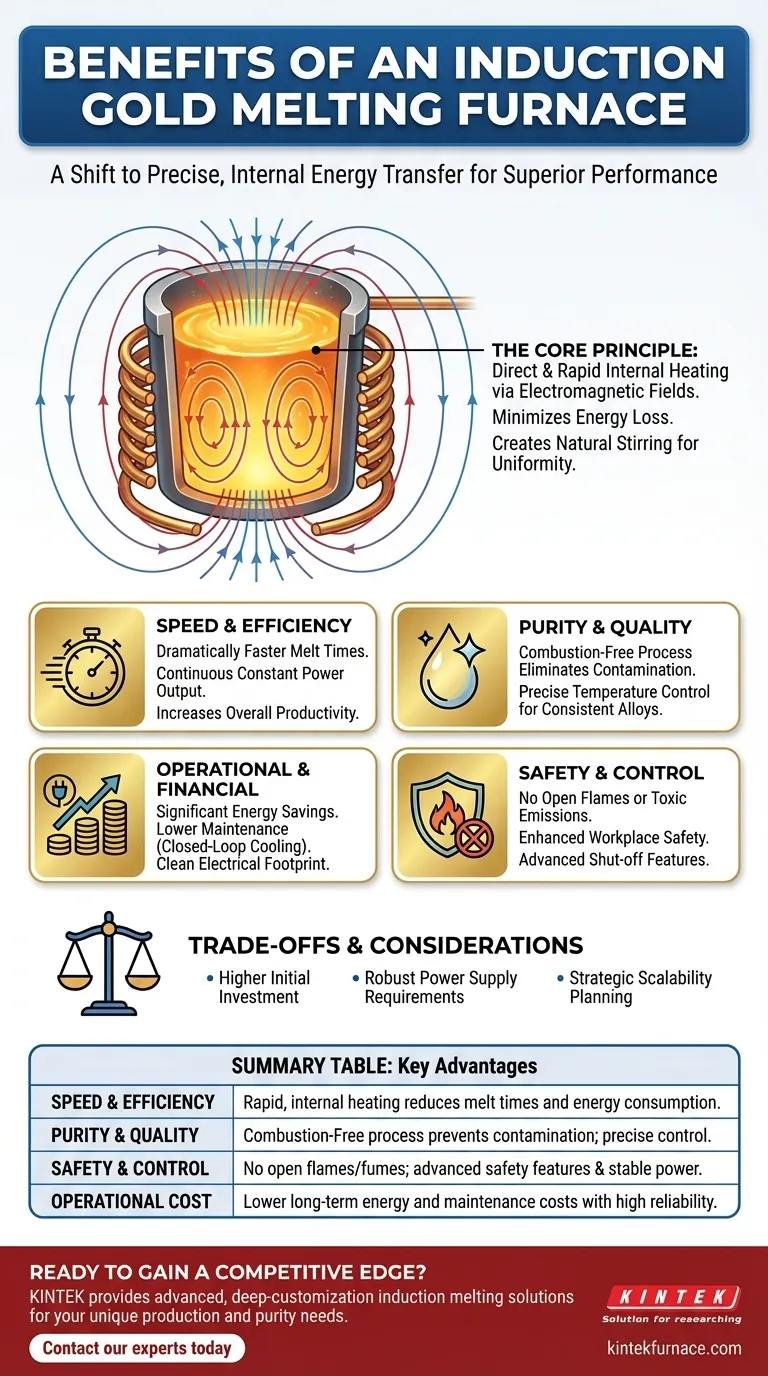

The core benefits of an induction gold melting furnace are its significant improvements in speed, purity, energy efficiency, and operational control over traditional methods. These furnaces use electromagnetic fields to heat the gold directly and internally, which results in dramatically faster melt times, a cleaner final product without contamination from combustion, and a safer work environment free from open flames.

An induction furnace is more than just a faster heater; it represents a shift from external, brute-force heating to precise, internal energy transfer. This fundamental difference is the source of its primary advantages in efficiency, metal quality, and operational cost, making it a strategic investment rather than a simple equipment upgrade.

The Core Principle: How Induction Drives Performance

Understanding how an induction furnace works is key to appreciating its benefits. Instead of burning fuel to create heat that is then transferred to the metal, an induction furnace generates an electromagnetic field. This field induces an electric current directly within the gold itself, causing it to heat up rapidly and uniformly from the inside out.

Direct and Rapid Heating

Because the heat is generated within the metal, there is minimal energy loss to the surrounding environment. This process is incredibly fast, significantly reducing the time it takes to bring a batch of gold from a solid to a liquid state and increasing overall productivity.

The Stirring Effect for Uniformity

The electromagnetic field also creates a natural stirring action within the molten metal. This ensures a homogenous mixture and uniform temperature throughout the crucible, which is critical for consistent alloy quality and preventing localized overheating or "hot spots" that can damage the crucible or degrade the metal.

Constant Power Output

Modern induction furnaces, particularly those using Insulated Gate Bipolar Transistor (IGBT) technology, can maintain a constant power output throughout the entire melting cycle. This means the melting speed does not decrease as the charge heats up, leading to predictable cycle times and superior energy efficiency compared to older technologies.

Achieving Superior Gold Purity and Quality

For any operation handling precious metals, purity is paramount. Induction technology provides a level of quality control that is difficult to achieve with fuel-fired furnaces.

Eliminating Contamination Sources

Traditional furnaces rely on the combustion of gas or other fuels, which introduces byproducts directly into the melting environment. These impurities can be absorbed by the molten gold, reducing its purity. Induction melting is a completely clean process with no combustion, thereby preserving the intrinsic value of the metal.

Precise Temperature Control

The power, and therefore the heat, of an induction furnace can be controlled with extreme precision by adjusting the frequency and current of the electromagnetic field. This allows operators to maintain the molten gold at an exact target temperature, preventing the vaporization of valuable alloys and ensuring consistent results batch after batch.

Operational and Financial Advantages

Beyond the metallurgical benefits, induction furnaces offer tangible improvements to a facility's bottom line and work environment.

Significant Energy Savings

The high efficiency of direct induction heating means more of the electrical energy consumed is converted directly into useful heat. This, combined with faster melt times, results in lower energy consumption per kilogram of gold melted, directly reducing operational costs.

Enhanced Workplace Safety

Induction melting eliminates the need for combustible gases and open flames, drastically reducing the risk of fire and explosion. The process generates no smoke or toxic emissions, creating a cleaner and safer atmosphere for employees. Modern units also feature comprehensive safety shut-offs for over-voltage, over-current, and water-cooling failures.

Lower Maintenance Burden

Many modern furnaces feature a closed-loop water circulation system that uses distilled water and heat exchangers for cooling. This design prevents the buildup of scale and mineral deposits that can clog cooling channels, a common point of failure in older systems. The result is less downtime, lower maintenance costs, and greater long-term reliability.

Cleaner Electrical Footprint

Advanced IGBT-based furnaces produce minimal harmonic pollution. This means they do not contaminate the facility's power grid or interfere with other sensitive electronic equipment, a significant advantage over older Silicon Controlled Rectifier (SCR) power supplies.

Understanding the Trade-offs and Considerations

While the benefits are substantial, a truly objective analysis requires acknowledging the associated trade-offs.

Higher Initial Investment

The technology behind induction furnaces is more complex than that of a simple gas furnace. This sophistication typically translates to a higher upfront capital cost for the equipment.

Power Supply Requirements

An induction furnace is a powerful electrical device and requires a robust electrical infrastructure to support it. Facilities may need to upgrade their power supply to accommodate the furnace's demands, which should be factored into the total cost of implementation.

Strategic Scalability Planning

When investing in an induction system, it is crucial to consider future production needs. Choosing a furnace that can be scaled or adapted to handle larger volumes will prevent the need for a costly full replacement as your business grows.

Making the Right Choice for Your Operation

The decision to invest in an induction furnace should be aligned with your specific operational priorities.

- If your primary focus is maximizing throughput and speed: The constant power output and rapid heating of an induction furnace will deliver the most significant productivity gains.

- If your primary focus is achieving the highest possible purity: The contactless, combustion-free heating method eliminates external contamination, making it the superior choice for high-value melts.

- If your primary focus is long-term operational cost reduction: The combination of high energy efficiency and lower maintenance provides a clear path to a lower total cost of ownership.

- If you are starting a new or expanding facility: Prioritizing a modern IGBT induction furnace ensures a clean power footprint and future-proofs your operation.

Ultimately, adopting induction technology is a strategic decision to gain a competitive edge through superior process control, quality, and efficiency.

Summary Table:

| Benefit | Key Advantage |

|---|---|

| Speed & Efficiency | Rapid, internal heating reduces melt times and energy consumption. |

| Purity & Quality | Combustion-free process prevents contamination; precise temperature control. |

| Safety & Control | No open flames or toxic fumes; advanced safety features and stable power output. |

| Operational Cost | Lower long-term energy and maintenance costs with high reliability. |

Ready to gain a competitive edge with superior gold melting?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides jewelers, refiners, and mining operations with advanced induction melting solutions. Our product line, including Crucible and Vacuum Induction Furnaces, is complemented by our strong deep customization capability to precisely meet your unique production and purity requirements.

Contact our experts today to discuss how a KINTEK induction furnace can optimize your melting process, improve your bottom line, and ensure the highest quality results.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the main applications of vacuum induction melting (VIM) furnaces? Achieve Unmatched Metal Purity for Critical Industries

- What are the key features and benefits of a Vacuum Induction Melting Furnace? Achieve High-Purity Metal Production

- What components make up a Vacuum Induction Melting Furnace? Discover the Key Systems for Pure Metal Melting

- What are the advantages of vacuum induction melting? Achieve Superior Purity for High-Performance Alloys

- How is operator safety ensured during the vacuum induction melting process? Discover Multi-Layered Protection for Your Lab