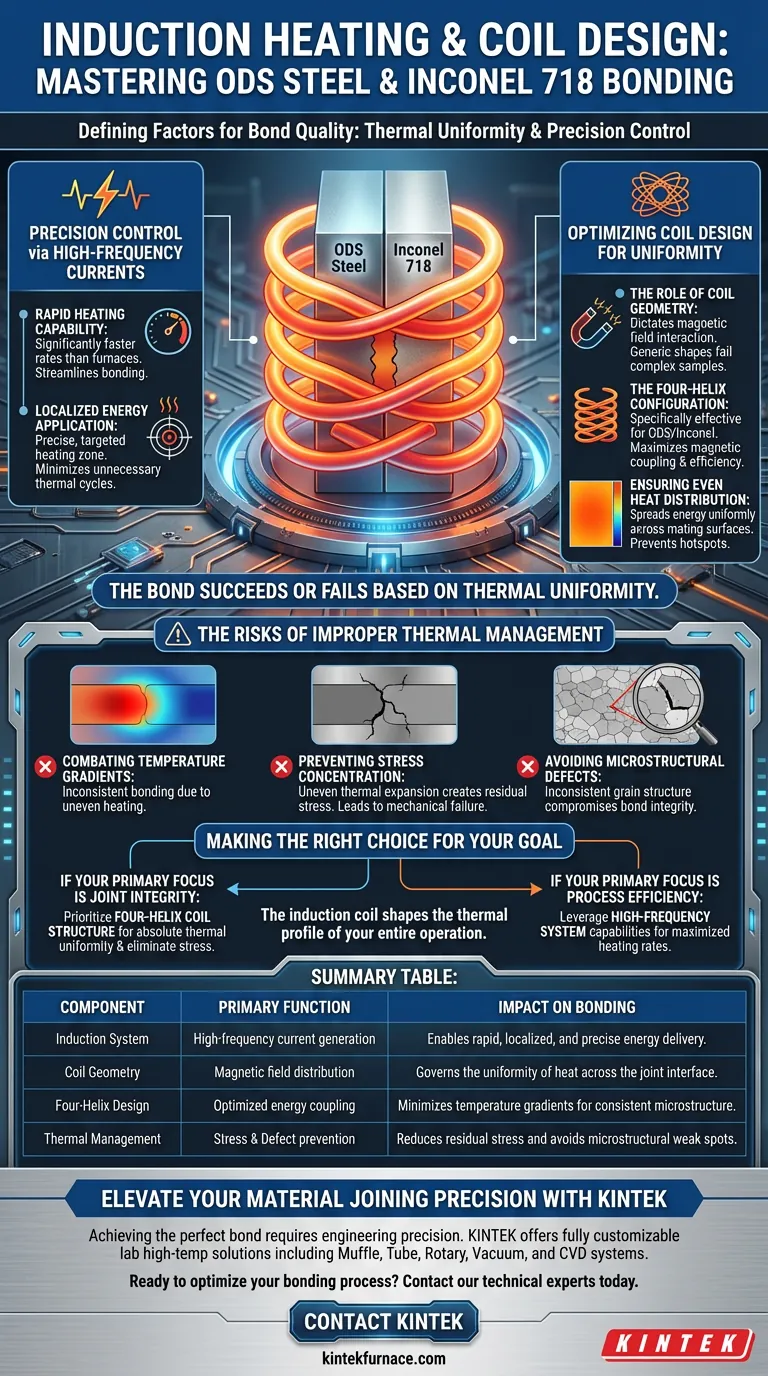

The induction heating system and coil design are the defining factors for the quality of the bond between ODS steel and Inconel 718. The system controls the speed and precision of energy generation through high-frequency currents, while the specific geometry of the induction coil governs the uniformity of heat distribution across the joint interface.

The bond succeeds or fails based on thermal uniformity. While the induction system provides the power for rapid heating, the coil design—specifically a multi-turn structure like a four-helix—is the mechanism that prevents destructive temperature gradients and ensures a homogeneous microstructure at the joint.

Precision Control via High-Frequency Currents

Rapid Heating Capability

The induction heating system utilizes high-frequency currents to generate heat directly within the metal. This mechanism allows for significantly faster heating rates compared to conventional furnace methods, streamlining the bonding process.

Localized Energy Application

Induction heating offers precise, localized control over energy delivery. This allows you to target the bonding zone specifically, rather than subjecting the entire component to unnecessary thermal cycles.

Optimizing Coil Design for Uniformity

The Role of Coil Geometry

The physical design of the induction coil dictates how the magnetic field interacts with the workpiece. A generic coil shape may not provide the even coverage required for complex, sandwich-structured samples.

The Four-Helix Configuration

For bonding ODS steel and Inconel 718, a four-helix coil structure is specifically noted for its effectiveness. This design wraps the joint area to maximize magnetic coupling and energy transfer efficiency.

Ensuring Even Heat Distribution

The primary purpose of this specialized coil design is to distribute heat uniformly throughout the sample. It ensures that energy is not focused on a single point, but is spread evenly across the mating surfaces.

The Risks of Improper Thermal Management

Combating Temperature Gradients

If the coil design is inadequate, the sample will suffer from significant temperature gradients. This means one part of the joint may be overheating while another is barely up to temperature, leading to inconsistent bonding.

Preventing Stress Concentration

Temperature gradients inevitably lead to uneven thermal expansion and contraction. This creates residual stress concentrations at the joint interface, which are a primary cause of immediate or delayed mechanical failure.

Avoiding Microstructural Defects

A properly designed coil prevents microstructural non-uniformity. When heat is applied evenly, the grain structure develops consistently, avoiding weak spots that compromise the integrity of the ODS steel and Inconel 718 bond.

Making the Right Choice for Your Goal

To ensure a robust bond between these advanced materials, align your equipment design with your specific objectives:

- If your primary focus is Joint Integrity: Prioritize a four-helix coil structure to ensure absolute thermal uniformity and eliminate stress concentrations.

- If your primary focus is Process Efficiency: Leverage the high-frequency current capabilities of the system to maximize heating rates without overshooting temperature targets.

The induction coil is not merely a conductor; it is the tool that shapes the thermal profile of your entire operation.

Summary Table:

| Component | Primary Function | Impact on Bonding |

|---|---|---|

| Induction System | High-frequency current generation | Enables rapid, localized, and precise energy delivery. |

| Coil Geometry | Magnetic field distribution | Governs the uniformity of heat across the joint interface. |

| Four-Helix Design | Optimized energy coupling | Minimizes temperature gradients for consistent microstructure. |

| Thermal Management | Stress & Defect prevention | Reduces residual stress and avoids microstructural weak spots. |

Elevate Your Material Joining Precision with KINTEK

Achieving the perfect bond between advanced alloys like ODS steel and Inconel 718 requires more than just heat—it requires engineering precision. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of lab high-temp solutions including Muffle, Tube, Rotary, Vacuum, and CVD systems.

Our equipment is fully customizable to meet your unique induction heating and thermal processing needs, ensuring your lab achieves superior microstructural integrity and process efficiency.

Ready to optimize your bonding process? Contact our technical experts today to find the perfect system for your application.

Visual Guide

References

- José Rodolpho de Oliveira Leo, Michael E. Fitzpatrick. Development of a Diffusion Bonding Route for Joining Oxide-Dispersion-Strengthened (ODS) Steels for Nuclear Applications. DOI: 10.1007/s11661-023-07288-2

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

People Also Ask

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the function of a vacuum induction furnace in FeAl alloy melting? Ensure Purity and Precision

- What is the maximum temperature a Vacuum Induction Melting Furnace can reach? Achieve 2600°C for Pure Metal Melting

- What role does a vacuum induction furnace play in M2 steel refining? Achieve Deep Deoxidation and Purity

- What is the role of shell mold heating in a vacuum induction furnace? Optimize Casting Flow & Integrity

- What materials are typically processed in vacuum melting furnaces? Unlock High-Purity Material Processing

- What are the key advantages of melting metals under vacuum or protective atmospheres? Achieve Purity and Precision in Metal Processing

- What materials and specifications are typically used in vacuum casting? Master High-Fidelity Prototyping with PU Resins