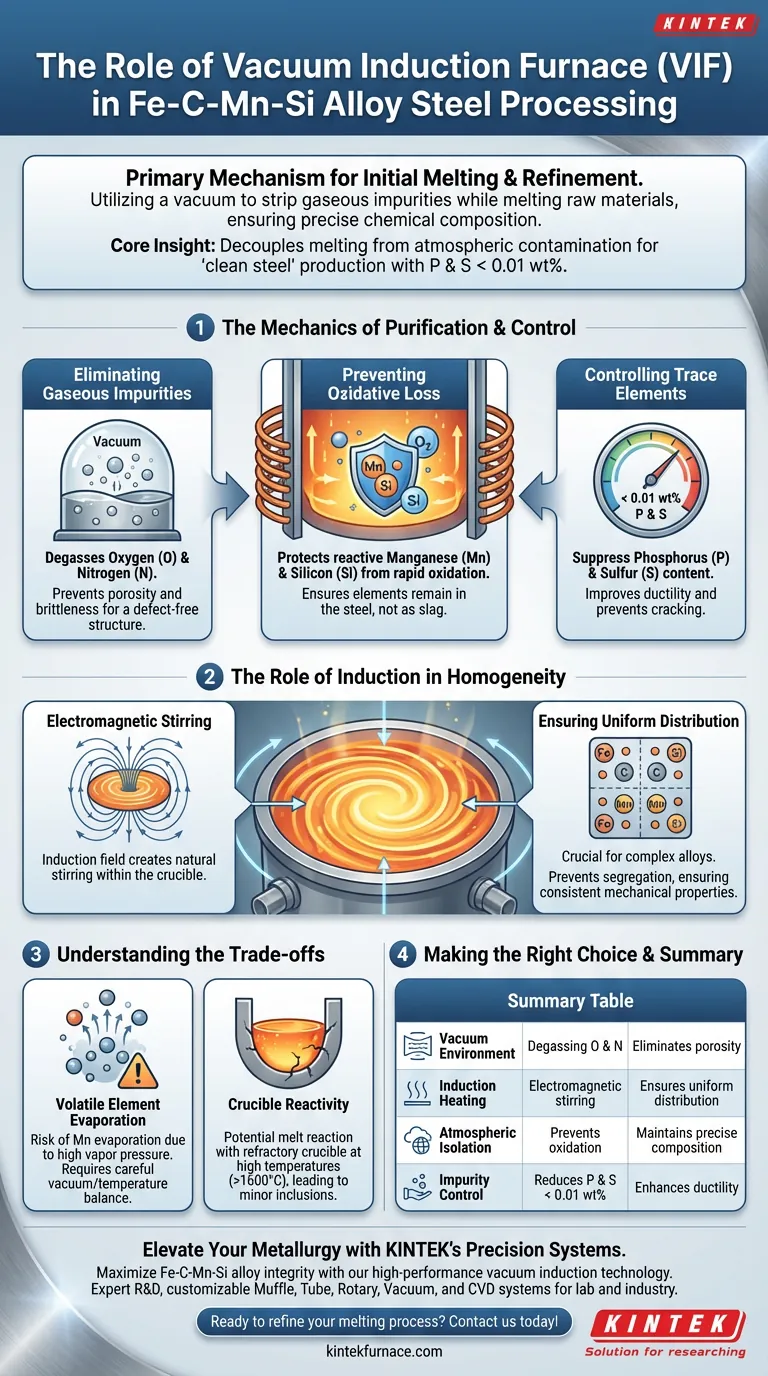

The vacuum induction furnace (VIF) serves as the primary mechanism for the initial melting and refinement of Fe-C-Mn-Si alloy steels. Its function goes beyond simple heating; it utilizes a vacuum environment to actively strip gaseous impurities like oxygen and nitrogen from the molten matrix while melting raw materials into ingots. This controlled isolation prevents the oxidative loss of reactive alloying elements, ensuring the final chemical composition is chemically precise.

Core Insight The true value of a vacuum induction furnace lies in its ability to decouple melting from atmospheric contamination. By maintaining a strict vacuum, it allows for the production of "clean steel" where detrimental impurities like phosphorus and sulfur are reliably kept below 0.01 wt%, a level difficult to achieve with open-air melting.

The Mechanics of Purification and Control

Eliminating Gaseous Impurities

The most critical role of the VIF is the removal of dissolved gases. In a standard melting environment, molten steel absorbs oxygen and nitrogen from the atmosphere, which leads to porosity and brittleness.

The VIF operates under a pressure differential that forces these dissolved gases to precipitate out of the liquid metal. This degassing process is essential for creating a defect-free internal structure in the resulting ingots.

Preventing Oxidative Loss

Fe-C-Mn-Si alloys rely on specific ratios of Manganese (Mn) and Silicon (Si) to achieve their mechanical properties. However, these elements are chemically active and prone to rapid oxidation at high temperatures.

By melting in a vacuum or controlled inert atmosphere, the VIF eliminates the oxygen required for this reaction. This ensures that the alloying elements you add actually remain in the steel, rather than turning into slag or oxide layers.

Controlling Trace Elements

High-performance steels require strict limits on non-metallic inclusions. The VIF environment allows for the precise control of trace elements.

Specifically, the process is capable of suppressing phosphorus and sulfur content to extremely low levels (typically < 0.01 wt%). This reduction is vital for preventing cracking and improving the ductility of the final alloy.

The Role of Induction in Homogeneity

Electromagnetic Stirring

While the vacuum handles purification, the "induction" aspect of the furnace handles mixing. The electromagnetic field used to heat the metal creates a natural stirring effect within the crucible.

Ensuring Uniform Distribution

This stirring action is crucial for complex alloys like Fe-C-Mn-Si. It ensures that the carbon, manganese, and silicon are distributed uniformly throughout the iron matrix.

Without this convection, heavier elements might settle or segregate, leading to inconsistent mechanical properties across the ingot.

Understanding the Trade-offs

Volatile Element Evaporation

While the vacuum removes unwanted gases, it can also cause the evaporation of desirable elements with high vapor pressures. Manganese, a key component of this specific alloy, has a relatively high vapor pressure. Operators must carefully balance vacuum levels and temperature to degas the steel without boiling off the manganese.

Crucible Reactivity

Despite the clean atmosphere, the molten steel is still in contact with a refractory crucible. At the high temperatures required for steel (often exceeding 1600°C), there is a risk of the melt reacting with the crucible material. While less severe than atmospheric contamination, this interaction can introduce minor oxide inclusions if the refractory material is not selected carefully.

Making the Right Choice for Your Goal

When integrating VIF technology into your metallurgy process, consider your specific purity targets:

- If your primary focus is mechanical ductility and toughness: Rely on the VIF to drive phosphorus and sulfur levels below the 0.01 wt% threshold to prevent embrittlement.

- If your primary focus is precise chemical specification: Use the vacuum environment to protect reactive elements like Silicon and Manganese from oxidation, ensuring your input weight matches the final alloy composition.

The vacuum induction furnace effectively transforms the melting process from a chaotic thermal event into a precise chemical reaction, securing the integrity of the alloy from the very first step.

Summary Table:

| Feature | Role in Fe-C-Mn-Si Alloy Processing | Benefit |

|---|---|---|

| Vacuum Environment | Degassing oxygen and nitrogen | Eliminates porosity and internal defects |

| Induction Heating | Electromagnetic stirring of the melt | Ensures uniform distribution of Mn and Si |

| Atmospheric Isolation | Prevention of reactive element oxidation | Maintains precise chemical composition |

| Impurity Control | Reduction of P and S to < 0.01 wt% | Enhances ductility and prevents cracking |

Elevate Your Metallurgy with KINTEK’s Precision Systems

Maximize the integrity of your Fe-C-Mn-Si alloys with KINTEK’s high-performance vacuum induction technology. Backed by expert R&D and world-class manufacturing, we provide customizable Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the rigorous demands of modern lab and industrial applications. Whether you need to achieve ultra-low impurity levels or precise chemical homogeneity, our high-temperature furnaces deliver the control you require.

Ready to refine your melting process? Contact us today to find your custom furnace solution!

Visual Guide

References

- Monika Krugla, Dave N. Hanlon. Microsegregation Influence on Austenite Formation from Ferrite and Cementite in Fe–C–Mn–Si and Fe–C–Si Steels. DOI: 10.3390/met14010092

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the advantages of Vacuum Induction Melting (VIM)? Achieve Unmatched Metal Purity and Performance

- What is the core role of a Vacuum Induction Melting (VIM) furnace in C1023 superalloys? Ensure High-Purity Melts

- How does induction heating compare to resistance furnaces in ammonia decomposition? Experience Dynamic Precision Control

- How do induction furnaces contribute to sustainability in metal casting? Boost Efficiency and Cut Waste

- What is the purpose of the vacuum chamber in an induction-heated vacuum furnace? Achieve Purity and Performance in Materials Processing

- How does vacuum induction melting improve the control of active elements? Achieve Precise Alloy Chemistry with VIM

- What are the benefits of vacuum induction smelting technology? Achieve Superior Purity and Performance for Advanced Materials

- Which is better: induction furnace or electric arc furnace? The right tool for your metallurgical mission.