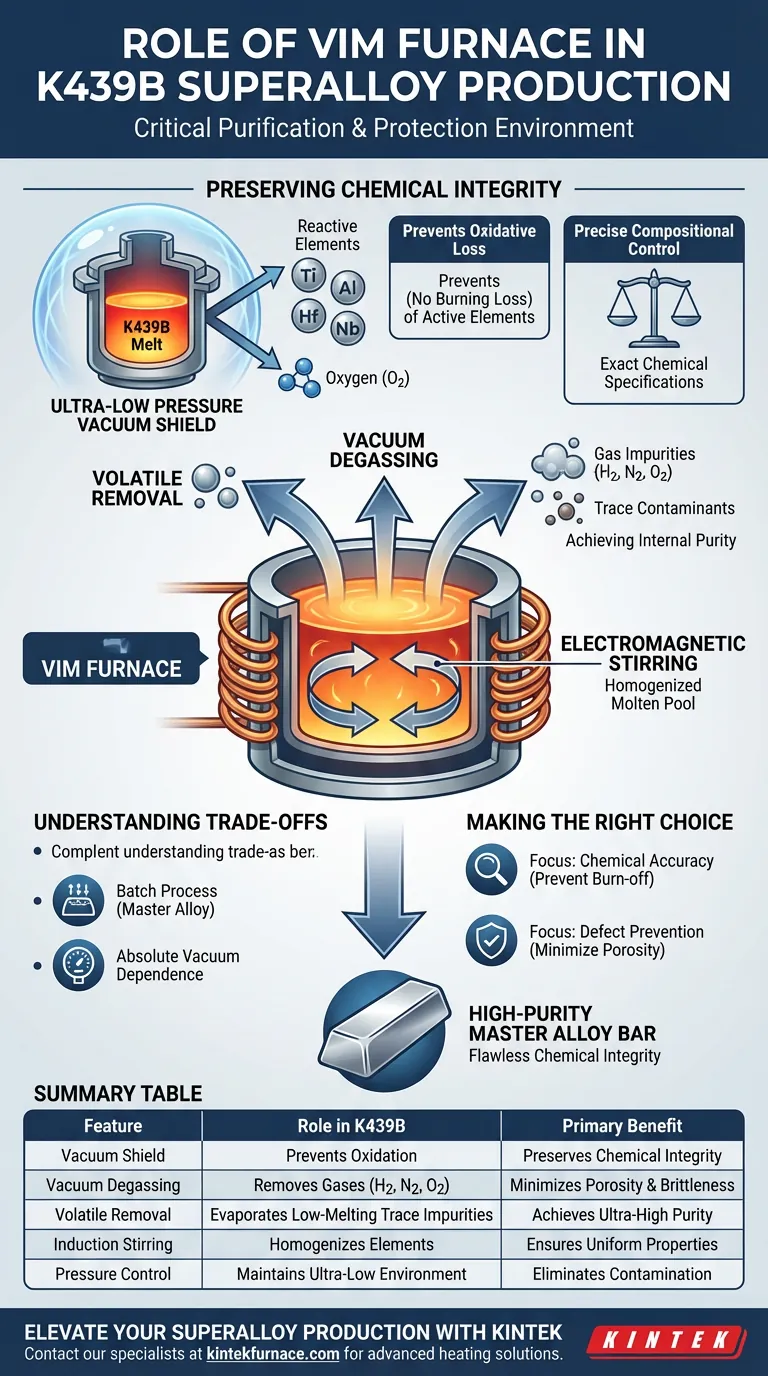

The vacuum induction melting (VIM) furnace acts as the critical purification and protection environment in the production of K439B superalloys. Its primary function is to provide an ultra-low pressure atmosphere that prevents the oxidative loss of active elements while simultaneously removing gaseous impurities through vacuum degassing, ensuring the creation of high-purity master alloy bars.

Core Takeaway The VIM furnace is not merely a melting vessel; it is a chemical processing tool. By isolating the K439B melt from the atmosphere, it safeguards reactive elements from burning off and actively strips out volatile contaminants, establishing the precise chemical baseline required for high-performance applications.

Preserving Chemical Integrity

The Shield Against Oxidation

The most immediate role of the VIM furnace is protection. K439B contains active elements that are highly reactive to oxygen at melting temperatures.

Without the protection of a vacuum, these elements would react with air and be lost as oxides (burning loss). The VIM furnace eliminates this risk by maintaining an ultra-low pressure environment. This ensures that the essential alloying elements remain in the solution rather than turning into slag.

Precise Compositional Control

Because the vacuum prevents the unpredictable loss of elements, metallurgists can achieve exact chemical specifications.

The furnace allows for the precise addition of reactive elements without the need for excessive "over-dosing" to compensate for losses. This results in a K439B alloy that strictly adheres to its designed formulation, which is critical for the material's final mechanical properties.

Achieving Internal Purity

Mechanism of Vacuum Degassing

Beyond protection, the VIM furnace plays an active role in purification. It utilizes vacuum degassing to physically pull impurities out of the liquid metal.

Under high vacuum, the solubility of gases like hydrogen, nitrogen, and oxygen decreases significantly. These gases escape from the melt and are pumped away, preventing porosity and brittleness in the final casting.

Elimination of Volatile Impurities

The vacuum environment facilitates the removal of harmful, low-melting-point trace elements.

These impurities have high vapor pressures and will volatilize (evaporate) out of the melt when subjected to the vacuum and heat of the VIM process. This results in a cast ingot with high internal purity, free from the contaminants that typically initiate structural failure.

Electromagnetic Stirring

While the vacuum handles the chemistry, the induction aspect of the furnace handles the physical mixing.

The induction heating mechanism naturally generates electromagnetic stirring within the molten pool. This vigorous motion ensures the melt is homogenous, distributing all alloying elements evenly throughout the matrix before the metal is cast into master alloy bars.

Understanding the Trade-offs

While VIM is essential for K439B, it is important to understand its operational boundaries.

VIM is primarily a batch process. It is optimized for creating the "master alloy"—the raw material stock. It produces high purity, but the solidification structure of the ingot formed in VIM may still require secondary remelting (such as VAR or ESR) if the end goal is a specific grain structure for a final component.

Vacuum dependence is absolute. The quality of the K439B is entirely dependent on the integrity of the vacuum seal. Even a minor leak or fluctuation in pressure (e.g., rising above the target Pascal range) can lead to immediate oxidation of active elements, compromising the entire batch.

Making the Right Choice for Your Goal

The VIM furnace is the foundational step for high-performance superalloy production. Depending on your specific quality metrics, focus on the following aspects:

- If your primary focus is Chemical Accuracy: Rely on the VIM's vacuum environment to prevent the "burn off" of reactive elements, ensuring your final analysis matches your target composition.

- If your primary focus is Defect Prevention: Leverage the vacuum degassing cycle to minimize gas content, which is the leading cause of porosity and voids in cast ingots.

The VIM furnace transforms K439B from a mixture of raw ingredients into a chemically precise, high-purity engineering material.

Summary Table:

| Feature | Role in K439B Production | Primary Benefit |

|---|---|---|

| Vacuum Shield | Prevents reactive element oxidation | Preserves chemical integrity & element yield |

| Vacuum Degassing | Removes H2, N2, and O2 gases | Minimizes porosity and internal brittleness |

| Volatile Removal | Evaporates low-melting trace impurities | Achieves ultra-high internal purity |

| Induction Stirring | Homogenizes molten alloying elements | Ensures uniform material properties |

| Pressure Control | Maintains ultra-low Pascal environment | Eliminates atmospheric contamination |

Elevate Your Superalloy Production with KINTEK

Precision is non-negotiable when working with high-performance materials like K439B. KINTEK provides industry-leading Vacuum Induction Melting (VIM) systems designed to deliver the ultra-low pressure environments and electromagnetic stirring required for flawless chemical integrity.

Backed by expert R&D and world-class manufacturing, we offer a full suite of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your specific metallurgical challenges. Whether you are refining master alloys or developing next-generation aerospace materials, our lab-scale and production high-temperature furnaces ensure your output meets the strictest purity standards.

Ready to optimize your melting and casting process?

Contact our specialists today to discuss your unique project requirements and discover how KINTEK’s advanced heating solutions can drive your success.

Visual Guide

References

- Yidong Wu, Xidong Hui. Evolution of Stress Rupture Property for K439B Superalloy During Long-Term Thermal Exposure at 800 °C. DOI: 10.3390/met14121461

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How is operator safety ensured during the vacuum induction melting process? Discover Multi-Layered Protection for Your Lab

- What are the overall benefits of using an induction gold melting furnace? Achieve Faster, Purer, and Safer Melts

- What are the main benefits of using graphite crucibles in induction furnaces? Achieve Superior Melting Efficiency & Consistency

- How does induction heating reduce energy costs? Achieve Up to 90% Energy Efficiency

- What is vacuum induction melting (VIM) and what is its primary purpose? Achieve Ultimate Purity in Metal Alloys

- What are the advantages of using a medium frequency vacuum induction furnace for NAB alloys? Precision & Purity

- What are the advantages of using a Vacuum Induction Melting Furnace over an ordinary open melting furnace? Achieve Purity and Precision in Metal Production

- What are the components and working principle of a coreless induction furnace? Discover Efficient Metal Melting Solutions