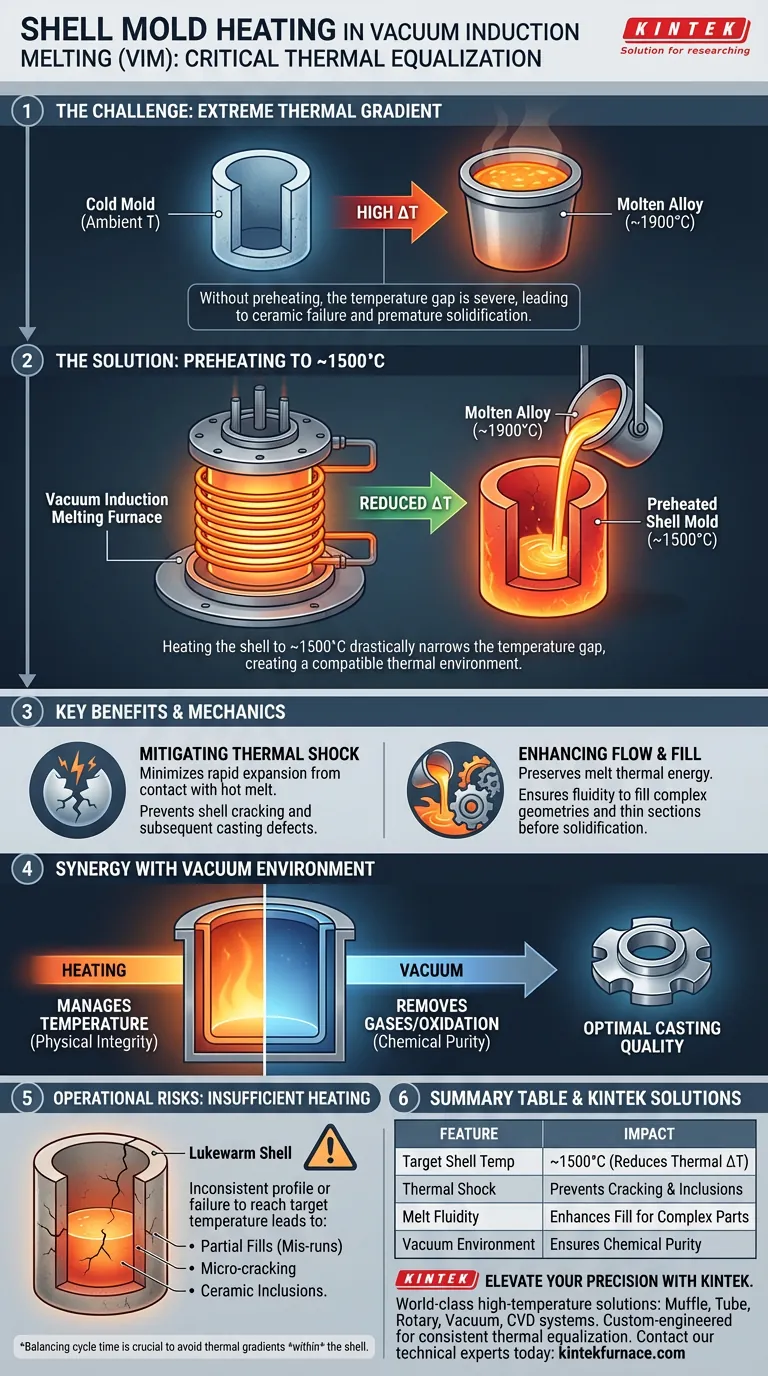

Shell mold heating is the critical thermal equalization step in a vacuum induction melting process. It functions by preheating the ceramic shell to temperatures near 1500 degrees Celsius, drastically reducing the thermal differential between the mold and the incoming 1900-degree Celsius melt.

The core objective of shell mold heating is to synchronize the thermal states of the container and the alloy. By narrowing the temperature gap, you eliminate the risk of ceramic failure due to thermal shock and ensure the molten metal retains the fluidity necessary to fill complex geometries.

The Mechanics of Thermal Compatibility

Reducing the Thermal Gradient

The primary engineering challenge in casting is managing the temperature difference (delta T) between the molten alloy and the mold. Without preheating, the temperature gap is extreme.

Shell mold heating raises the ceramic temperature to approximately 1500 degrees Celsius. This brings the mold significantly closer to the melt temperature of 1900 degrees Celsius, creating a more compatible thermal environment.

Mitigating Thermal Shock

When high-temperature liquid metal contacts a cooler surface, the rapid expansion can cause catastrophic failure.

Preheating the shell minimizes this shock. By ensuring the shell is already in a high-energy thermal state, the system prevents the rapid expansion that leads to shell cracking and subsequent casting defects.

Improving Casting Performance

Enhancing Flow and Fill

A cold mold acts as a heat sink, causing the leading edge of the molten metal to solidify prematurely.

By maintaining a heated shell, the system preserves the thermal energy of the melt during the pour. This improves the filling capability, allowing the metal to flow freely into thin sections and intricate details before solidification begins.

The Role of the Vacuum Environment

While the heater manages temperature, the vacuum furnace system manages chemical purity.

As noted in broader vacuum processing contexts, the vacuum removes air and gases that causes oxidation. Shell mold heating must operate effectively within this low-pressure environment to ensure that the physical improvements in flow are matched by the chemical purity of the final metal structure.

Operational Risks and Considerations

The Consequence of Insufficient Heating

If the heating profile is inconsistent or the target temperature of 1500 degrees Celsius is not reached, the protective benefits evaporate.

A "lukewarm" shell offers little protection against the 1900-degree melt. This often results in partial fills (mis-runs) or micro-cracking in the ceramic that creates positive metal defects on the final part.

Balancing Cycle Time and Temperature

Achieving these high temperatures requires precise energy management.

Operators must balance the time required to thoroughly soak the shell at temperature against the overall cycle time of the vacuum furnace. Rushing this stage introduces thermal gradients within the shell itself, which can be just as damaging as a cold mold.

Making the Right Choice for Your Goal

To maximize the effectiveness of your vacuum induction melting system, align your heating strategy with your specific casting requirements:

- If your primary focus is Structural Integrity: Ensure the shell reaches the target 1500°C to eliminate thermal shock and prevent ceramic inclusions caused by cracking.

- If your primary focus is Geometric Complexity: Prioritize uniform heating to maintain melt fluidity, ensuring the alloy fills the finest details of the mold design.

Effective shell mold heating transforms the ceramic mold from a passive container into an active thermal partner in the casting process.

Summary Table:

| Feature | Impact on Casting Performance |

|---|---|

| Target Shell Temperature | ~1500°C (reduces thermal delta against 1900°C melt) |

| Thermal Shock Mitigation | Prevents ceramic cracking and inclusions in the alloy |

| Melt Fluidity | Enhances filling capability for complex, thin-walled geometries |

| Vacuum Environment | Prevents oxidation and ensures chemical purity of the structure |

Elevate Your Casting Precision with KINTEK

Don't let thermal shock or poor fluidity compromise your high-performance alloys. KINTEK provides world-class laboratory high-temperature solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems, all precision-engineered to meet your most demanding thermal profiles.

Backed by expert R&D and manufacturing, our systems are fully customizable to your unique casting needs, ensuring consistent thermal equalization and superior structural integrity for every part.

Ready to optimize your vacuum melting process? Contact our technical experts today to discover the KINTEK advantage.

Visual Guide

References

- Kilian Sandner, Uwe Glatzel. Investment casting of Cr–Si alloys with liquidus temperatures up to 1900 °C. DOI: 10.1007/s40962-024-01490-7

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Induction Melting Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- What are the advantages and uses of induction furnaces in foundries? Achieve Fast, Clean, and Precise Metal Melting

- What metals and alloys can be cast using induction furnaces? Unlock Precision Melting for All Conductive Metals

- Why is an induction furnace equipped with a graphite susceptor necessary? Achieving Precision for Electrical Steel

- What role does a vacuum induction melting furnace play in the K439B superalloy? Ensure High-Purity Casting Outcomes

- What is inductive stirring in melting applications? Master Metallurgical Control for Superior Melt Quality

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys

- What are the technical advantages of using a Vacuum Induction Levitation Melting Furnace? Achieve Purity and Precision

- How does the control system of an induction melting furnace enhance operation? Boost Efficiency and Precision in Metal Melting