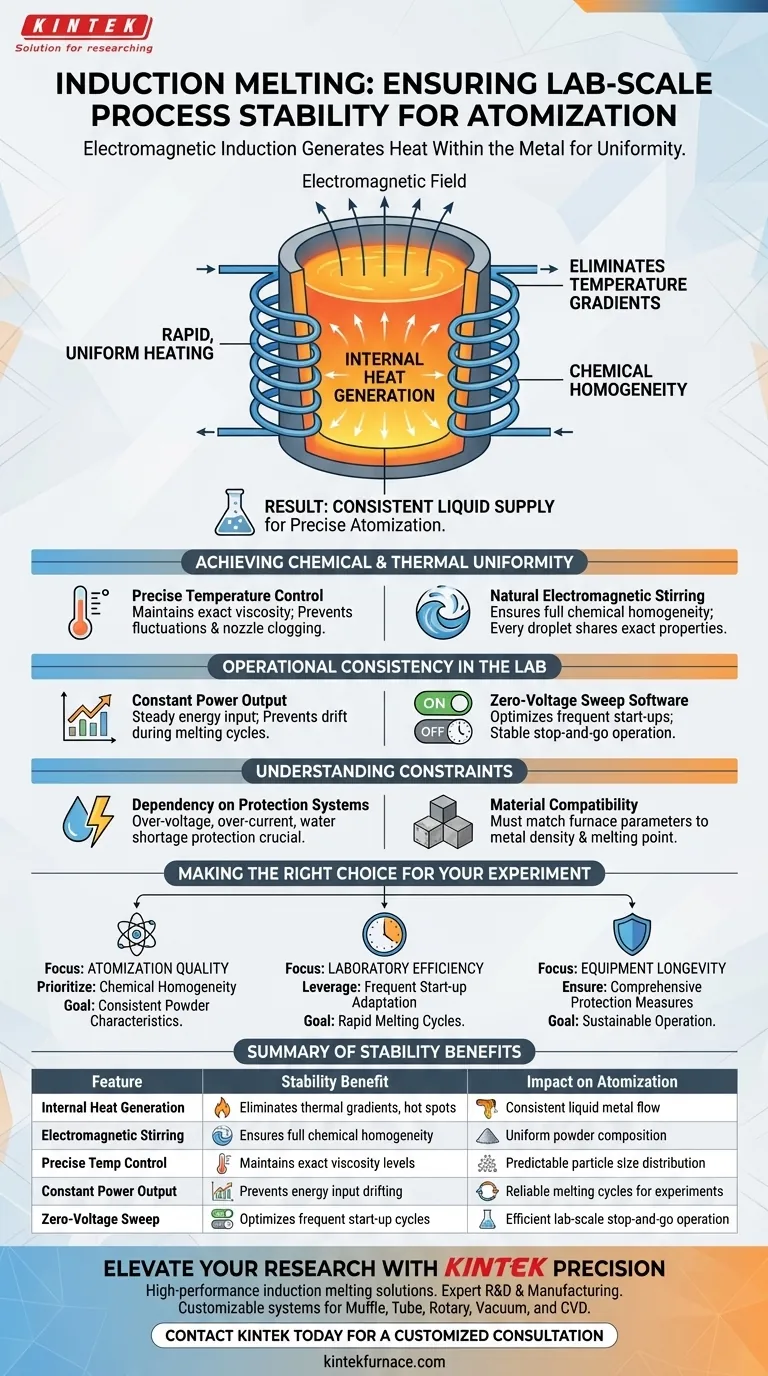

Induction melting guarantees process stability by utilizing electromagnetic induction to generate heat directly within the metal, rather than relying on external heat sources. This method ensures rapid, uniform heating that eliminates temperature gradients and maintains strict chemical homogeneity throughout the melt, which is critical for a consistent liquid supply during atomization.

By decoupling heat generation from external combustion, induction furnaces offer precise temperature control and inherent mixing. This results in a chemically homogeneous melt that ensures the downstream detonation wave atomization process receives a uniform, predictable stream of liquid metal.

Achieving Chemical and Thermal Uniformity

The Mechanism of Uniform Heating

Unlike traditional furnaces that heat a crucible from the outside, an induction furnace uses an electromagnetic field to induce heat within the metal itself. This internal generation of energy allows for rapid melting of metals such as zinc, aluminum alloys, and stainless steel. Because the heat is generated uniformly, it prevents the formation of "hot spots" or cold zones that destabilize the material.

Ensuring Chemical Homogeneity

A critical requirement for atomization is that the composition of the metal remains consistent. The induction process naturally promotes chemical homogeneity within the melt. This ensures that every droplet produced during the detonation wave atomization process shares the exact same chemical properties.

Precise Temperature Control

Stability in atomization relies heavily on viscosity, which is dictated by temperature. Induction furnaces provide precise control over the melting temperature, allowing operators to hold the metal at the exact thermal point required. This prevents fluctuations that could lead to inconsistent particle sizes or nozzle clogging during the atomization phase.

Operational Consistency in the Lab

Constant Power Output

To maintain stability during the melting cycle, modern induction furnaces are designed to deliver a constant power output. This feature not only accelerates the melting speed but also ensures that the energy input remains steady, preventing process variables from drifting during an experiment.

Adaptation for Frequent Start-Ups

Laboratory environments often require stop-and-go operation rather than continuous industrial casting. These furnaces utilize zero-voltage sweep software, which optimizes the equipment for applications requiring frequent start-ups. This ensures the process remains stable and reliable even when cycling through multiple distinct experiments in a single day.

Understanding the Constraints

Dependency on Protection Systems

While induction furnaces offer high stability, they rely heavily on active protection measures to maintain it. The stability of the process is contingent on the proper functioning of over-voltage, over-current, and water shortage protections. If the cooling water supply fluctuates or electrical limits are breached, the system's safety protocols will interrupt the melt to prevent damage, technically halting process stability to preserve safety.

Material Compatibility

While capable of melting a wide range of metals—from precious metals like gold and silver to industrial iron and steel—stability depends on matching the furnace parameters to the specific load. Utilizing the wrong settings for a specific metal density or melting point can compromise the efficiency and consistency of the induction field.

Making the Right Choice for Your Experiment

To ensure your laboratory setup meets your specific research goals, consider the following:

- If your primary focus is Atomization Quality: Prioritize the furnace's ability to maintain chemical homogeneity, as this directly dictates the consistency of your final powder characteristics.

- If your primary focus is Laboratory Efficiency: Leverage the zero-voltage sweep software and constant power output to handle frequent start-ups and rapid melting cycles.

- If your primary focus is Equipment Longevity: Ensure your facility can support the comprehensive protection measures, specifically the water cooling and voltage regulation requirements.

The superior stability of induction melting comes from its ability to turn the metal itself into the heat source, removing variables to create a perfectly predictable feed for atomization.

Summary Table:

| Feature | Stability Benefit | Impact on Atomization |

|---|---|---|

| Internal Heat Generation | Eliminates thermal gradients and hot spots | Consistent liquid metal flow |

| Electromagnetic Stirring | Ensures full chemical homogeneity | Uniform powder composition |

| Precise Temp Control | Maintains exact viscosity levels | Predictable particle size distribution |

| Constant Power Output | Prevents energy input drifting | Reliable melting cycles for experiments |

| Zero-Voltage Sweep | Optimizes frequent start-up cycles | Efficient lab-scale stop-and-go operation |

Elevate Your Metal Research with KINTEK Precision

Consistency is the backbone of successful material science. KINTEK provides high-performance induction melting solutions designed to deliver the chemical and thermal stability required for advanced atomization.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces—all fully customizable to meet your unique experimental needs. Whether you are melting zinc alloys or stainless steel, our technology ensures your process remains stable from start to finish.

Ready to optimize your lab's atomization quality? Contact KINTEK today for a customized consultation.

Visual Guide

References

- С. М. Фролов, T. V. Dudareva. Metal Powder Production by Atomization of Free-Falling Melt Streams Using Pulsed Gaseous Shock and Detonation Waves. DOI: 10.3390/jmmp9010020

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the function of a vacuum induction furnace for 6Mo steel? Precision Melting for Super-Austenitic Alloys

- What are the key advantages of using induction heating in manufacturing? Unlock Speed, Precision & Efficiency

- What is the role of vacuum induction furnaces in aluminum alloy oxidation research? Mastering Melt Environment Control

- How is the high volatility of Samarium managed during vacuum melting? Expert Burn-off Compensation Strategies

- How does an induction heating furnace compare to a resistance heating furnace in the production of ultrafine magnesium powder? Unlock 20X Higher Yield

- What are the overall benefits of medium frequency induction furnaces in industrial applications? Achieve Rapid, Precise, and Clean Heating

- What role does the vacuum chamber play in the melting process? Enhance Metal Purity and Efficiency

- What are the main industrial applications of induction heating? Unlock Precision and Efficiency in Your Processes