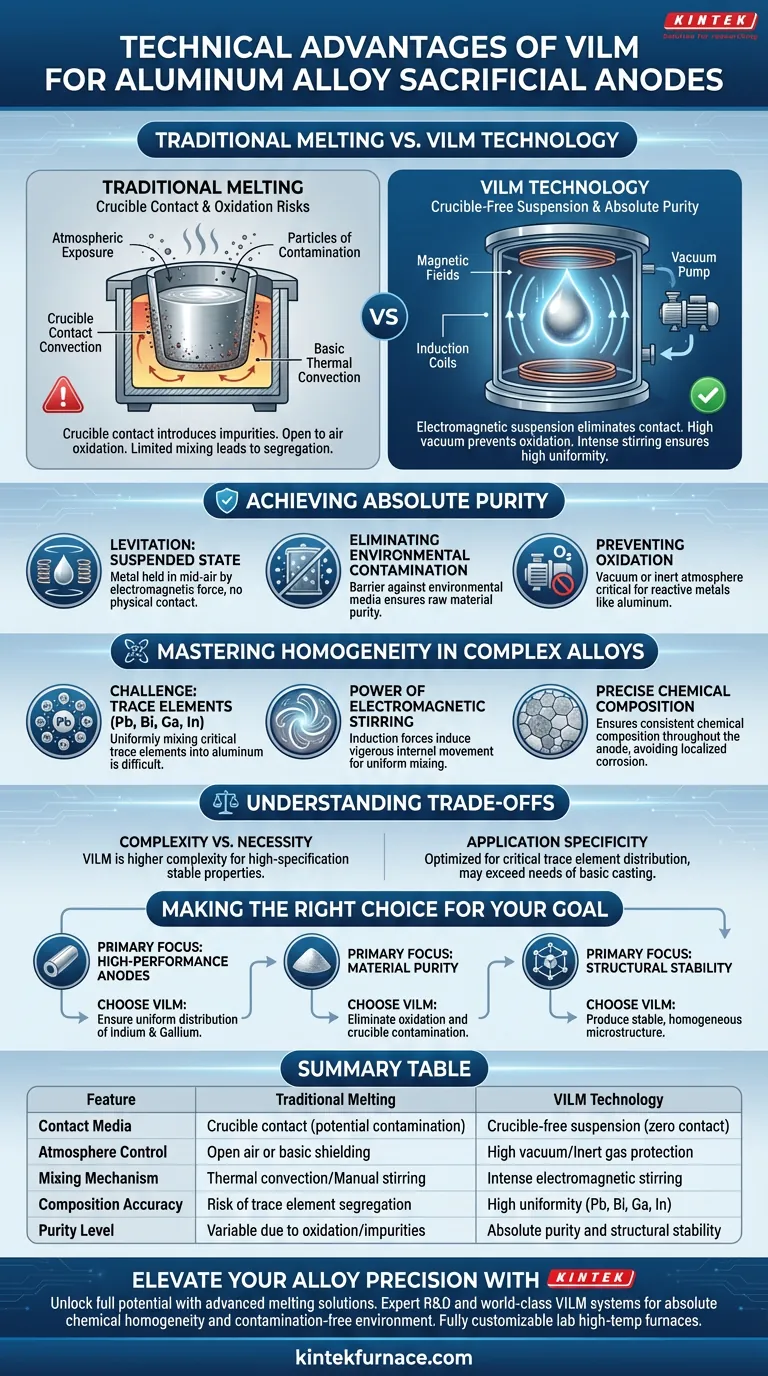

The Vacuum Induction Levitation Melting (VILM) Furnace offers a distinct technical advantage over traditional methods by creating a contamination-free environment and ensuring absolute chemical uniformity. By suspending the metal melt using electromagnetic force, this technology prepares aluminum alloy sacrificial anodes that possess precise chemical compositions and superior structural stability.

The core value of VILM technology lies in its ability to simultaneously isolate the molten metal from physical contaminants and actively homogenize complex alloy elements through electromagnetic stirring, resulting in an anode with predictable and consistent performance.

Achieving Absolute Purity

The Mechanics of Levitation

The defining feature of this furnace is its ability to maintain the metal melt in a suspended state. By utilizing electromagnetic induction force, the system holds the aluminum alloy in mid-air, removing the need for physical contact with container walls that might otherwise degrade the material.

Eliminating Environmental Contamination

Traditional melting often exposes the melt to impurities from the crucible or the surrounding air. The VILM furnace effectively eliminates contamination from environmental media, serving as a barrier that ensures the raw material retains its intended purity levels.

Preventing Oxidation

Building on the principles of standard Vacuum Induction Melting (VIM), the vacuum or inert atmosphere within the furnace acts as an absolute barrier against oxidation. This is critical for reactive metals like aluminum, ensuring the final alloy maintains its integrity without forming weakening oxide inclusions.

Mastering Homogeneity in Complex Alloys

The Challenge of Trace Elements

High-performance sacrificial anodes rely on the precise inclusion of specific trace elements. In aluminum anodes, these typically include Lead (Pb), Bismuth (Bi), Gallium (Ga), and Indium (In). Uniformly mixing these elements into an aluminum matrix is notoriously difficult using static melting methods.

The Power of Electromagnetic Stirring

The VILM furnace solves the mixing challenge through electromagnetic stirring. The same induction forces that heat and levitate the metal also induce vigorous internal movement within the melt.

Precise Chemical Composition

This continuous stirring ensures that the heavy and distinct elements (Pb, Bi, Ga, In) are mixed with high uniformity. Consequently, the final anode has a precise chemical composition throughout its volume, rather than having pockets of unmixed elements that could lead to localized corrosion or failure.

Understanding the Trade-offs

Complexity vs. Necessity

While VILM offers superior results, it introduces higher technical complexity compared to standard furnaces. It is a specialized tool designed for applications where structural properties must be stable and composition must be exact.

Application Specificity

This technology is optimized for high-specification alloys. For basic casting where trace element distribution is not critical to performance, the advanced capabilities of levitation and vacuum processing may exceed the requirements of the project.

Making the Right Choice for Your Goal

To determine if a Vacuum Induction Levitation Melting Furnace is the right investment for your production line, consider your performance requirements:

- If your primary focus is High-Performance Anodes: Choose VILM to ensure the uniform distribution of critical elements like Indium and Gallium for consistent electrochemical performance.

- If your primary focus is Material Purity: Select this technology to eliminate oxidation and contamination from environmental media or crucible contact.

- If your primary focus is Structural Stability: Rely on the electromagnetic stirring inherent in VILM to produce an alloy with a stable, homogeneous microstructure.

Ultimately, VILM is the definitive choice when the precise integration of trace elements defines the success of your aluminum alloy anode.

Summary Table:

| Feature | Traditional Melting | VILM Technology |

|---|---|---|

| Contact Media | Crucible contact (potential contamination) | Crucible-free suspension (zero contact) |

| Atmosphere Control | Open air or basic shielding | High vacuum/Inert gas protection |

| Mixing Mechanism | Thermal convection/Manual stirring | Intense electromagnetic stirring |

| Composition Accuracy | Risk of trace element segregation | High uniformity (Pb, Bi, Ga, In) |

| Purity Level | Variable due to oxidation/impurities | Absolute purity and structural stability |

Elevate Your Alloy Precision with KINTEK

Unlock the full potential of high-performance aluminum sacrificial anodes with KINTEK’s advanced melting solutions. Backed by expert R&D and world-class manufacturing, we provide specialized Vacuum Induction Levitation Melting (VILM) systems alongside our wide range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you require absolute chemical homogeneity or a contamination-free environment, our lab high-temp furnaces are fully customizable to meet your unique materials science needs.

Ready to optimize your production for superior structural stability?

Visual Guide

References

- Xin Liu, Nian Liu. Effect of Bi on the Performance of Al-Ga-In Sacrificial Anodes. DOI: 10.3390/ma17040811

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- How does an induction furnace improve energy efficiency in gold melting? Achieve Faster, Purer Melts

- How is brazing performed using induction heating? Achieve Fast, Precise Metal Joining

- What is the working principle of a medium frequency induction furnace? Achieve Rapid, Precise Metal Melting

- What role does a high-frequency induction furnace play in the melting process of blast furnace slag? Expert Insights

- How do IGBT induction melting furnaces improve precision in material production? Achieve Superior Metallurgical Control

- How does the vacuum environment contribute to metal quality in VIM furnaces? Achieve Superior Purity and Performance

- What environmental benefits do induction furnaces provide? Achieve Cleaner, Safer Industrial Heating

- How does a vacuum induction melting furnace (VIM furnace) work? Achieve Ultra-Pure Metals with Precision Melting