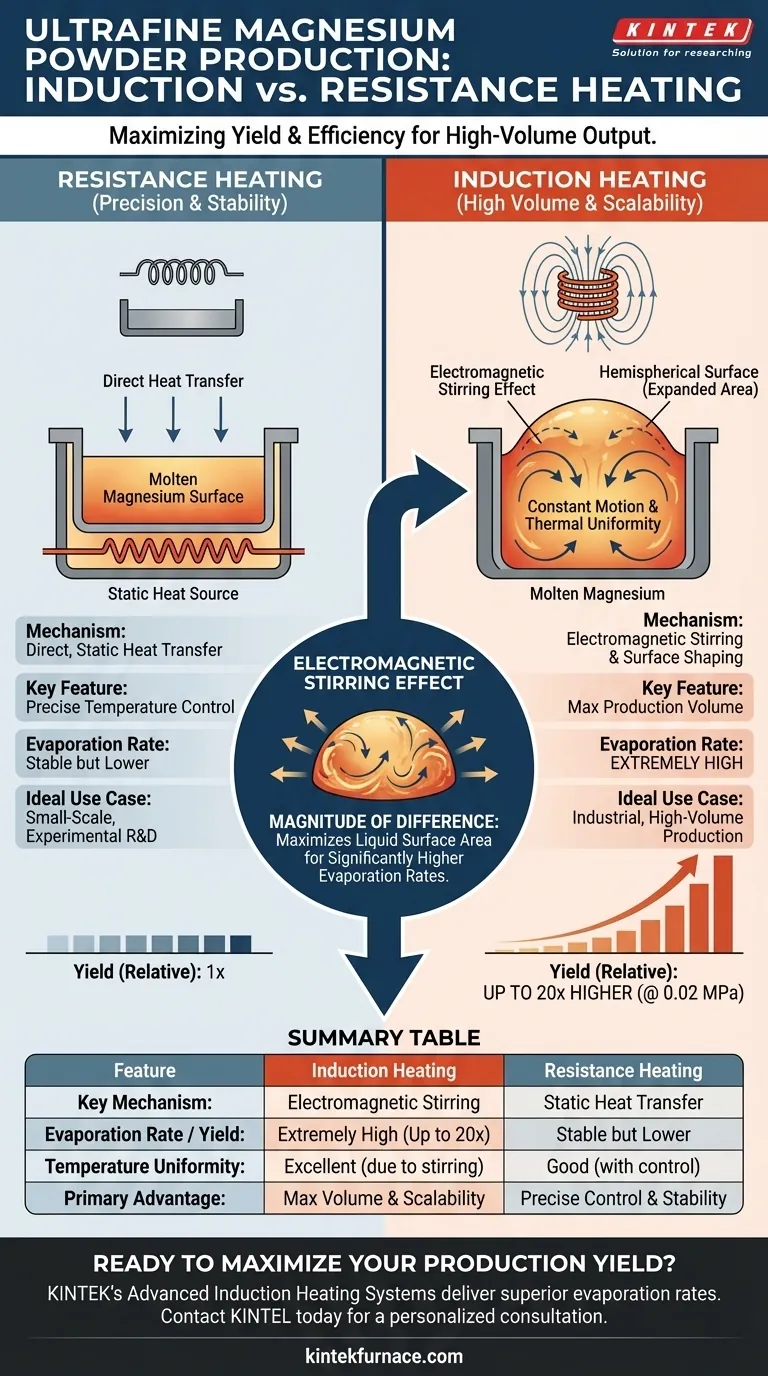

In the production of ultrafine magnesium powder, induction heating offers a vastly superior evaporation rate and overall yield compared to resistance heating. While resistance heating provides stability, induction heating utilizes electromagnetic forces to fundamentally alter the behavior of the molten metal, resulting in yield increases that can exceed 20 times at specific pressures (e.g., 0.02 MPa).

Core Takeaway While resistance heating offers precise temperature control, induction heating is the definitive choice for high-volume production. Its primary advantage is the generation of an electromagnetic stirring effect, which maximizes the liquid surface area and ensures thermal uniformity, driving significantly higher evaporation rates.

The Mechanics of Superior Yield

To understand why induction heating is more efficient for this specific application, you must look beyond simple heat transfer. The difference lies in how the heating method interacts with the physical state of the molten magnesium.

The Role of Electromagnetic Stirring

Resistance heating relies on a static heat source (a resistance wire) to transfer thermal energy.

In contrast, induction heating utilizes an induction coil to generate an alternating magnetic field.

This field induces an electromagnetic stirring effect within the molten magnesium. This constant motion ensures a highly uniform temperature distribution throughout the melt, preventing cold spots that could hamper evaporation.

Optimizing Surface Geometry

The most critical impact of electromagnetic stirring is physical, not just thermal.

The electromagnetic forces shape the liquid magnesium surface into a hemisphere.

This geometric change is vital because it significantly expands the effective evaporation area. A larger surface area directly correlates to a faster evaporation rate, allowing more powder to be produced in less time.

The Magnitude of the Difference

The performance gap between the two technologies is not marginal.

At a pressure of 0.02 MPa, induction heating furnaces have been shown to outperform resistance heating furnaces in yield by a factor of over 20.

For industrial-scale production where throughput is the primary metric, this difference represents a massive efficiency gain.

Operational Trade-offs: Control vs. Volume

While induction heating dominates in raw output, it is important to understand the operational distinction between the two methods to ensure the right fit for your specific process parameters.

Resistance Heating: Prioritizing Precision

Resistance heating evaporation uses a resistance wire as the primary heat source.

The defining characteristic of this method is precise temperature control.

Because the heat generation is linear and direct, it is easier to maintain an exact, static temperature profile. This may be preferable in small-scale experimental setups where thermal stability is more critical than total volume.

Induction Heating: Prioritizing Throughput

Induction heating evaporation is controlled by adjusting the heating frequency and power of the coil.

While this allows for powerful heating, the dynamic nature of the molten metal (due to stirring) introduces more complex variables than a static resistance furnace.

However, the trade-off is heavily skewed in favor of induction for this specific application, as the benefits of surface area expansion far outweigh the simplicity of resistance heating.

Making the Right Choice for Your Goal

The decision between these two furnace types depends entirely on whether your operation values strict thermal precision or maximum production volume.

- If your primary focus is High-Volume Production: Choose the induction heating furnace to leverage electromagnetic stirring and maximize your yield by up to 20 times.

- If your primary focus is Experimental Precision: Choose the resistance heating furnace if your process requires static, highly controlled temperatures over raw evaporation speed.

Ultimately, for the commercial production of ultrafine magnesium powder, induction heating is the industry standard for efficiency and scalability.

Summary Table:

| Feature | Induction Heating Furnace | Resistance Heating Furnace |

|---|---|---|

| Key Mechanism | Electromagnetic stirring & surface shaping | Direct, static heat transfer |

| Evaporation Rate / Yield | Extremely High (Up to 20x higher at 0.02 MPa) | Stable but Lower |

| Temperature Uniformity | Excellent (due to stirring) | Good (with precise control) |

| Primary Advantage | Maximum Production Volume & Scalability | Precise Temperature Control & Stability |

| Ideal Use Case | Industrial, High-Volume Production | Small-Scale, Experimental R&D |

Ready to Maximize Your Ultrafine Powder Production Yield?

For manufacturers focused on scalability and efficiency, the right furnace technology is critical. KINTEK's advanced induction heating systems are engineered to deliver the superior evaporation rates and electromagnetic stirring effects necessary for high-volume output.

Let us help you achieve your production goals. Our experts will work with you to select or customize a furnace solution—whether Induction, Muffle, Tube, Rotary, or Vacuum—that perfectly matches your process requirements.

Contact KINTEL today for a personalized consultation and see how our expertise can transform your production line.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the technical advantages of using a thin-wall with wide slits crucible? Boost Induction Skull Melting Efficiency

- What is a resonant tank circuit and how is it used in the described induction heater? Boost Efficiency with Energy Oscillation

- What is the role of a vacuum arc furnace in Sn-Ag-Cu-Mn-Er solder alloy smelting? Precision Melting for Purity

- What are the applications of IGBT Vacuum Induction Melting Furnaces? Essential for High-Purity Metal Production

- What makes IGBT technology advantageous for induction heating? Achieve Precision, Efficiency, and Speed

- How does the k-epsilon turbulence model with wall functions aid melt flow simulation? Optimize Induction Furnaces

- Importance of Induction Heating System and Coil Design in ODS Steel Bonding: Optimize Your Thermal Profile

- What are the primary advantages of using vacuum melting furnaces? Achieve Superior Purity and Control for High-Performance Materials