In an induction-heated vacuum furnace, the vacuum chamber's primary purpose is to create a sealed, low-pressure environment. By evacuating the air, it prevents oxygen and other reactive gases from coming into contact with the heated material, thereby stopping oxidation and contamination during the melting or heating process.

The vacuum chamber is not merely a container; it is an active system for atmospheric control. Its function is to create an ultra-pure environment, which is the fundamental requirement for producing high-quality, high-performance materials with predictable properties.

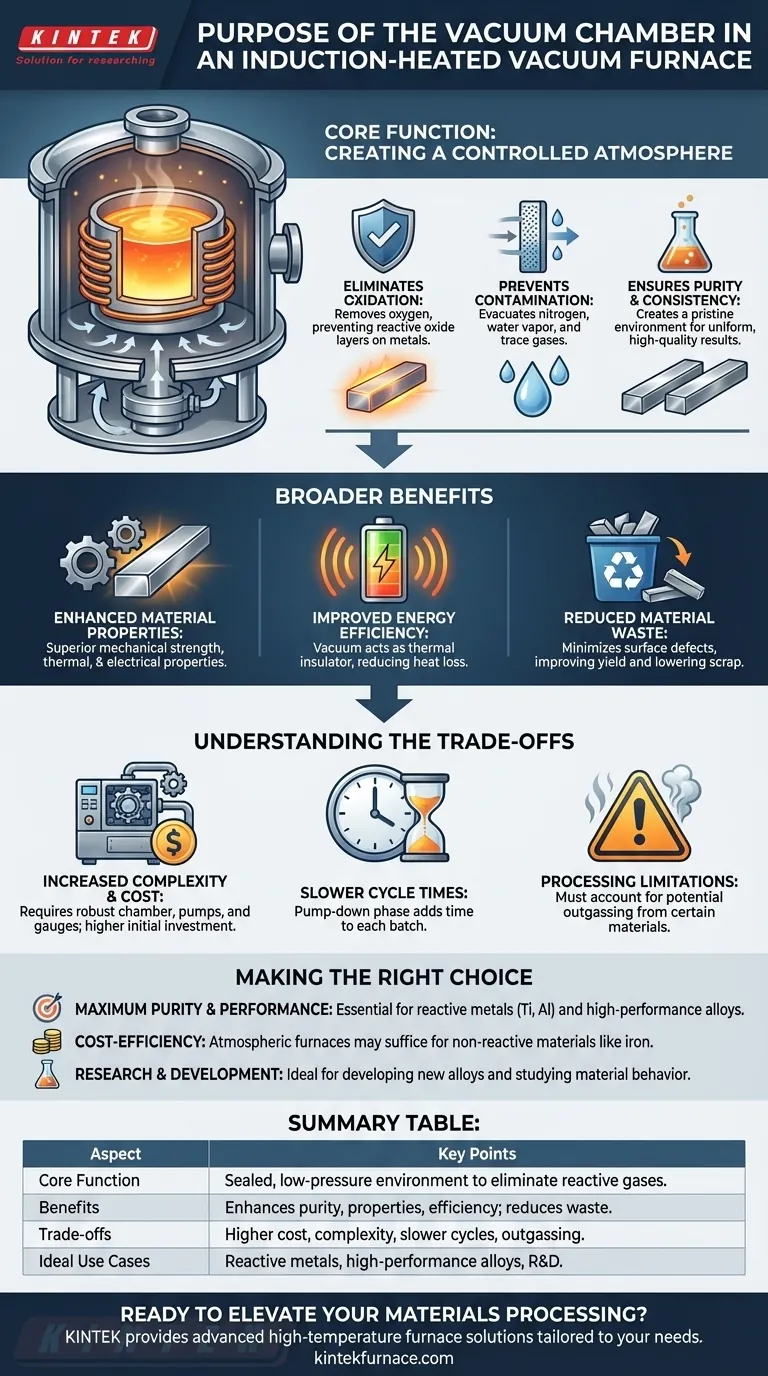

The Core Function: Creating a Controlled Atmosphere

The effectiveness of a vacuum furnace hinges on its ability to isolate the material being processed from the reactive gases present in normal air. The vacuum chamber is the component that makes this isolation possible.

Eliminating Oxidation

When metals are heated to high temperatures, they readily react with oxygen in the air, a process called oxidation. This forms a layer of oxides on the surface, which are essentially impurities that can compromise the final product's integrity and quality. The vacuum chamber allows for the removal of almost all oxygen, preventing this reaction.

Preventing Contamination

Air is not just oxygen; it contains nitrogen, water vapor, and other trace gases. These can also react with hot metals, introducing unwanted contaminants into the material. By creating a vacuum, the chamber removes these potential sources of contamination, ensuring the purity of the melt.

Ensuring Purity and Consistency

By creating a pristine environment free of reactive gases, the chamber ensures that the end product is exceptionally clean and pure. This leads to highly consistent results from one batch to the next, which is critical for industrial production and scientific research.

The Broader Benefits of a Vacuum Environment

Preventing contamination is the direct goal, but achieving it unlocks several significant secondary benefits that enhance the entire process.

Enhancing Material Properties

The absence of impurities and oxides directly results in superior material characteristics. Metals processed in a vacuum often exhibit improved mechanical strength, thermal conductivity, and electrical properties compared to those processed in air.

Improving Energy Efficiency

A vacuum is an excellent thermal insulator. This means that once the material is heated inside the chamber, less heat is lost to the surroundings. This reduction in heat loss makes the entire process more energy-efficient, lowering operational costs.

Reducing Material Waste

For industries like jewelry manufacturing or aerospace, surface finish is critical. Oxidation and other surface reactions create defects that lead to rejected parts and material scrap. The clean environment of a vacuum furnace minimizes these defects, reducing waste and improving yield.

Understanding the Trade-offs

While highly effective, a vacuum environment is not the default choice for all heating applications. It introduces specific considerations that must be weighed against its benefits.

Increased Complexity and Cost

A vacuum furnace is inherently more complex than its atmospheric counterpart. It requires a robust chamber, high-performance seals, and a vacuum system with pumps and gauges. This adds significant initial cost and ongoing maintenance requirements.

Slower Cycle Times

The process of evacuating the chamber to the required vacuum level takes time. This "pump-down" phase adds to the total cycle time for each batch, potentially reducing throughput compared to a simpler furnace.

Processing Limitations

Certain materials can "outgas" at high temperatures in a vacuum, releasing trapped gases that can interfere with the process or contaminate the furnace. This must be accounted for in the process design.

Making the Right Choice for Your Goal

Deciding whether to use a vacuum furnace depends entirely on the requirements of your material and final application.

- If your primary focus is maximum purity and performance: A vacuum furnace is essential for reactive metals (like titanium or aluminum) and high-performance alloys where any contamination degrades critical properties.

- If your primary focus is cost-efficiency for non-reactive materials: A simpler atmospheric furnace may be sufficient for materials like iron or certain steels where a small amount of surface oxidation is acceptable or can be removed later.

- If your primary focus is research and development: A vacuum furnace provides the highly controlled and repeatable environment necessary for developing new alloys and precisely studying material behavior.

Ultimately, investing in a vacuum environment is a strategic decision to control material purity at the atomic level, ensuring the highest possible quality in the final product.

Summary Table:

| Aspect | Key Points |

|---|---|

| Core Function | Creates a sealed, low-pressure environment to eliminate oxygen and reactive gases, preventing oxidation and contamination during heating or melting. |

| Benefits | Enhances material purity, improves mechanical strength, thermal conductivity, and energy efficiency; reduces material waste and ensures consistent results. |

| Trade-offs | Higher initial cost, increased complexity, slower cycle times due to pump-down, and potential outgassing issues with certain materials. |

| Ideal Use Cases | Essential for reactive metals (e.g., titanium), high-performance alloys, R&D, and applications requiring maximum purity and predictable properties. |

Ready to elevate your materials processing with precision and purity? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities. Whether you're in aerospace, jewelry, or research, our vacuum furnaces ensure contamination-free results and superior performance. Contact us today to discuss how we can optimize your processes and deliver reliable, high-quality outcomes!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control