At its core, IGBT technology is advantageous for induction heating because it acts as a highly precise and incredibly fast electrical switch. This ability to rapidly control high-power circuits allows modern induction systems to achieve levels of efficiency, speed, and temperature accuracy that were previously unattainable with older technologies.

The central advantage is not simply power, but control. IGBTs enable the creation of high-frequency power supplies that can be adjusted in real-time, ensuring maximum energy is transferred to the workpiece while minimizing waste and improving product quality.

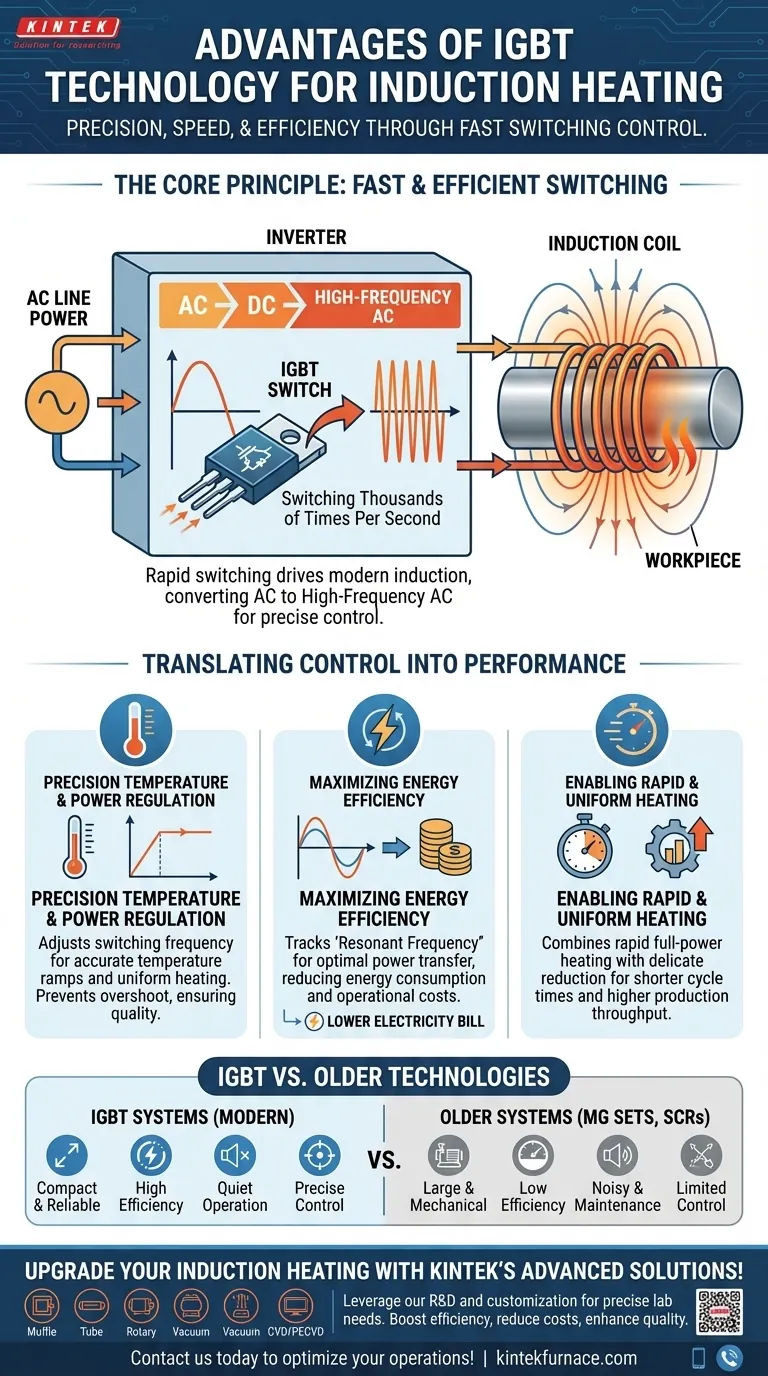

The Core Principle: Fast and Efficient Switching

To understand the advantage, you must first understand the role of the IGBT (Insulated-Gate Bipolar Transistor). It is a powerful semiconductor device that excels at one specific task: turning large amounts of electrical current on and off very quickly.

What an IGBT Actually Does

Think of an IGBT as a heavy-duty light switch with no moving parts. Unlike a mechanical switch, it can be flicked on and off thousands of times per second with extreme reliability and minimal energy loss during the switch itself.

This rapid switching is the engine that drives a modern induction heating power supply, known as an inverter.

From DC to High-Frequency AC

The inverter takes incoming AC line power, converts it to DC, and then uses IGBTs to "chop" that DC power back into a new, high-frequency AC output. This high-frequency current is then sent to the induction coil.

It is this high-frequency alternating magnetic field, generated by the coil, that induces current within the metal workpiece and causes it to heat up.

Why Switching Speed is Everything

The speed and efficiency of the IGBTs are what define the performance of the entire system. Faster switching allows for higher operating frequencies, which provides a wider range of control over the heating process.

Translating Control into Performance

This fundamental capability of rapid, high-power switching directly translates into tangible benefits for industrial applications. The ability to precisely manage the frequency and duty cycle of the power output is what unlocks superior performance.

Precision Temperature and Power Regulation

By adjusting the IGBTs' switching frequency, the system can precisely control the amount of power delivered to the workpiece. This allows for extremely accurate temperature ramps and holds, preventing overshoot and ensuring the material is heated uniformly.

This level of control is critical for meeting stringent quality standards in applications like heat treating, forging, and melting specialty alloys.

Maximizing Energy Efficiency

The highest energy efficiency in an induction system occurs when the output frequency of the power supply matches the natural resonant frequency of the coil and workpiece. As a workpiece heats up, its electrical properties change, which in turn changes this resonant frequency.

Because IGBT-based systems can vary their frequency instantly, they can "track" this moving target, constantly optimizing the power transfer. This ensures that the maximum amount of electrical energy is converted into useful heat, dramatically reducing power consumption and operational costs compared to fixed-frequency systems.

Enabling Rapid and Uniform Heating

The precise power control of an IGBT system allows it to apply full power for rapid heating and then delicately reduce power as the target temperature is approached. This combination of speed and accuracy leads to shorter cycle times and higher production rates.

Furthermore, the localized nature of induction heating is enhanced by this control, ensuring heat is generated only where needed, improving the final quality and integrity of the component.

Understanding the Trade-offs: IGBTs vs. Older Technologies

The advantages of IGBTs are most apparent when compared to the technologies they replaced, such as motor-generator sets or SCR-based power supplies.

The Limitations of Older Systems

Motor-generator (MG) sets were large, mechanical, and inefficient, often converting less than 60% of their input power into useful heat. They also had slow response times and required significant maintenance.

Silicon-Controlled Rectifier (SCR) systems were an improvement, but they operate at lower frequencies and have far less precise control over the power output. They cannot track the resonant frequency of the load, leading to lower efficiency and a less stable process.

The Practical Advantages of IGBT Systems

Beyond pure performance, IGBT power supplies are significantly more compact, reliable, and quieter than their predecessors. Their solid-state design means fewer points of failure and a much smaller footprint on the factory floor.

Making the Right Choice for Your Application

Ultimately, the choice of technology comes down to your primary operational goal. An IGBT-based induction system offers a clear advantage across the three most critical metrics in manufacturing.

- If your primary focus is process quality and consistency: The precise, real-time temperature control of IGBT systems is non-negotiable for producing repeatable, high-quality parts.

- If your primary focus is operational cost reduction: The high energy efficiency gained by tracking the resonant frequency directly translates to significant savings on your electricity bill.

- If your primary focus is production speed and throughput: The ability to combine rapid heating with precise control allows for shorter cycle times, directly increasing your plant's output.

By mastering the flow of energy with unmatched precision, IGBT technology empowers you to achieve a faster, more efficient, and higher-quality heating process.

Summary Table:

| Advantage | Description |

|---|---|

| Precision Control | Enables real-time adjustment of frequency and power for accurate temperature ramps and uniform heating. |

| Energy Efficiency | Tracks resonant frequency to maximize power transfer, reducing energy consumption and operational costs. |

| Rapid Heating | Combines fast switching with precise control for shorter cycle times and higher production throughput. |

| Compact & Reliable | Solid-state design offers smaller footprint, less maintenance, and quieter operation compared to older technologies. |

Upgrade your induction heating with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise alignment with your unique experimental needs. Contact us today to boost efficiency, reduce costs, and enhance quality in your operations!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions