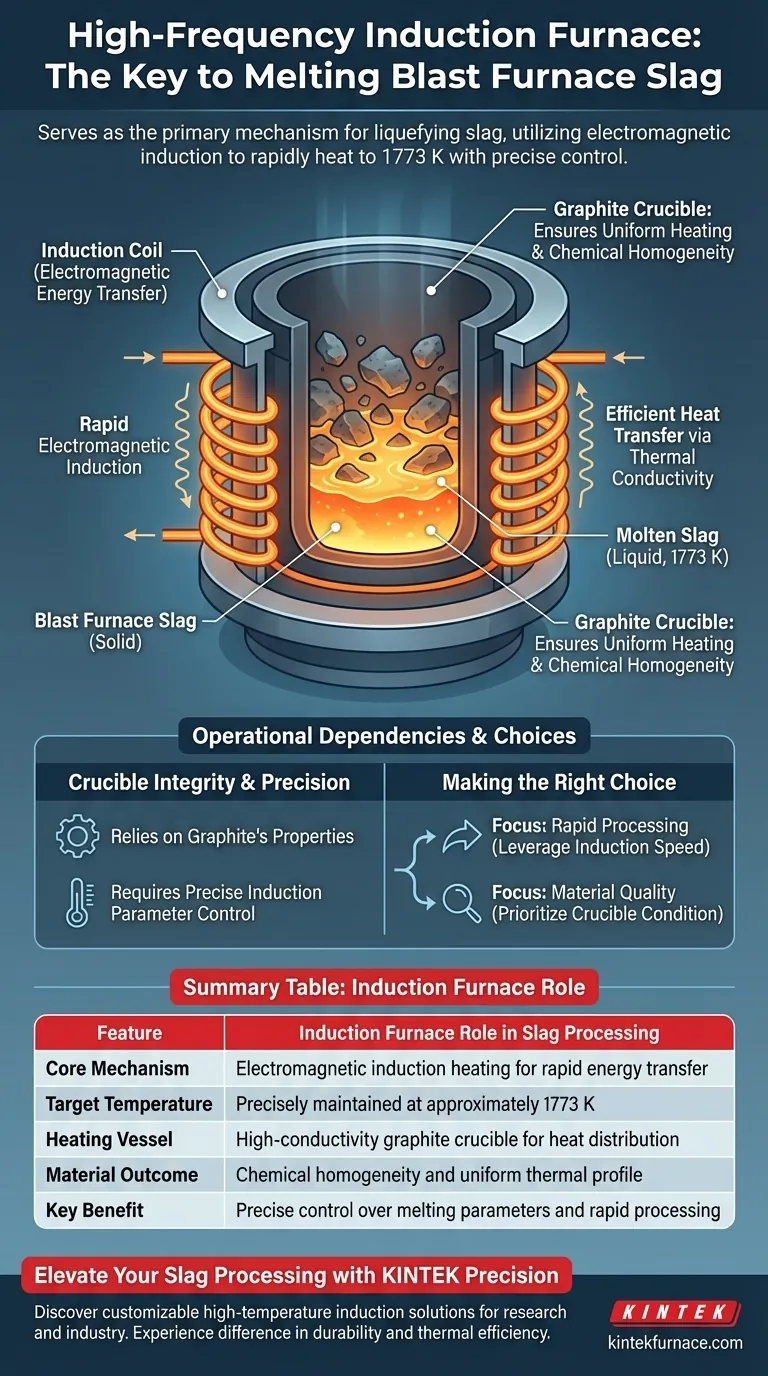

A high-frequency induction furnace serves as the primary mechanism for liquefying blast furnace slag. It utilizes electromagnetic induction to rapidly heat the material to extreme temperatures, specifically targeting states around 1773 K. By containing the slag within a graphite crucible, the furnace ensures the heat is distributed evenly, resulting in precise temperature control and chemical uniformity.

The induction furnace provides a controlled, high-energy environment essential for melting slag, leveraging electromagnetic principles and the thermal properties of graphite to ensure rapid processing and material consistency.

The Mechanics of Induction Heating

Electromagnetic Energy Transfer

The core function of the furnace is to generate heat using electromagnetic induction principles. rather than direct flame or contact heating. This allows energy to be transferred rapidly into the heating vessel.

Reaching High-Temperature States

Blast furnace slag requires significant energy to transition from solid to liquid. The high-frequency induction furnace effectively drives the temperature up to 1773 K. This high thermal ceiling ensures the slag reaches a fully molten state for processing.

The Critical Role of the Graphite Crucible

Leveraging Thermal Conductivity

The slag is held inside a graphite crucible during the melting process. The furnace relies heavily on the graphite's excellent thermal conductivity to act as the medium for heat transfer.

Ensuring Uniform Heating

Because the graphite crucible distributes heat so efficiently, the slag experiences uniform heating throughout the vessel. This prevents localized hot spots or cold zones that could result in uneven melting.

Promoting Chemical Homogeneity

The uniformity of the heating process directly impacts the quality of the molten slag. A consistent temperature profile ensures chemical component uniformity, creating a homogeneous melt that is easier to analyze or process further.

Understanding Operational Dependencies

Reliance on Crucible Integrity

The efficiency of this specific melting process is inextricably linked to the quality of the graphite crucible. The system relies on the specific thermal properties of graphite to moderate the intense energy of the induction field; without it, temperature control would be compromised.

The Necessity of Precision

This is not a passive heating method; it is designed for precise temperature control. While this allows for exacting standards, it requires the operator to manage the induction parameters carefully to maintain the target temperature of 1773 K without overshooting.

Making the Right Choice for Your Goal

When utilizing a high-frequency induction furnace for slag treatment, your operational focus dictates your approach.

- If your primary focus is rapid processing: Leverage the electromagnetic induction capabilities to minimize the time required to reach the target temperature of 1773 K.

- If your primary focus is material quality: Prioritize the condition of the graphite crucible to ensure maximum thermal conductivity and chemical uniformity in the final melt.

The synergy between high-frequency induction and graphite containment offers the most reliable path to obtaining a consistent, high-temperature slag melt.

Summary Table:

| Feature | Induction Furnace Role in Slag Processing |

|---|---|

| Core Mechanism | Electromagnetic induction heating for rapid energy transfer |

| Target Temperature | Precisely maintained at approximately 1773 K |

| Heating Vessel | High-conductivity graphite crucible for heat distribution |

| Material Outcome | Chemical homogeneity and uniform thermal profile |

| Key Benefit | Precise control over melting parameters and rapid processing |

Elevate Your Slag Processing with KINTEK Precision

Are you looking to optimize your material processing or high-temperature laboratory research? Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized high-temperature induction solutions.

Our furnaces are fully customizable to meet your unique operational needs—whether you require extreme temperature precision or chemical uniformity for complex slag analysis. Experience the KINTEK difference in durability and thermal efficiency.

Contact our technical experts today to find your custom solution!

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What role does a vacuum arc melting furnace play in Ti-6Al-7Nb-xTa alloys? Precision Melting & Purity

- What are the main applications of vacuum induction melting (VIM) furnaces? Achieve Unmatched Metal Purity for Critical Industries

- What role does a vacuum induction melting furnace play in the modification of W18Cr4V steel? Enhance Alloy Purity

- What is induction shrink-fitting and how does it work? Master Precision Assembly with Induction Heating

- How does an induction furnace affect copper grain size? Optimize Microstructure with Rapid Heating

- What is the role of a Vacuum Induction Melting (VIM) furnace in superalloys? Secure Purity and Chemical Precision

- What are the advantages of an Induction Cold Crucible Furnace (ICCF) for Nb-MASC? Achieve Ultimate High-Purity Melting

- What is the primary role of a vacuum melting furnace in the production of aluminum-lithium alloys? Achieve High Purity