The primary advantage is absolute control over alloy chemistry and structure. A medium frequency vacuum induction furnace solves the two most critical challenges in melting Nickel-Aluminum Bronze (NAB): the oxidative loss of reactive elements and the separation of heavy elements. By combining a vacuum environment to protect the chemistry with electromagnetic stirring to homogenize the structure, this method produces high-purity alloys that conventional electric arc or gas furnaces cannot replicate.

Core Takeaway Conventional melting often struggles with the contrasting densities and melting points of NAB components. Medium frequency vacuum induction overcomes this by preventing the loss of active ingredients like aluminum while forcing the uniform diffusion of iron and nickel through electromagnetic stirring.

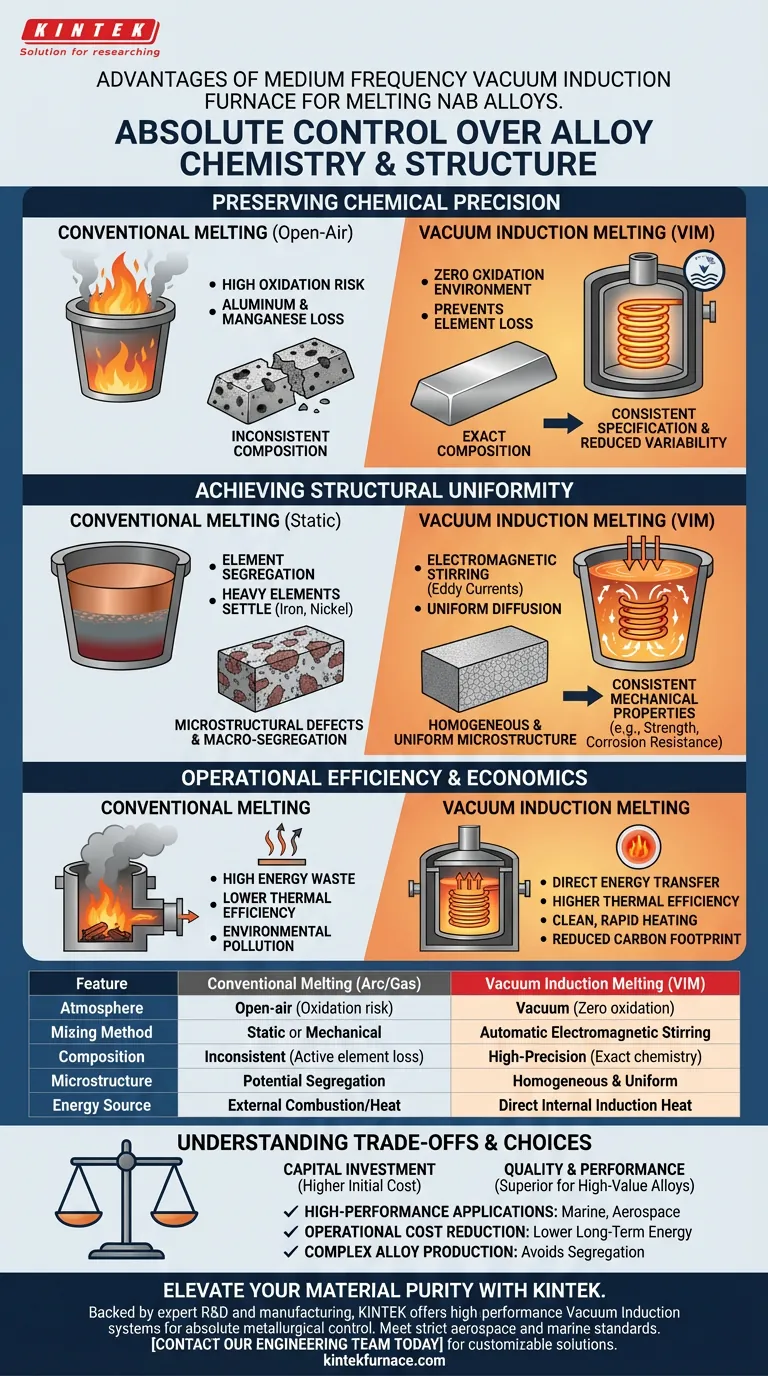

Preserving Chemical Precision

The chemistry of Nickel-Aluminum Bronze is delicate. Achieving the correct mechanical properties requires maintaining exact ratios of reactive elements, which is difficult in open-air environments.

Preventing Oxidative Loss

Aluminum and manganese are active elements critical to NAB alloys. In conventional melting, high temperatures cause these elements to oxidize rapidly when exposed to air.

A vacuum environment eliminates oxygen from the equation. This effectively prevents the burning off of these active elements, ensuring that the material you put into the furnace is the material that ends up in the casting.

Ensuring Exact Composition

Because oxidation is minimized, manufacturers do not need to "overcharge" the melt with extra aluminum to compensate for predicted losses.

This allows for precise control over the chemical composition. You achieve the target specification consistently, reducing the variability often seen in batches melted via electric arc or cupola methods.

Achieving Structural Uniformity

NAB alloys contain elements with vastly different melting points and densities. The "medium frequency" aspect of the furnace addresses the physical challenge of mixing these components.

The Mechanics of Electromagnetic Stirring

Medium frequency induction generates eddy currents within the molten metal. These currents create a strong, natural convection effect known as electromagnetic stirring.

Unlike static melting methods, this forces the melt to move vigorously. It mixes the alloy continuously without the need for mechanical paddles or gas injection, which can introduce contaminants.

Diffusing High-Melting-Point Elements

Iron and nickel are essential for the strength of NAB, but they have high melting points and are denser than the copper matrix.

In conventional furnaces, these heavy elements can settle or clump, leading to segregation. The electromagnetic stirring effect promotes the uniform diffusion of iron and nickel throughout the copper matrix.

Eliminating Microstructural Defects

By keeping the heavy elements suspended and distributed, the process reduces macro-segregation.

This results in a uniform microstructure across the entire ingot or casting. A homogeneous structure ensures that mechanical properties—such as tensile strength and corrosion resistance—are consistent throughout the component.

Operational Efficiency and Economics

Beyond material quality, induction technology offers distinct operational advantages over traditional combustion or electric arc methods.

Direct Energy Transfer

Traditional furnaces lose significant energy through heat dissipation to the surrounding air.

Induction furnaces heat the metal directly through electromagnetic fields. This concentrates almost all energy on melting the material, leading to higher thermal efficiency and reduced energy waste.

Cleanliness and Speed

Induction melting provides rapid heating capabilities.

Because it does not rely on combustion, it eliminates environmental pollution associated with burning propane or coke. This creates a cleaner, safer working environment and reduces the carbon footprint of the operation.

Understanding the Trade-offs

While medium frequency vacuum induction is superior for quality, it is important to recognize where it fits in the production hierarchy.

Capital vs. Quality

This technology represents a significant investment compared to simple gas-fired crucibles. It is best justified when material specifications are tight and the cost of casting failure is high.

Batch Processing Limits

Vacuum induction melting is typically a batch process. While excellent for high-value alloys, it may not match the sheer throughput volume of continuous casting methods used for lower-grade commodity copper products.

Making the Right Choice for Your Project

The decision to switch to medium frequency vacuum induction depends on the specific demands of your end-use application.

- If your primary focus is High-Performance Applications: Use this furnace type to ensure the compositional exactness and structural integrity required for marine or aerospace components.

- If your primary focus is Operational Cost Reduction: Leverage the high thermal efficiency and reduced need for remelting to lower long-term energy and labor costs.

- If your primary focus is Complex Alloy Production: Rely on the electromagnetic stirring capability to mix elements with vastly different densities that would otherwise segregate.

Ultimately, this technology transforms metal melting from a simple heating process into a precise chemical engineering operation.

Summary Table:

| Feature | Conventional Melting (Arc/Gas) | Vacuum Induction Melting (VIM) |

|---|---|---|

| Atmosphere | Open-air (Oxidation risk) | Vacuum (Zero oxidation) |

| Mixing Method | Static or Mechanical | Automatic Electromagnetic Stirring |

| Composition | Inconsistent (Active element loss) | High-Precision (Exact chemistry) |

| Microstructure | Potential Segregation | Homogeneous & Uniform |

| Energy Source | External Combustion/Heat | Direct Internal Induction Heat |

Elevate Your Material Purity with KINTEK

Don't let oxidative loss or element segregation compromise your high-performance NAB alloys. Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum Induction, Tube, and Muffle systems designed to give you absolute control over your metallurgical outcomes. Whether you need a standard laboratory furnace or a fully customizable high-temperature system, our technology ensures your materials meet the strictest aerospace and marine standards.

Contact Our Engineering Team Today to discuss how our customizable vacuum systems can optimize your melting process.

Visual Guide

References

- Yinxun Tan, Zhao Yizhi. Effect of Al/Ni Ratio on the Microstructure and Properties of Nickel–Aluminum Bronze Alloys. DOI: 10.3390/ma17061330

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Magnesium Extraction and Purification Condensing Tube Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- What are the maintenance benefits of using IGBT technology in induction melting? Maximize Uptime & Reduce Downtime

- How can I reduce the power consumption of my induction furnace? Achieve Major Energy Savings Now

- What makes induction heating more precise than other methods? Discover Unmatched Control & Speed

- How do induction furnaces contribute to cost savings in the long term? Unlock Long-Term Efficiency and ROI

- What are the limitations of induction heating? High Costs, Material Limits, and EMI Explained

- What are the main components of a steel shell structure induction furnace? An In-Depth System Breakdown

- Why is a Vacuum Induction Melting (VIM) furnace preferred for AlCoCrFeNi High-Entropy Alloys? Achieve Peak Purity.

- What factors should be considered when selecting an induction melting furnace? A Guide to Maximizing ROI