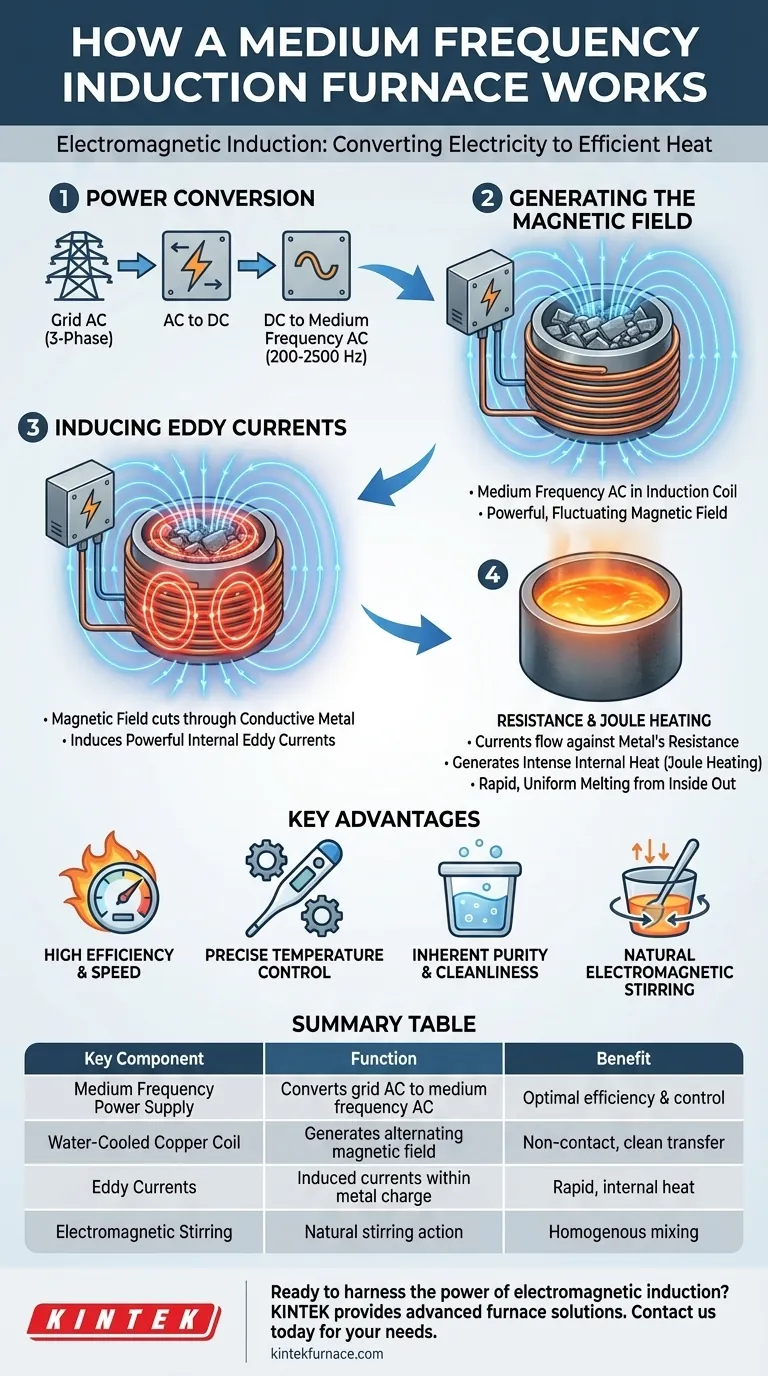

At its core, a medium frequency induction furnace operates on the principle of electromagnetic induction. It uses a powerful, fluctuating magnetic field to generate heat directly within the metal itself, rather than relying on external flames or heating elements. This process converts electrical energy into heat with remarkable efficiency and precision.

The fundamental principle is converting standard electrical current into a medium-frequency current, which is then used to create a magnetic field. This field induces powerful internal electrical currents (eddy currents) within the metal charge, and the metal's own resistance to these currents generates intense, rapid heat.

The Core Principle: From Electricity to Heat

The entire process is a multi-stage energy conversion, elegantly transforming electricity from the grid into thermal energy within a target material.

Step 1: Power Conversion

The furnace first takes standard three-phase alternating current (AC) from the power grid. This power is converted into direct current (DC) and then transformed back into a specialized, single-phase AC at a medium frequency, typically between 200 and 2,500 Hz. This frequency is critical for achieving optimal heating efficiency.

Step 2: Generating the Magnetic Field

This controlled, medium-frequency AC is fed into a water-cooled copper induction coil that surrounds the crucible holding the metal. As the current flows through this coil, it generates a powerful and rapidly alternating magnetic field in the space within and around the coil.

Step 3: Inducing Eddy Currents

According to Faraday's Law of Induction, this fluctuating magnetic field cuts through the conductive metal charge placed inside the crucible. This action induces a powerful electrical potential within the metal, causing circular flows of electrons known as eddy currents to form near the surface of the material.

Step 4: Resistance and Joule Heating

The metal itself has a natural electrical resistance. As the induced eddy currents flow against this resistance, they generate immense heat—a phenomenon known as Joule heating. The heat is generated inside the metal, leading to extremely rapid and uniform melting from the inside out.

Understanding the Key Advantages

The working principle of induction heating provides several distinct operational advantages over traditional furnace technologies.

High Efficiency and Speed

Because heat is generated directly within the charge material, energy losses to the surrounding environment are minimized. This results in very high electrical efficiency, low power consumption, and exceptionally fast melting and heating times.

Precise Temperature Control

The power supplied to the induction coil can be adjusted instantly and with great precision. This allows for exact control over the heating rate and final temperature of the molten metal, which is crucial for producing high-quality alloys.

Inherent Purity and Cleanliness

Induction heating is a non-contact process. There are no combustion byproducts like gas or soot, and the material never touches a heating element. This cleanliness is essential for melting reactive metals or creating high-purity alloys, a process often enhanced by operating the furnace under a vacuum or inert gas atmosphere.

Natural Electromagnetic Stirring

A unique benefit of this process is the electromagnetic stirring effect. The same magnetic forces that induce the eddy currents also create a stirring motion within the molten metal bath. This ensures the alloy is thoroughly mixed, leading to excellent chemical and temperature homogeneity.

Making the Right Choice for Your Application

Choosing an induction furnace is a decision based on the need for speed, precision, and purity.

- If your primary focus is rapid melting for foundries: The high efficiency and speed of a medium frequency furnace make it ideal for high-throughput production of various metals.

- If your primary focus is high-quality alloys and purity: The clean, non-contact heating and natural stirring action ensure a homogenous and uncontaminated final product.

- If your primary focus is localized heat treatment: The precise control is perfect for applications like forging, hardening shafts, or preheating welds where only a specific area requires heating.

This technology leverages fundamental physics to offer unparalleled control over the heating and melting of metals.

Summary Table:

| Key Component | Function | Benefit |

|---|---|---|

| Medium Frequency Power Supply | Converts grid AC to medium frequency AC (200-2500 Hz) | Enables optimal heating efficiency and control |

| Water-Cooled Copper Coil | Generates a powerful, alternating magnetic field | Provides non-contact, clean energy transfer |

| Eddy Currents | Induced currents flow within the metal charge | Generates rapid, internal heat via Joule heating |

| Electromagnetic Stirring | Natural stirring action from magnetic forces | Ensures homogenous mixing and temperature |

Ready to harness the power of electromagnetic induction for your metal processing needs?

KINTEK's advanced high-temperature furnace solutions are engineered for precision and performance. Leveraging our exceptional R&D and in-house manufacturing, we provide diverse laboratories and foundries with robust induction heating systems. Our product line, including specialized Muffle, Tube, and Vacuum & Atmosphere Furnaces, is complemented by strong deep customization capabilities to meet your unique experimental and production requirements.

Contact us today to discuss how our medium frequency induction furnace technology can deliver rapid melting, superior purity, and precise temperature control for your application.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What industries benefit from Vacuum Induction Melting Furnaces? Unlock High-Purity Metals for Aerospace, Medical, and More

- What are the main industrial applications of vacuum melting furnaces? Achieve Unmatched Material Purity and Performance

- What are the advantages of vacuum induction melting? Achieve Superior Purity for High-Performance Alloys

- How is operator safety ensured during the vacuum induction melting process? Discover Multi-Layered Protection for Your Lab

- How does vacuum induction melting work? Achieve Ultra-Pure, High-Performance Alloys