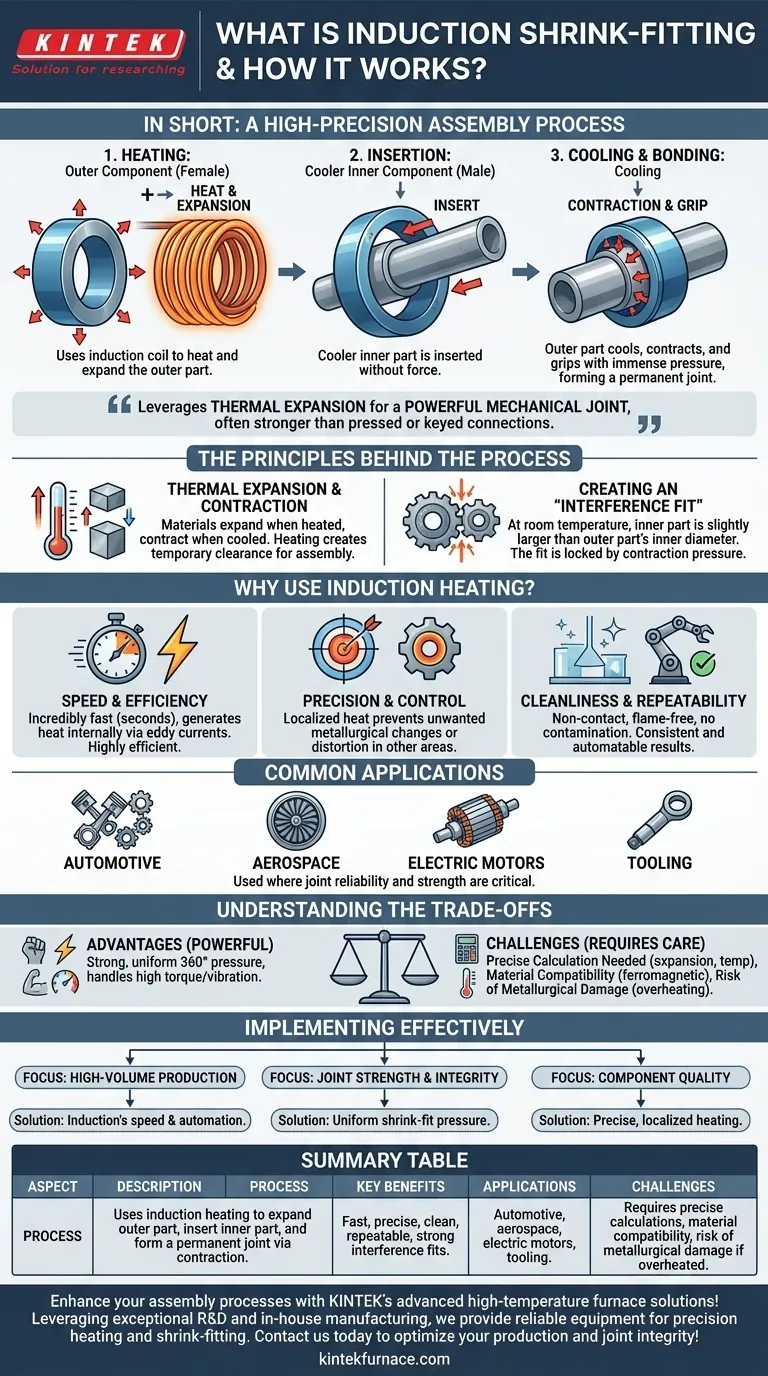

In short, induction shrink-fitting is a high-precision assembly process that uses heat to create a powerful mechanical bond. An outer component is heated with an induction coil, causing it to expand. A second, cooler component is then inserted, and as the outer part cools and contracts, it grips the inner part with immense pressure, forming a strong, permanent joint.

Induction shrink-fitting leverages the fundamental principle of thermal expansion, using clean and rapid induction heating to create a powerful mechanical joint that is often stronger and more reliable than a pressed fit or keyed connection.

The Principles Behind the Process

At its core, shrink-fitting is a game of controlled dimensions. The process manipulates the size of components using temperature to achieve a fit that would be impossible at an ambient state.

Thermal Expansion and Contraction

All materials expand when heated and contract when cooled. Induction shrink-fitting exploits this property by heating only the outer component, or "female" part.

This heating causes the part to expand just enough to increase its inner diameter, allowing the "male" component to be inserted without force.

As the heated part cools, it attempts to return to its original size, contracting tightly around the inner part. This contraction creates significant radial pressure, locking the two components together.

Creating an "Interference Fit"

The goal is to create what engineers call an interference fit. This means that at room temperature, the inner component's outer diameter is slightly larger than the outer component's inner diameter.

Without heat, forcing these parts together would require extreme pressure, potentially damaging them. The temporary expansion from induction heating is the key that unlocks the assembly.

Why Use Induction Heating?

While you could use an oven or a torch, induction heating offers unique advantages that make it the superior choice for modern manufacturing.

Speed and Efficiency

Induction heating is incredibly fast, often taking only seconds. An alternating magnetic field from a coil generates electrical currents (eddy currents) directly within the metal part itself, creating heat from the inside out. This is far more efficient than waiting for heat to transfer from an external source like an oven.

Precision and Control

The heat generated by induction can be localized to a very specific area. You can heat just the bore of a gear without affecting the temper of the gear teeth. This precision prevents unwanted metallurgical changes, distortion, or damage to the rest of the component.

Cleanliness and Repeatability

Because it's a non-contact, flame-free process, induction is exceptionally clean. There are no combustion byproducts or contamination. The process is also highly controllable and automatable, ensuring every part is heated to the exact same temperature for the exact same time, delivering consistent and repeatable results.

Common Applications

You will find induction shrink-fitting used in industries where joint reliability and strength are critical.

- Automotive: Mounting gears, bearings, and rings onto shafts.

- Aerospace: Fitting turbine discs and engine components.

- Electric Motors: Securing rotors to motor shafts.

- Tooling: Inserting carbide rings into high-performance tool holders.

Understanding the Trade-offs

While powerful, the process is not without its challenges and requires careful engineering.

The Need for Precise Calculation

Success depends on correct calculations. You must know the materials' coefficient of thermal expansion, the initial interference, and the ambient temperatures to determine the exact target temperature. Insufficient heating means the parts won't fit; excessive heating can permanently damage the material's properties.

Material Compatibility

The process works best on ferromagnetic metals like steel and iron, which respond well to induction. It also relies on the material having a suitable thermal expansion rate without being damaged by the required heat cycle.

Risk of Metallurgical Damage

Overheating a part is the biggest risk. For example, if you overheat a hardened steel gear, you can ruin its temper, making it soft and useless. Proper temperature control is not optional; it is essential to preserving the component's integrity.

Implementing Induction Shrink-Fitting Effectively

Choosing this method requires a clear understanding of your production goals.

- If your primary focus is high-volume production: Induction's unmatched speed and potential for automation make it the ideal solution for repeatable assembly on a production line.

- If your primary focus is joint strength and integrity: The uniform, 360-degree pressure of a shrink-fit creates a powerful bond that can handle high torque and vibration better than keys or set screws.

- If your primary focus is component quality: The precise, localized heating of induction protects sensitive areas of the part, minimizing the risk of warping or material damage.

By mastering the controlled application of heat, you can create some of the strongest and most reliable mechanical assemblies possible.

Summary Table:

| Aspect | Description |

|---|---|

| Process | Uses induction heating to expand outer part, insert inner part, and form a permanent joint via contraction. |

| Key Benefits | Fast, precise, clean, repeatable, and creates strong interference fits. |

| Applications | Automotive (gears, bearings), aerospace (turbine discs), electric motors, tooling. |

| Challenges | Requires precise calculations, material compatibility, and risk of metallurgical damage if overheated. |

Enhance your assembly processes with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs in precision heating and shrink-fitting. Contact us today to discuss how we can optimize your production and joint integrity!

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- What processing conditions does a vacuum furnace provide for TiCp/Fe microspheres? Sintering at 900 °C

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What is the purpose of performing medium vacuum annealing on working ampoules? Ensure Pure High-Temp Diffusion