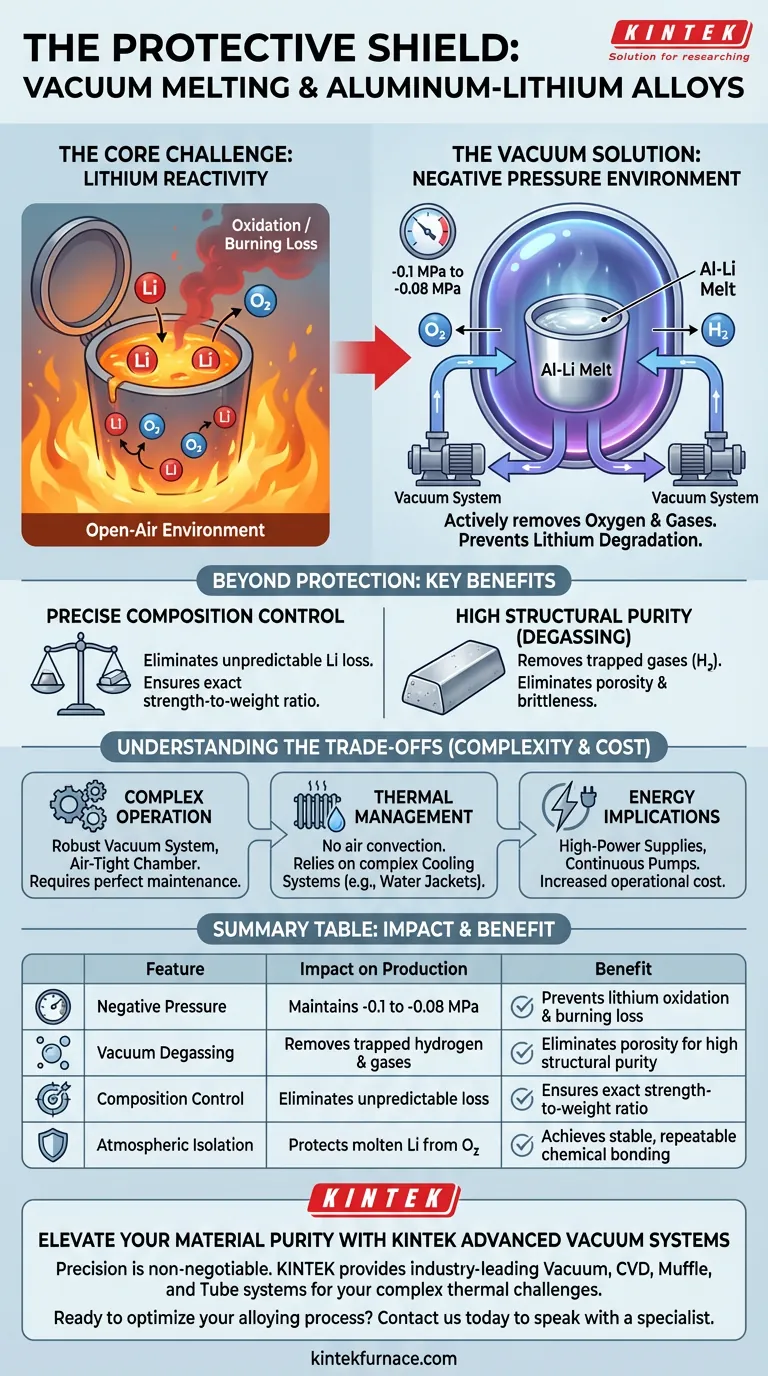

The primary role of a vacuum melting furnace in the production of aluminum-lithium alloys is to act as a protective shield against chemical degradation. It creates a specific negative pressure environment—typically between -0.1 MPa and -0.08 MPa—to prevent the highly reactive lithium element from oxidizing or burning away during the melting process.

Core Takeaway Processing aluminum-lithium alloys requires a delicate balance between high heat and chemical stability. The vacuum melting furnace solves the critical issue of lithium loss, ensuring the final alloy retains its precise intended composition and achieves high structural purity by eliminating trapped gases.

The Critical Challenge of Aluminum-Lithium

The Reactivity Problem

Lithium is an exceptionally reactive element, particularly when exposed to high temperatures. In a standard open-air environment, molten lithium would react instantly with oxygen.

This reaction leads to significant "burning loss," where the lithium content is consumed rather than integrating into the alloy. This makes it impossible to achieve a stable chemical composition without a controlled atmosphere.

The Vacuum Solution

The vacuum melting furnace addresses this by evacuating air to create a negative pressure environment.

By maintaining pressure between -0.1 MPa and -0.08 MPa, the furnace removes the oxygen that would otherwise fuel the oxidation of lithium. This allows the aluminum and lithium to bond effectively without the lithium degrading.

Beyond Protection: Enhancing Alloy Quality

Precise Composition Control

The value of an aluminum-lithium alloy lies in its specific strength-to-weight ratio, which depends entirely on the exact percentage of lithium.

Because the vacuum environment prevents burning loss, manufacturers can predict and control the final chemical composition with high precision. There is no need to "over-dope" the mixture to compensate for unpredictable losses.

Reducing Gas Adsorption

Molten aluminum is prone to absorbing hydrogen and other gases from the atmosphere, which creates porosity (bubbles) in the solidified metal.

The vacuum environment actively degasses the melt. By lowering the pressure, the solubility of gases in the liquid metal decreases, causing trapped gases to escape. This results in an alloy with high purity and superior mechanical integrity.

Understanding the Trade-offs

Complexity of Operation

While essential for quality, vacuum melting adds layers of complexity compared to standard smelting. The system requires a robust Vacuum System (pumps, valves, piping) that must be perfectly maintained. Any leak in the airtight chamber immediately compromises the batch.

Thermal Management Requirements

Operating in a vacuum removes the ability for heat to dissipate via air convection. Therefore, these furnaces rely heavily on complex Cooling Systems, such as water-cooled jackets, to regulate the furnace body temperature and prevent overheating of the equipment itself.

Energy and Cost Implications

The process involves running high-powered Medium Frequency Power Supplies and continuous vacuum pumps. This significantly increases the energy consumption and operational cost per kilogram of alloy produced compared to non-vacuum methods.

Making the Right Choice for Your Goal

To maximize the benefits of vacuum melting for your specific project, consider these priorities:

- If your primary focus is Chemical Precision: Prioritize maintaining a consistent vacuum level between -0.1 MPa and -0.08 MPa to ensure the lithium content remains stable and predictable.

- If your primary focus is Mechanical Performance: Focus on the degassing phase of the vacuum cycle to ensure all adsorbed gases are removed, preventing porosity and brittleness.

Success in producing aluminum-lithium alloys relies not just on melting the metal, but on strictly isolating it from the atmosphere to preserve its reactive components.

Summary Table:

| Feature | Impact on Aluminum-Lithium Production | Benefit |

|---|---|---|

| Negative Pressure | Maintains -0.1 MPa to -0.08 MPa | Prevents lithium oxidation & burning loss |

| Vacuum Degassing | Removes trapped hydrogen & atmospheric gases | Eliminates porosity for high structural purity |

| Composition Control | Eliminates unpredictable reactive loss | Ensures exact strength-to-weight ratio |

| Atmospheric Isolation | Protects molten lithium from oxygen | Achieves stable, repeatable chemical bonding |

Elevate Your Material Purity with KINTEK Advanced Vacuum Systems

Precision is non-negotiable when working with reactive elements like lithium. Backed by expert R&D and world-class manufacturing, KINTEK provides industry-leading Vacuum, CVD, Muffle, Tube, and Rotary systems designed to solve your most complex thermal challenges.

Whether you need to eliminate porosity or ensure stable alloy compositions, our high-temperature lab furnaces are fully customizable to meet your unique research and production needs.

Ready to optimize your alloying process? Contact us today to speak with a specialist and discover how KINTEK's precision technology can enhance your laboratory's efficiency and results.

Visual Guide

References

- Shulin Lü, Wei Guo. Enhancement of Strength–Ductility Synergy of Al-Li Cast Alloy via New Forming Processes and Sc Addition. DOI: 10.3390/ma17071558

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How is vacuum heat treatment applied to elastic alloys? Unlock Peak Performance in Aerospace and Medical Devices

- What technical advantages do vacuum high-temperature furnaces provide for sandwich panel brazing? Achieve Stronger Bonds

- Why is precise temperature and time control in a vacuum brazing furnace necessary for joint performance? Get Expert Tips

- What role does an industrial-grade vacuum furnace play in the brazing process of MnCoNiCuGe5 high-entropy alloys?

- How do the radiant heating and controlled cooling functions of a vacuum brazing furnace benefit Kovar-to-SS joints?