At its core, induction brazing uses a precisely controlled magnetic field to heat a joint, melting a filler metal that flows between two closely-fitted parts. This process happens without melting the base materials themselves, creating a strong, clean, and permanent metallurgical bond once the assembly cools. The speed and precision of induction heating make it a highly repeatable and efficient method for industrial manufacturing.

The essential advantage of induction brazing is not just that it joins metals, but that it delivers heat with surgical precision. This localized, rapid heating is ideal for high-volume production and protecting heat-sensitive components, a stark contrast to the slower, whole-part heating of a furnace.

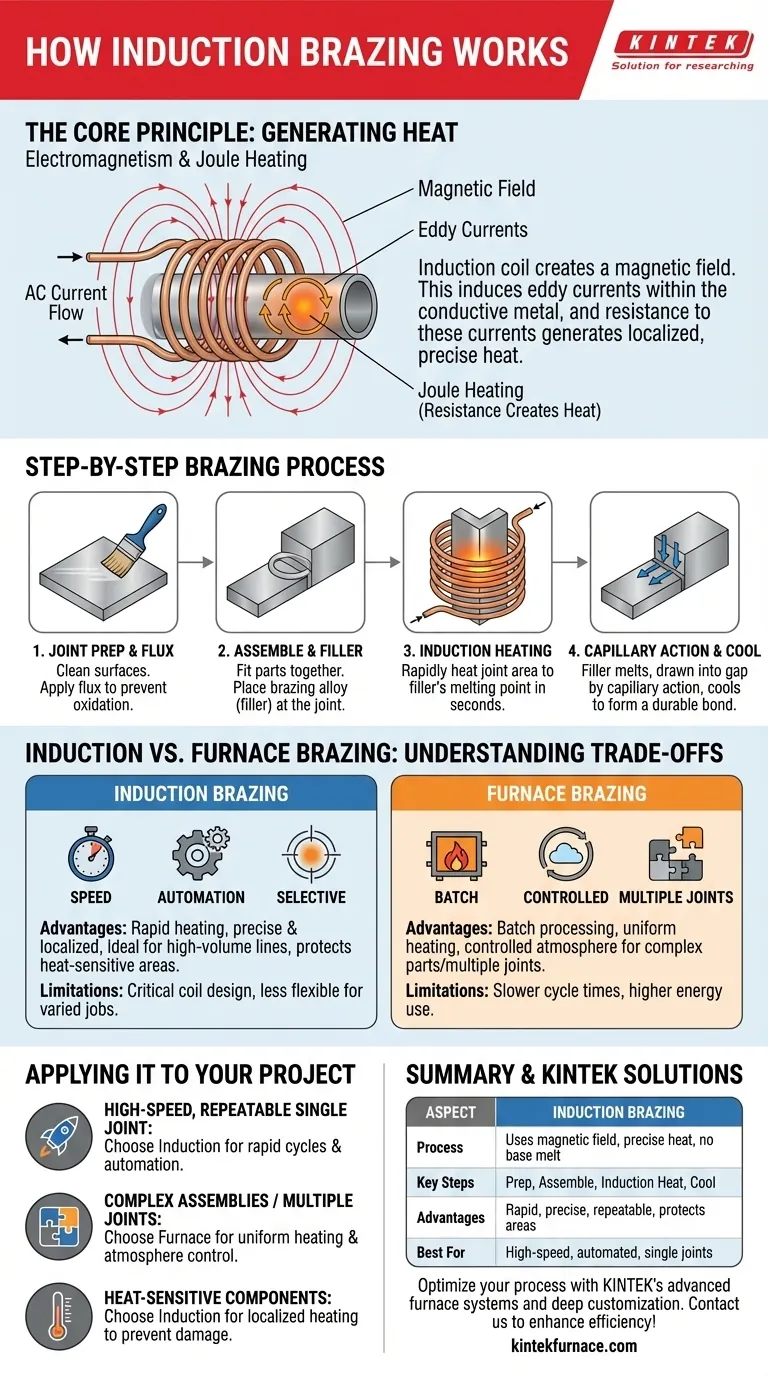

The Core Principle: How Induction Generates Heat

To understand induction brazing, you must first understand how it generates heat. The process is contactless and relies on fundamental principles of electromagnetism.

The Role of the Induction Coil

An induction coil, typically made of copper tubing, is the heart of the system. When a high-frequency alternating current (AC) flows through this coil, it generates a concentrated and rapidly alternating magnetic field around it.

Generating Eddy Currents

When a conductive material, like the metal parts to be brazed, is placed within this magnetic field, the field induces circular electrical currents within the metal. These are known as eddy currents.

Resistance Creates Heat

The metal parts have natural resistance to the flow of these eddy currents. This resistance creates intense, localized heat directly within the part itself—a phenomenon known as Joule heating. The heat is generated exactly where the magnetic field is strongest, allowing for incredibly precise temperature control.

The Step-by-Step Brazing Process

The practical application of induction heating for brazing follows a clear, repeatable sequence.

Step 1: Joint Preparation and Flux Application

The surfaces of the joint must be clean to ensure a strong bond. A flux is often applied to the joint area to prevent oxidation during heating and to help the molten filler metal flow smoothly.

Step 2: Assembling and Applying Filler Metal

The parts are fitted together, and the brazing alloy (filler metal) is placed at the joint. This alloy is often pre-formed into a ring, washer, or paste for easy and repeatable placement in production environments.

Step 3: Induction Heating

The assembly is positioned within the induction coil, and the power supply is activated. The joint area heats up rapidly, typically in a matter of seconds, reaching the melting temperature of the brazing alloy.

Step 4: Capillary Action and Cooling

As the filler metal melts, capillary action draws the liquid alloy into the small gap between the two base parts, completely filling the joint. The power is then shut off, and as the assembly cools, the filler metal solidifies, creating a durable, finished bond.

Understanding the Trade-offs: Induction vs. Furnace Brazing

Induction is not the only method for brazing. Its primary alternative is furnace brazing, and knowing the difference is critical for making the right engineering choice.

Advantage of Induction: Speed and Selectivity

Induction's main benefit is speed. It can heat a specific joint to brazing temperature in seconds, making it perfect for high-volume, automated production lines. Because it only heats the joint, it protects the rest of the component from thermal stress or damage.

Advantage of Furnace: Batch Processing and Atmosphere Control

Furnace brazing involves placing entire assemblies inside a furnace and heating them slowly in a controlled atmosphere (like a vacuum or inert gas such as argon). This prevents oxidation across the entire part and is ideal for complex geometries or brazing multiple joints on a single part simultaneously.

The Limitation of Induction: Coil Design is Critical

The effectiveness of induction brazing is entirely dependent on the design of the induction coil. The coil must be carefully shaped to match the joint geometry to ensure uniform heating. This requirement adds an upfront engineering cost and makes the process less flexible for one-off or varied jobs.

The Limitation of Furnace: Slower Cycle Times and Higher Energy Use

Heating an entire furnace and its contents is a slow process with long cycle times for heating and cooling. This makes it less suitable for a "single-piece flow" production model and generally consumes more energy per part compared to the focused heating of induction.

How to Apply This to Your Project

Your choice between induction and other methods depends entirely on your production goals, part geometry, and material properties.

- If your primary focus is high-speed, repeatable production of a single joint: Induction brazing is the superior choice due to its rapid heating cycles and suitability for automation.

- If your primary focus is brazing complex assemblies or multiple joints simultaneously: Furnace brazing provides the uniform heating and protective atmosphere needed for these challenging applications.

- If you are working with heat-sensitive components near the joint: The localized heating of induction is essential to prevent thermal damage to the surrounding material.

Ultimately, understanding the fundamental difference between localized induction heating and holistic furnace heating is the key to selecting the most effective and economical process for your application.

Summary Table:

| Aspect | Details |

|---|---|

| Process | Uses magnetic field to heat joint, melting filler metal without melting base materials |

| Key Steps | 1. Joint preparation and flux application |

- Assembly and filler metal placement

- Induction heating

- Capillary action and cooling | | Advantages | Rapid heating, precise temperature control, high repeatability, protects heat-sensitive areas | | Limitations | Dependent on coil design, less flexible for varied jobs | | Best For | High-speed production, automated lines, single joints | | Alternative | Furnace brazing for batch processing and complex geometries |

Optimize your brazing process with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, whether for induction brazing or other thermal applications. Contact us today to discuss how we can enhance your production efficiency and achieve superior results!

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

People Also Ask

- What are the primary advantages of using vacuum melting furnaces? Achieve Superior Purity and Control for High-Performance Materials

- What are the key advantages of melting metals under vacuum or protective atmospheres? Achieve Purity and Precision in Metal Processing

- Why is a water-cooled copper crucible used for Sm-Co-Fe alloys? Ensuring Purity in Vacuum Arc Furnaces

- What is the role of a vacuum induction melting furnace in Ti50Ni47Fe3 alloys? Achieve High Purity and Homogeneity

- Why is argon commonly used as a protective atmosphere in induction furnaces? Ensure Alloy Purity and Performance

- What is the function of an industrial vacuum induction melting furnace in the directional solidification of blades?

- What are the cost implications of using electric crucible furnaces? Uncover the True Total Cost of Ownership

- What is the role of vacuum induction furnaces in aluminum alloy oxidation research? Mastering Melt Environment Control