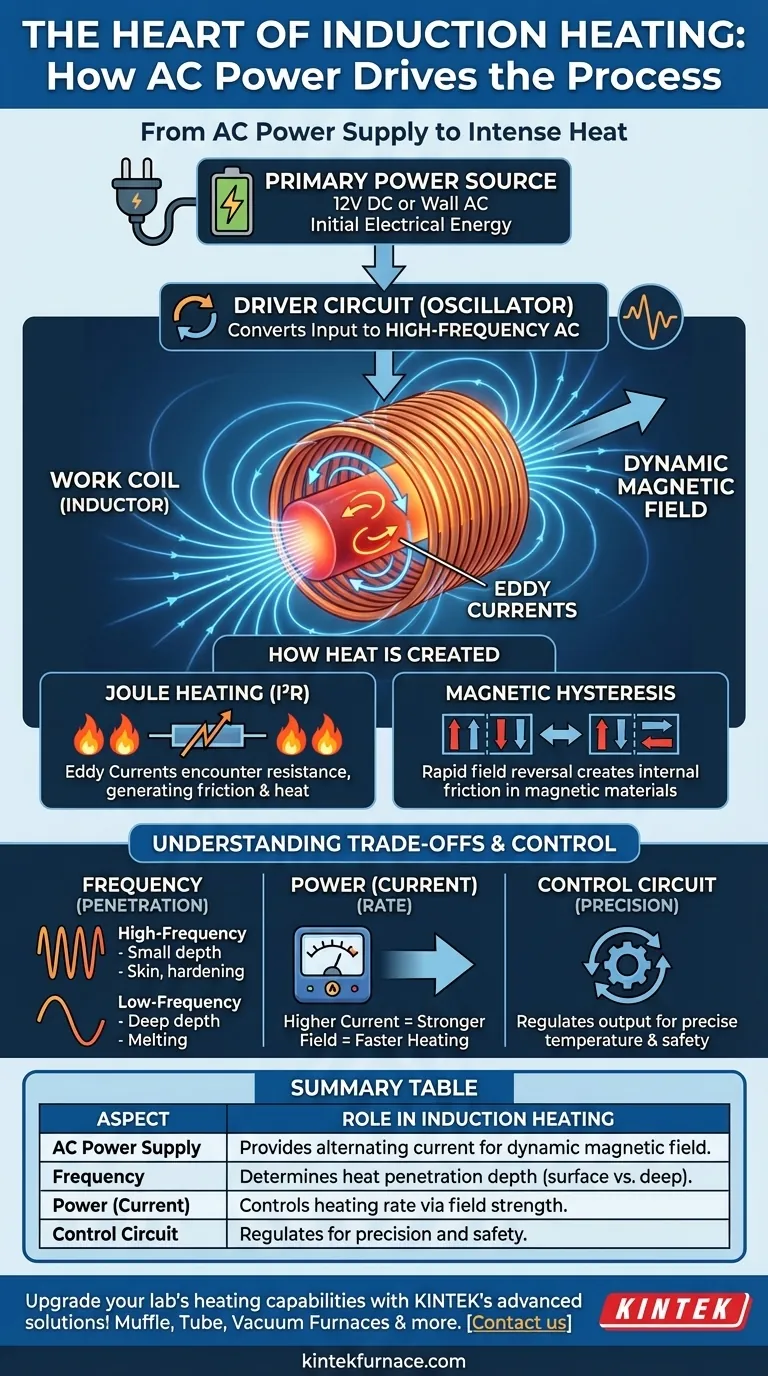

At its core, the alternating current (AC) power supply is the fundamental driver of the entire induction heating process. Its alternating nature is what generates the constantly changing magnetic field in the work coil. Without an alternating current, the magnetic field would be static, and no heating would occur.

The function of the power supply is not merely to provide energy, but to provide the alternating current that an oscillator circuit then uses to create a high-frequency, dynamic magnetic field. This field, not direct electrical contact, is the true source of the induced heat.

From Power Source to Magnetic Field

To understand the system, we must trace the flow of energy from its source to the final effect. The "AC power supply" in an induction heater is often a multi-stage system.

The Initial Energy Source

The process begins with a primary power source, which provides the raw electrical energy. In many DIY or smaller systems, this might be a high-current DC supply, such as a 12V power bank or an AC-to-DC converter plugged into the wall.

The Role of the Driver Circuit

This is the heart of the electronics. A driver or oscillator circuit takes the input power (whether DC or low-frequency AC) and converts it into a high-frequency alternating current. This conversion is the most critical step.

Generating the Dynamic Field

This high-frequency AC is then fed into the work coil. As the current rapidly alternates its direction through the coil, it generates a powerful and rapidly collapsing-and-reversing magnetic field in the space within and around the coil.

How the Magnetic Field Creates Heat

The magic of induction heating lies in the interaction between this dynamic magnetic field and the conductive workpiece.

Inducing Eddy Currents

When a conductive material (like steel or copper) is placed inside the coil, the fluctuating magnetic field induces small, circular flows of electricity within the metal itself. These are known as eddy currents.

The Principle of Resistance (Joule Heating)

All materials, even excellent conductors, have some internal electrical resistance. As the induced eddy currents swirl through the workpiece, they encounter this resistance, creating friction and generating intense heat, a principle known as I²R or Joule heating.

Magnetic Hysteresis Losses

In magnetic materials like iron and steel, there is an additional heating effect. The rapid reversal of the magnetic field forces the magnetic domains within the material to rapidly flip their orientation, creating internal friction and thus more heat.

Understanding the Trade-offs and Control

Simply creating heat is not enough; it must be controlled. The characteristics of the alternating current directly determine the heating effect.

Why Frequency Matters

The frequency of the AC determines how deeply the heat penetrates the material. Higher frequencies (e.g., >100 kHz) cause a "skin effect," concentrating heat on the surface, which is ideal for case hardening. Lower frequencies penetrate deeper, better for melting or through-heating.

The Importance of Power (Current)

The power of the supply, specifically its ability to deliver high current, determines the heating rate. A stronger current in the coil creates a more intense magnetic field, which induces larger eddy currents and heats the workpiece much faster.

The Need for a Control Circuit

A simple power supply and coil are inefficient and dangerous. A control circuit is essential to regulate the frequency and power output, often using feedback from temperature sensors to maintain precise heating profiles and prevent damage to the workpiece or the heater itself.

Making the Right Choice for Your Goal

The design of the power and control system is dictated entirely by the heating task you need to accomplish.

- If your primary focus is rapid surface hardening: You will need a system capable of delivering a high-frequency AC (100 kHz - 400 kHz) to concentrate the heating effect on the skin of the material.

- If your primary focus is melting a large volume of metal: You require a very high-power system operating at a lower frequency (1 kHz - 20 kHz) to ensure deep and thorough energy penetration.

- If your primary focus is precise temperature control for brazing: Your system must prioritize a sophisticated control circuit with feedback sensors over raw power to maintain a stable, specific temperature.

Ultimately, the power supply and its control circuit are not just components; they are the instruments you use to precisely command the invisible force of electromagnetism.

Summary Table:

| Aspect | Role in Induction Heating |

|---|---|

| AC Power Supply | Provides alternating current to generate a dynamic magnetic field in the coil, essential for inducing heat without direct contact. |

| Frequency | Determines heat penetration depth: high frequency for surface heating (e.g., hardening), low frequency for deep heating (e.g., melting). |

| Power (Current) | Controls heating rate: higher current induces stronger magnetic fields and faster heating via larger eddy currents. |

| Control Circuit | Regulates frequency and power, using feedback for precise temperature control and safety in applications like brazing or hardening. |

Upgrade your lab's heating capabilities with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization ensures precise fit for your unique experimental needs, whether for surface hardening, melting, or brazing. Contact us today to discuss how our induction heating technologies can boost your efficiency and results!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Induction Melting Furnace

People Also Ask

- What is the operating temperature of SiC? Unlock Reliable Performance Up to 1600°C

- What heating elements are used in high-temperature tube furnaces? Discover SiC and MoSi2 for Extreme Heat

- What types of heating elements are commonly used in drop tube furnaces? Find the Right Element for Your Temperature Needs

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element

- What parameters does the IEC standard specify for heating elements? Ensure Safety and Performance