In short, induction furnaces can melt nearly every type of metal. This remarkable versatility is why they are a cornerstone of modern metallurgy, capable of handling everything from common industrial metals like iron, steel, and aluminum to high-value precious metals and specialized aerospace superalloys. The technology's precise control and clean heating method make it suitable for a vast range of applications.

The true value of induction melting isn't just the wide variety of metals it can handle, but its ability to do so with exceptional precision, purity, and efficiency. The choice of an induction furnace is often driven by the need for tight control over the final material's quality and chemistry.

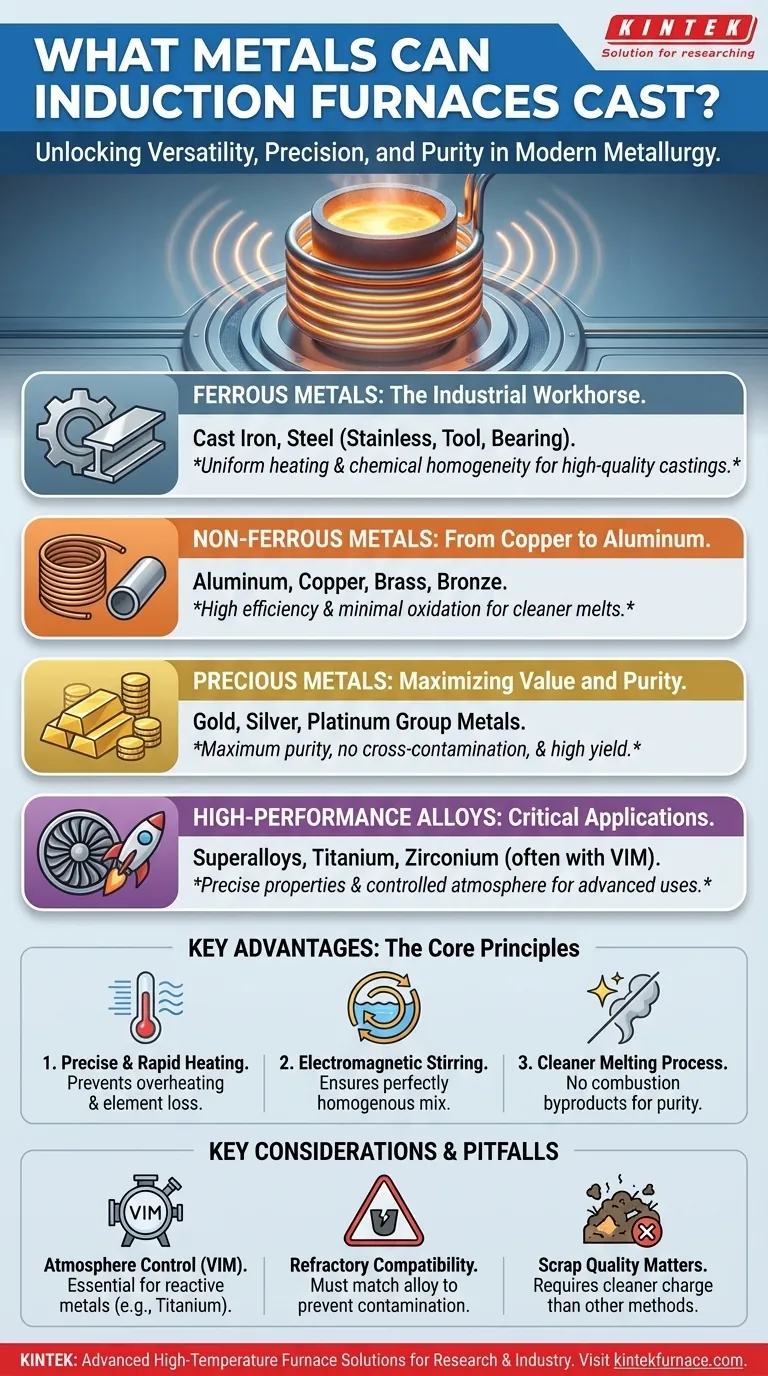

The Spectrum of Compatible Metals

Induction furnaces operate by using a powerful alternating magnetic field to induce an electric current directly within the metal, causing it to heat and melt rapidly from the inside out. This principle is universally applicable to any conductive material, but its advantages are most pronounced with specific metal groups.

Ferrous Metals: The Industrial Workhorse

This is the largest category of materials melted in induction furnaces. It includes all forms of cast iron and a wide variety of steels, such as stainless steel, tool steel, spring steel, and bearing steel.

The rapid melting and electromagnetic stirring inherent to induction create a highly uniform temperature and chemical composition throughout the molten bath, which is critical for producing high-quality steel and iron castings.

Non-Ferrous Metals: From Copper to Aluminum

Induction furnaces are highly effective for melting aluminum, copper, and their respective alloys like bronze and brass.

The high efficiency of the process minimizes the oxidation and loss of valuable metal, a significant advantage over traditional fuel-fired furnaces. This leads to cleaner melts and better yield.

Precious Metals: Maximizing Value and Purity

For high-value materials, induction melting is the preferred method. It is used extensively for gold, silver, and the platinum group metals (platinum, iridium, rhodium, etc.).

Because there is no direct contact with a heating element and the crucible can be emptied completely, cross-contamination is virtually eliminated. This ensures the highest possible purity and minimizes the loss of these expensive materials.

High-Performance and Reactive Alloys

This is where induction technology truly excels. It is essential for producing superalloys (nickel-based or cobalt-based) used in aerospace and power generation, as well as specialty alloys for medical or military applications.

For metals with a high affinity for oxygen and nitrogen, such as titanium, zirconium, and certain stainless steels, a standard induction furnace is used within a controlled environment. This process, known as Vacuum Induction Melting (VIM), places the entire furnace inside a vacuum chamber to prevent atmospheric gases from contaminating the melt, ensuring the material's intended mechanical properties.

Understanding the Key Advantages

The suitability of induction furnaces for such a diverse range of metals stems from a few core principles that deliver tangible benefits in a foundry environment.

Principle 1: Precise and Rapid Heating

The ability to control the power and frequency of the magnetic field gives operators unparalleled control over the melting temperature. This prevents overheating, which can burn off valuable alloying elements and degrade the material's properties.

Principle 2: The Electromagnetic Stirring Effect

The same magnetic field that heats the metal also induces a natural stirring action within the molten bath. This ensures that all alloying elements are distributed evenly, resulting in a perfectly homogenous final product without any chemical segregation.

Principle 3: A Cleaner Melting Process

Since the heat is generated within the metal itself, there are no combustion byproducts (like gas or soot) to contaminate the melt. This intrinsic cleanliness is a primary reason why induction melting is used for applications where purity is non-negotiable, from medical implants to jewelry.

Common Pitfalls and Considerations

While incredibly versatile, induction melting is not a universal solution. Certain considerations and trade-offs must be understood to use the technology effectively.

Atmosphere Control is Not Optional for Reactive Metals

Attempting to melt titanium or certain superalloys in an open-air induction furnace will result in a contaminated, unusable product. For these materials, the investment in a Vacuum Induction Melting (VIM) system is an absolute requirement, adding significant cost and complexity to the operation.

Refractory Lining Compatibility

The crucible, or refractory lining, that holds the molten metal must be chemically compatible with the alloy being melted. Using the wrong type of refractory can cause it to degrade and contaminate the melt, ruining the entire batch. Different metals require different lining materials (e.g., alumina, magnesia, silica).

Scrap Quality Matters

While induction furnaces can melt scrap, they are less forgiving of very dirty, oily, or contaminated charge materials compared to furnaces like the Electric Arc Furnace (EAF). Excessive impurities in the scrap can introduce unwanted elements into the melt that are difficult to remove.

Making the Right Choice for Your Application

Ultimately, the decision to use an induction furnace depends on your material and your goal.

- If your primary focus is high-volume industrial production (iron, steel, aluminum): Induction offers superior efficiency, fast melt rates, and consistent chemical control for reliable, large-scale casting.

- If your primary focus is high-value materials (precious metals, dental alloys): Induction is the ideal choice for maximizing yield, ensuring absolute purity, and preventing the loss of expensive material.

- If your primary focus is performance-critical components (aerospace superalloys, medical titanium): Vacuum Induction Melting (VIM) is the required standard for achieving the pristine metallurgical properties these advanced applications demand.

Understanding how the principles of induction melting align with the properties of different metals empowers you to select the most effective process for your specific goal.

Summary Table:

| Metal Category | Examples | Key Benefits |

|---|---|---|

| Ferrous Metals | Iron, Steel, Stainless Steel | Uniform heating, chemical homogeneity |

| Non-Ferrous Metals | Aluminum, Copper, Brass, Bronze | High efficiency, minimal oxidation |

| Precious Metals | Gold, Silver, Platinum Group | Maximum purity, no cross-contamination |

| High-Performance Alloys | Superalloys, Titanium (with VIM) | Controlled atmosphere, precise properties |

Ready to elevate your metal casting with precision and purity? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for ferrous, non-ferrous, precious, and high-performance alloys. Contact us today to discuss how our induction furnaces can enhance your lab's efficiency and material quality!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How is operator safety ensured during the vacuum induction melting process? Discover Multi-Layered Protection for Your Lab

- What are the advantages of vacuum induction melting? Achieve Superior Purity for High-Performance Alloys

- What are the key components of a Vacuum Induction Melting (VIM) furnace? Master High-Purity Metal Processing

- What industries benefit from Vacuum Induction Melting Furnaces? Unlock High-Purity Metals for Aerospace, Medical, and More

- How does vacuum induction melting work? Achieve Ultra-Pure, High-Performance Alloys