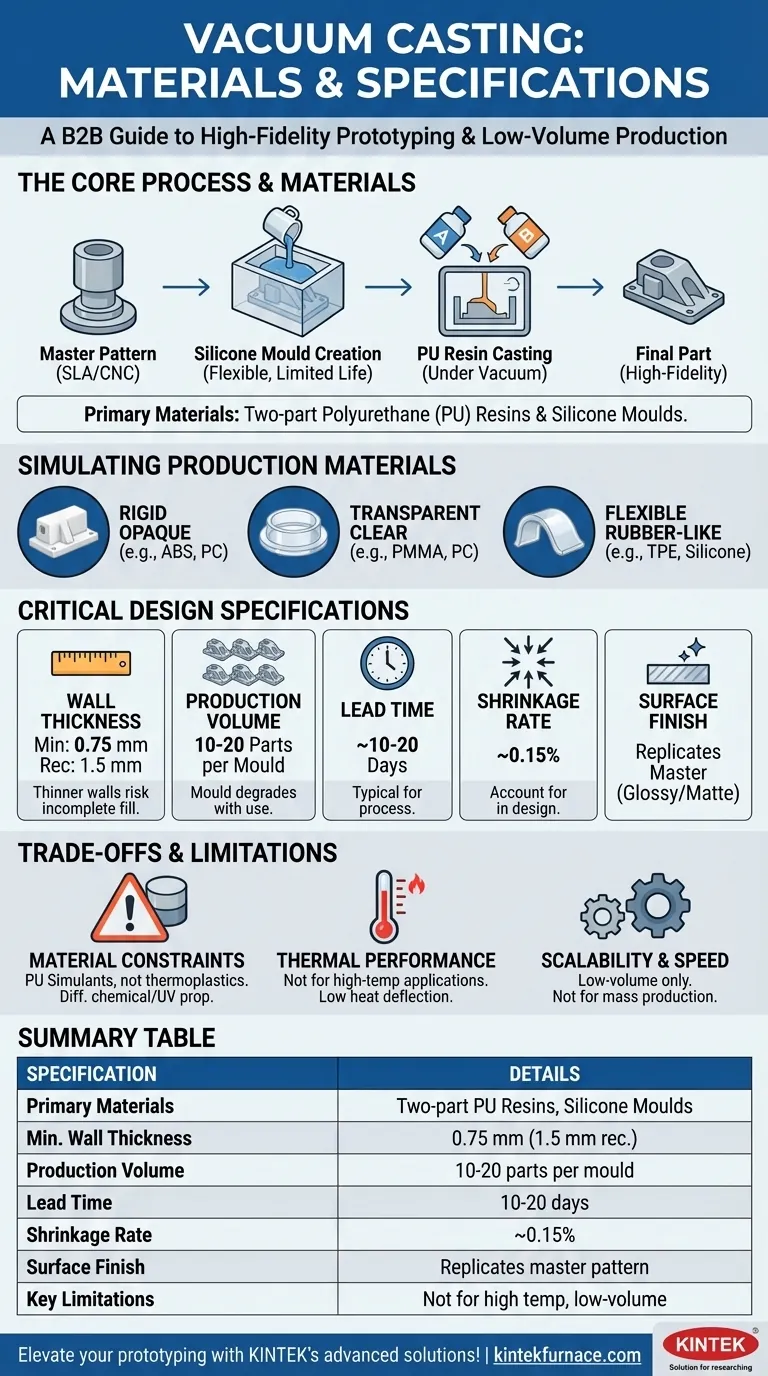

At its core, vacuum casting uses two-part polyurethane (PU) resins to create high-fidelity plastic or rubber-like parts from a silicone mould. Key specifications to keep in mind are a minimum wall thickness of 0.75 mm (with 1.5 mm recommended), a typical production volume of 10-20 parts per mould, and a lead time of around 10-20 days. These parameters define the process's role in manufacturing.

While often seen as a simple prototyping method, vacuum casting's true value lies in its ability to create a small batch of parts that closely mimic the aesthetics and feel of mass-produced goods. Understanding its material and design constraints is the key to leveraging it effectively.

Deconstructing the Materials: More Than Just "Plastic"

The term "vacuum casting materials" primarily refers to the castable polymers, but the silicone used for the mould is an equally important part of the equation.

The Central Role of Polyurethane (PU) Resins

The vast majority of vacuum cast parts are made from two-part polyurethane resins. These liquid polymers are mixed and then poured into the silicone mould under a vacuum to prevent air bubbles.

The versatility of this process comes from the wide variety of available PU resins, which can be formulated with different properties.

Simulating Production-Grade Plastics and Rubbers

Vacuum casting excels at creating parts that mimic the properties of common production materials. You can select resins that are:

- Rigid and opaque, simulating materials like ABS or polycarbonate (PC).

- Transparent and clear, simulating PMMA (acrylic) or clear PC.

- Flexible and rubber-like, simulating elastomers like TPE or even silicone rubber itself, with varying degrees of hardness (shore hardness).

The Silicone Mould as a Material Constraint

The mould itself is made from liquid silicone poured around a master pattern. This silicone mould is flexible, allowing for the creation of complex geometries and undercuts, but it has a limited lifespan. It is also not suitable for high-temperature applications, which restricts the types of castable materials and the final part's thermal resistance.

Critical Design Specifications to Follow

To get a successful result from vacuum casting, your design must adhere to several key specifications driven by the process itself.

Wall Thickness

A minimum wall thickness of 0.75 mm is technically possible, but 1.5 mm is strongly recommended. Thinner walls can prevent the liquid resin from flowing properly and filling the entire mould cavity, leading to incomplete parts.

Part Quantity and Mould Lifespan

A single silicone mould can typically produce between 10 and 20 copies. The exact number depends on the complexity of the part and the abrasiveness of the chosen resin. The mould degrades slightly with each casting cycle, eventually impacting surface finish and dimensional accuracy.

Tolerances and Shrinkage

Parts produced via vacuum casting will experience some shrinkage as the resin cures. A typical shrinkage rate is around 0.15%. This must be accounted for in the design of the master pattern if tight tolerances are a critical requirement for fit and function.

Surface Finish

The surface finish of the final part is a direct replica of the master pattern's finish. The master pattern, often made via high-resolution 3D printing (SLA) or CNC machining, is meticulously sanded and polished. This finish—whether glossy or matte—is transferred to the silicone mould and then to every subsequent part.

Understanding the Trade-offs and Limitations

While powerful, vacuum casting is not a universal solution. Acknowledging its limitations is crucial for project success.

Material Constraints

You are not using actual production thermoplastics like in injection molding. You are using polyurethane simulants. While these can closely match the look, feel, and some mechanical properties, they may not have the same chemical resistance, UV stability, or long-term performance as the real material.

Thermal Performance

Vacuum-cast parts are not suitable for high-temperature applications. The polyurethane resins used generally have a low heat deflection temperature, and the process itself is not designed for high-performance thermal materials.

Scalability and Speed

With a typical lead time of 10-20 days and a low yield per mould, vacuum casting is inherently a low-volume process. It is ideal for prototyping and bridge production but is not cost-effective or fast enough for large-scale manufacturing.

Making the Right Choice for Your Project

Use these guidelines to determine if vacuum casting aligns with your goals.

- If your primary focus is high-fidelity aesthetic prototypes: Vacuum casting is an excellent choice for creating marketing samples, models for photoshoots, or user-testing units that look and feel like the final product.

- If your primary focus is a small batch for form/fit testing: This process is perfect for verifying a design's assembly and ergonomics before investing in expensive mass-production tooling.

- If your primary focus is high-volume production or speed: You should immediately look to other processes like injection molding, as vacuum casting is not designed for scale.

- If your primary focus is high-strength functional parts: Evaluate the mechanical data sheets of available PU resins carefully or consider a more robust process like CNC machining.

By understanding these capabilities and constraints, you can confidently decide when to deploy vacuum casting to achieve your development goals.

Summary Table:

| Specification | Details |

|---|---|

| Primary Materials | Two-part polyurethane (PU) resins, silicone moulds |

| Minimum Wall Thickness | 0.75 mm (1.5 mm recommended) |

| Production Volume | 10-20 parts per mould |

| Lead Time | 10-20 days |

| Shrinkage Rate | ~0.15% |

| Surface Finish | Replicates master pattern (glossy or matte) |

| Key Limitations | Not for high temperatures, low-volume only |

Elevate your prototyping with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, whether for material testing or process development. Ready to enhance your lab's capabilities? Contact us today to discuss how we can support your projects!

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

People Also Ask

- What is a CVD machine? Build High-Performance Materials from Gas with Precision

- How does the availability of specialized furnace systems benefit chemical research? Optimize Your Thermal Processing

- What are the key properties of diamond that make it a promising semiconductor material? Unlock Next-Gen Electronics

- What is a CVD system? Achieve Atomic-Level Precision for High-Performance Coatings

- What is the use of CVD machine? Transform Surfaces with Atomic-Level Precision