In induction furnace operations, the choice of a crucible is critical, and graphite is a dominant material for several key reasons. Graphite crucibles provide exceptional thermal shock resistance, excellent and uniform heat conduction, and the durability needed to withstand multiple melting cycles, ensuring both operational efficiency and metallurgical quality.

The primary benefit of a graphite crucible is not simply its ability to hold molten metal, but its active role in promoting stable, uniform, and repeatable heating, which is fundamental to achieving consistent results in metallurgy.

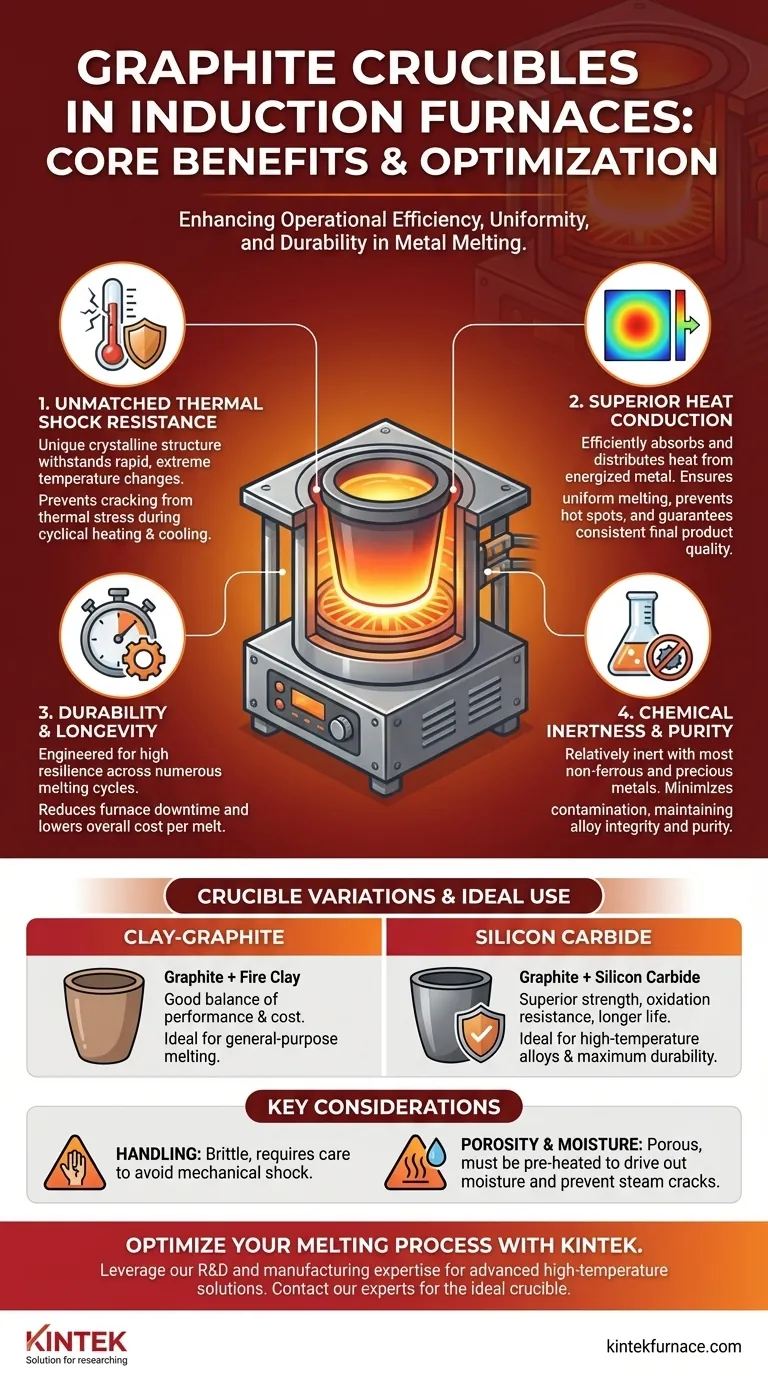

The Core Advantages of Graphite Explained

To understand why graphite is so prevalent, we must look beyond its high-temperature tolerance and examine its specific thermal and structural properties. These characteristics directly address the harsh, cyclical environment of an induction furnace.

Unmatched Thermal Shock Resistance

The most significant challenge inside an induction furnace is thermal shock—the stress a material endures from rapid and extreme temperature changes.

Graphite's unique crystalline structure allows it to expand and contract uniformly without developing the internal stresses that cause other materials to crack or fail. This makes it ideal for the rapid heating and cooling cycles inherent to furnace operations.

Superior Heat Conduction for Uniform Melting

Induction heating works by inducing electrical currents directly within the metal charge. The crucible's role is to manage and distribute this heat effectively.

Graphite is an excellent thermal conductor. It quickly absorbs heat from the energized metal and distributes it evenly throughout the entire melt. This prevents localized overheating (hot spots) and ensures a homogenous, consistent final product.

Durability and Longevity Across Cycles

A crucible is a consumable item, but its lifespan has a direct impact on operational costs and downtime.

Graphite crucibles are engineered for high durability, allowing them to be used for numerous melting cycles before replacement is necessary. This resilience reduces the frequency of furnace shutdowns and lowers the overall cost per melt.

Understanding the Trade-offs and Material Variations

While "graphite" is often used as a general term, different compositions exist, each with specific strengths. Understanding these variations is key to optimizing your process.

Clay-Graphite vs. Silicon Carbide

There are two primary categories of crucibles that incorporate graphite:

- Clay-Graphite Crucibles: These are made by mixing graphite with fire clay and other binders. They offer a good balance of performance and cost-effectiveness for many common applications.

- Silicon Carbide Crucibles: These crucibles blend silicon carbide with graphite. They provide superior mechanical strength, oxidation resistance, and even longer service life, but at a higher initial cost.

Chemical Inertness and Contamination

A crucible should be a passive container that does not react with or contaminate the molten metal.

Graphite is relatively inert with most common non-ferrous and precious metals, which is a major benefit for maintaining the purity of the alloy. However, for highly reactive metals, you may need to select a specific high-purity graphite grade or use a ceramic liner.

Handling and Porosity

Despite its thermal strength, graphite can be brittle and must be handled with care to avoid mechanical shock from being dropped or struck.

Crucibles are also porous and can absorb moisture from the air. It is critical to follow proper pre-heating procedures to slowly drive out any moisture, as trapped steam can cause the crucible to crack violently upon rapid heating.

Selecting the Right Crucible for Your Application

Your choice of crucible should be a deliberate decision based on your operational priorities and the metals you are melting.

- If your primary focus is cost-efficiency for general-purpose melting: A clay-graphite crucible provides the best balance of performance and affordability.

- If your primary focus is maximum durability and melting high-temperature alloys: A silicon carbide crucible is the superior choice for its extended lifespan and resistance.

- If your primary focus is maintaining the absolute purity of the melt: Select a high-purity graphite crucible and always verify its chemical compatibility with your specific alloy.

Understanding these material properties empowers you to treat the crucible not as a commodity, but as a critical component of a successful melting process.

Summary Table:

| Benefit | Key Advantage | Ideal For |

|---|---|---|

| Thermal Shock Resistance | Withstands rapid temperature changes without cracking | High-cycle, rapid heating/cooling operations |

| Heat Conduction | Promotes uniform melting and prevents hot spots | Applications requiring consistent, high-quality melts |

| Durability & Longevity | Extended service life across numerous melting cycles | Reducing operational costs and downtime |

| Chemical Inertness | Minimizes contamination of non-ferrous and precious metals | Maintaining melt purity and alloy integrity |

Optimize your induction melting process with a crucible designed for performance.

The right crucible is a critical component for achieving consistent, high-quality results and controlling operational costs. At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced high-temperature solutions tailored to your unique requirements.

Our expertise in materials like graphite and silicon carbide ensures you get a crucible that delivers on durability, thermal efficiency, and chemical compatibility.

Ready to enhance your melting operations? Contact our experts today to discuss the ideal crucible solution for your specific metals and furnace conditions.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

People Also Ask

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals