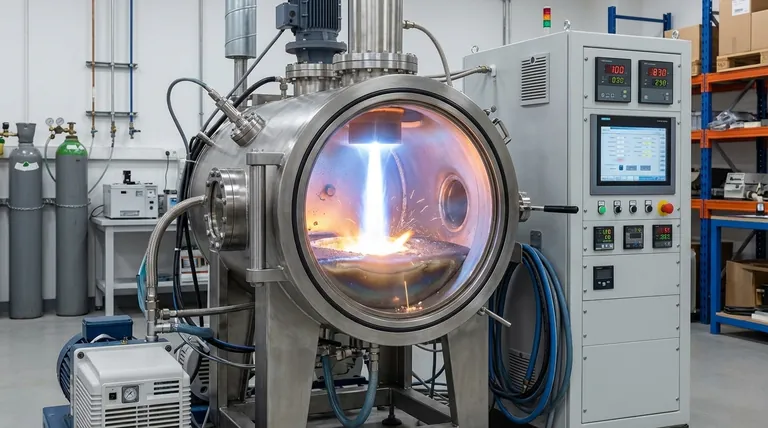

The vacuum arc furnace serves as the definitive tool for synthesizing high-purity Sn-Ag-Cu-Mn-Er solder alloys. Its role is to facilitate the complete melting of constituent metals using high-temperature arc energy while isolating the process from atmospheric contamination. By establishing a vacuum of $5 \times 10^{-1}$ Pa and backfilling with protective gas, the furnace ensures the resulting alloy is free from oxides and chemically uniform.

Core Insight: The inclusion of reactive trace elements like Erbium (Er) and Manganese (Mn) makes standard melting impossible due to rapid oxidation. The vacuum arc furnace is strictly necessary to create a "hermetic" thermal environment, allowing these trace elements to dissolve evenly into the tin matrix without degrading into brittle impurities.

Controlling the Metallurgical Environment

The primary challenge in preparing Sn-Ag-Cu-Mn-Er alloys is managing the reactivity of the components. The vacuum arc furnace addresses this through a precise two-stage environmental control process.

Elimination of Oxygen Interference

The furnace first evacuates the chamber to a high-vacuum state, typically reaching $5 \times 10^{-1}$ Pa.

This step is critical for removing atmospheric oxygen and volatile impurities. Without this deep vacuum, Manganese and Erbium would react immediately with oxygen, forming oxide inclusions that weaken the solder's mechanical properties.

Atmospheric Protection via Argon

Once the vacuum is established, the chamber is backfilled with high-purity argon gas.

This argon atmosphere acts as a protective shield during the actual melting phase. It prevents re-oxidation of the melt pool and stabilizes the arc, allowing for consistent energy transfer to the metal charge.

Achieving Structural Homogeneity

Merely melting metals together is insufficient for experimental solder alloys; the components must be thoroughly mixed to ensure consistent performance.

High-Temperature Arc Energy

The furnace utilizes an electric arc to generate intense, localized heat.

This energy is sufficient to fully melt elements with vastly different melting points, from Tin (low melting point) to Manganese and Erbium (high melting points). Complete fusion of all five elements (Sn, Ag, Cu, Mn, Er) is the baseline requirement for this alloy system.

Distribution of Trace Elements

The most critical role of the furnace is ensuring the uniform distribution of trace elements.

Through repeated melting cycles—where the ingot is melted, flipped, and melted again—the furnace forces the Erbium and Manganese to disperse evenly throughout the Tin-based matrix. This homogeneity is essential for producing valid experimental samples that yield reliable data.

Understanding the Trade-offs

While the vacuum arc furnace is the gold standard for this specific alloy preparation, it is important to recognize the operational constraints.

Volatilization Risks

The high energy of the electric arc can be a double-edged sword.

While necessary to melt Er and Mn, the intense heat can inadvertently vaporize elements with high vapor pressures if not carefully controlled. This mirrors the principles used in vacuum separation processes (like Al-Mg separation), where vacuum and heat drive off volatiles. In solder preparation, however, losing material to evaporation alters the intended composition.

Batch Limitations

Vacuum arc melting is typically a batch process ideal for laboratory-scale or experimental sample preparation.

It is generally not designed for continuous, high-volume mass production. The requirement for repeated melting cycles to ensure uniformity inherently limits throughput speed compared to continuous casting methods.

Making the Right Choice for Your Goal

To maximize the quality of your Sn-Ag-Cu-Mn-Er alloy, consider these operational focuses:

- If your primary focus is Alloy Purity: Prioritize the initial evacuation stage, ensuring the vacuum reaches at least $5 \times 10^{-1}$ Pa to fully degas the chamber before introducing argon.

- If your primary focus is Microstructural Uniformity: Increase the number of melting cycles (flipping the ingot between each) to mechanically force the dispersion of Erbium and Manganese.

Success in preparing this solder alloy depends on balancing the intense energy required to melt rare earths with the strict atmospheric controls needed to preserve them.

Summary Table:

| Feature | Role in Sn-Ag-Cu-Mn-Er Preparation |

|---|---|

| Vacuum Level ($5 \times 10^{-1}$ Pa) | Eliminates oxygen to prevent oxidation of reactive Er and Mn. |

| Argon Backfilling | Stabilizes the electric arc and provides a protective shield during melting. |

| High-Temperature Arc | Provides sufficient energy to fuse elements with disparate melting points. |

| Repeated Melting Cycles | Ensures uniform distribution of trace elements (Er, Mn) throughout the matrix. |

| Atmospheric Control | Prevents brittle oxide inclusions, maintaining superior mechanical properties. |

Elevate Your Materials Synthesis with KINTEK

Precision in solder alloy preparation requires a perfectly controlled metallurgical environment. KINTEK provides industry-leading thermal solutions, including Vacuum, Muffle, Tube, and Rotary systems, specifically designed to handle the complexities of reactive element integration and high-purity smelting.

Backed by expert R&D and manufacturing, our high-temp lab furnaces are fully customizable to meet your unique experimental or production needs, ensuring your Sn-Ag-Cu-Mn-Er alloys achieve maximum homogeneity and performance.

Ready to optimize your alloy preparation?

Contact KINTEK Today to Discuss Your Custom Solution

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance

- What is the role of a vacuum furnace in the solid-phase synthesis of TiC/Cu? Master High-Purity Material Engineering

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- What role do high-power heating plates play in vacuum contact drying furnaces? Unlock Rapid Thermal Diffusion

- Why must sintering equipment maintain a high vacuum for high-entropy carbides? Ensure Phase Purity and Peak Density