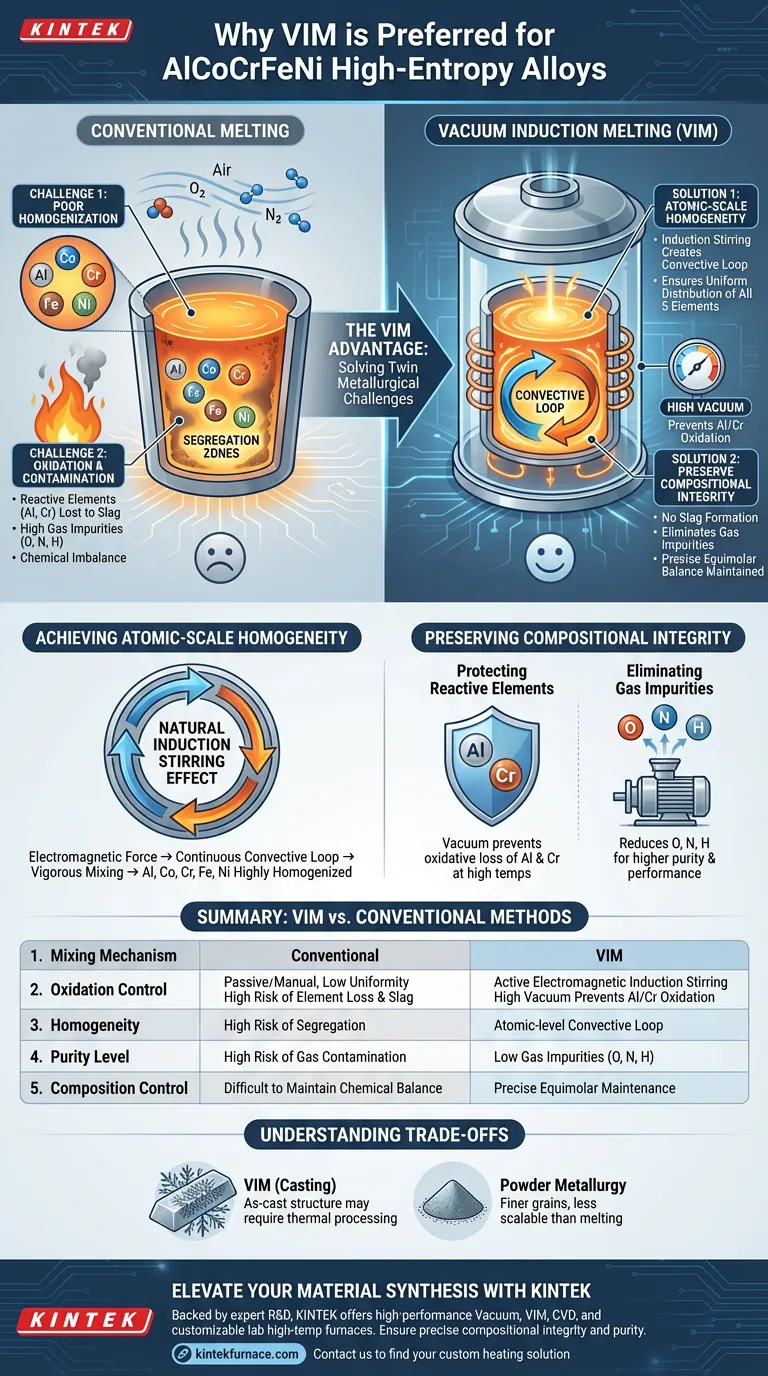

The preference for Vacuum Induction Melting (VIM) when preparing equimolar AlCoCrFeNi alloys stems from its unique ability to solve the twin metallurgical challenges of multi-element homogenization and oxidation control. Conventional melting methods often struggle to mix five distinct elements without contamination or segregation. VIM utilizes a high-vacuum environment to prevent the degradation of reactive elements like Aluminum and Chromium, while simultaneously employing electromagnetic induction to vigorously stir the molten pool for atomic-level uniformity.

Core Takeaway For high-entropy alloys like AlCoCrFeNi, maintaining a precise equimolar ratio is critical for the material's properties. VIM is the preferred method because it generates a natural convective loop that ensures all five metals mix intimately, while the vacuum prevents the loss of active elements that would otherwise alter the alloy's chemical balance.

Achieving Atomic-Scale Homogeneity

The Power of Induction Stirring

The defining feature of VIM is the natural induction stirring effect. Unlike conventional resistance furnaces, the electromagnetic field used to heat the metal generates strong stirring forces within the crucible.

Creating a Convective Loop

This electromagnetic force creates a continuous convective loop in the molten metal. This physical movement is not merely helpful; it is essential when combining five elements with potentially different melting points and densities.

Ensuring Uniform Distribution

The vigorous mixing action ensures that the Al, Co, Cr, Fe, and Ni atoms are highly homogenized. Without this active stirring, the melt pool could suffer from segregation, where elements cluster rather than mixing evenly, compromising the "high entropy" nature of the alloy.

Preserving Compositional Integrity

Protecting Reactive Elements

AlCoCrFeNi contains Aluminum (Al) and Chromium (Cr), both of which are highly active elements that oxidize rapidly at high temperatures. Conventional melting in air would lead to significant loss of these elements through slag formation.

The Role of High Vacuum

The high-vacuum environment effectively isolates the melt from oxygen. This prevents the oxidative loss of Al and Cr, ensuring the final ingot retains the precise equimolar composition calculated for the experiment.

Eliminating Gas Impurities

Beyond preventing oxidation, the vacuum environment actively degasses the melt. It significantly reduces the content of gas impurities such as oxygen, nitrogen, and hydrogen, which are detrimental to the alloy's purity and mechanical performance.

Understanding the Trade-offs

Cast Structures vs. Powder Metallurgy

While VIM excels at creating pure ingots, it is fundamentally a casting process. It creates a "as-cast" structure which may still contain dendritic formations (tree-like crystal structures) during solidification.

Processing Requirements

Because of these dendritic structures, VIM ingots often require subsequent thermal processing or hot working to fully optimize the grain structure. This contrasts with methods like vacuum hot pressing (a powder metallurgy route), which can produce finer grains directly but may lack the scalability of melting.

Making the Right Choice for Your Goal

While VIM is the superior choice for casting high-purity ingots, understanding your specific project needs is vital.

- If your primary focus is Compositional Accuracy: Rely on VIM to prevent the loss of Aluminum and Chromium, ensuring your final alloy matches your theoretical calculations.

- If your primary focus is Homogeneity: Trust the induction stirring of VIM to mix the five distinct elements more thoroughly than static melting methods can.

- If your primary focus is Microstructural Control: Be aware that VIM ingots may require secondary processing (like forging or annealing) to break down cast dendrites, unlike powder metallurgy methods.

VIM provides the cleanest, most chemically consistent foundation for high-entropy alloy development, acting as the critical first step in high-performance material synthesis.

Summary Table:

| Feature | Vacuum Induction Melting (VIM) | Conventional Melting Methods |

|---|---|---|

| Mixing Mechanism | Active electromagnetic induction stirring | Passive/Manual mixing (low uniformity) |

| Oxidation Control | High vacuum prevents Al/Cr oxidation | High risk of element loss & slag formation |

| Homogeneity | Atomic-level convective loop | High risk of element segregation |

| Purity Level | Low gas impurities (O, N, H) | High risk of gas contamination |

| Composition Control | Precise equimolar maintenance | Difficult to maintain chemical balance |

Elevate Your Material Synthesis with KINTEK

Ready to achieve unmatched homogeneity in your high-entropy alloy production? Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum, VIM, CVD, and customizable lab high-temp furnaces specifically designed to meet the rigorous demands of advanced metallurgy.

Whether you are refining equimolar AlCoCrFeNi or developing next-generation materials, our systems ensure precise compositional integrity and elimination of impurities. Contact us today to find your custom heating solution and see how our expertise can optimize your research outcomes.

Visual Guide

References

- Mudassar Hussain, Tuty Asma Abu Bakar. X-Ray Diffraction Analysis of Sigma-Phase Evolution in Equimolar AlCoCrFeNi High Entropy Alloy. DOI: 10.15282/ijame.21.4.2024.14.0917

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the benefits of vacuum induction smelting technology? Achieve Superior Purity and Performance for Advanced Materials

- What are the primary advantages of using vacuum melting furnaces? Achieve Superior Purity and Control for High-Performance Materials

- What are the technical advantages of using a high vacuum arc furnace? Unlock High-Purity Magnetic Alloys

- How are medium frequency induction furnaces used in metal melting and casting? Unlock Precision & Efficiency

- How do induction melting furnaces ensure superior metal quality? Achieve Purity, Homogeneity & Control

- How is the penetration depth of eddy currents determined in induction heating? Master Frequency, Resistivity, and Permeability

- What types of materials can be smelted in an induction furnace? Master the Art of Clean, Efficient Metal Melting

- What safety advantages do induction gold melting furnaces offer? Flameless, Contained Melting for Maximum Operator Safety