The defining safety advantage of induction gold melting furnaces is their fundamentally different method of heating. By using electromagnetic fields to generate heat directly within the gold itself, they operate without open flames or external heating elements, drastically reducing the risk of fires, burns, and exposure to toxic combustion byproducts common to traditional furnaces.

The core safety principle of induction melting is containment. Because heat is generated internally within the metal inside an enclosed crucible, the most significant external hazards—open flames, superheated surfaces, and noxious fumes—are eliminated from the process by design.

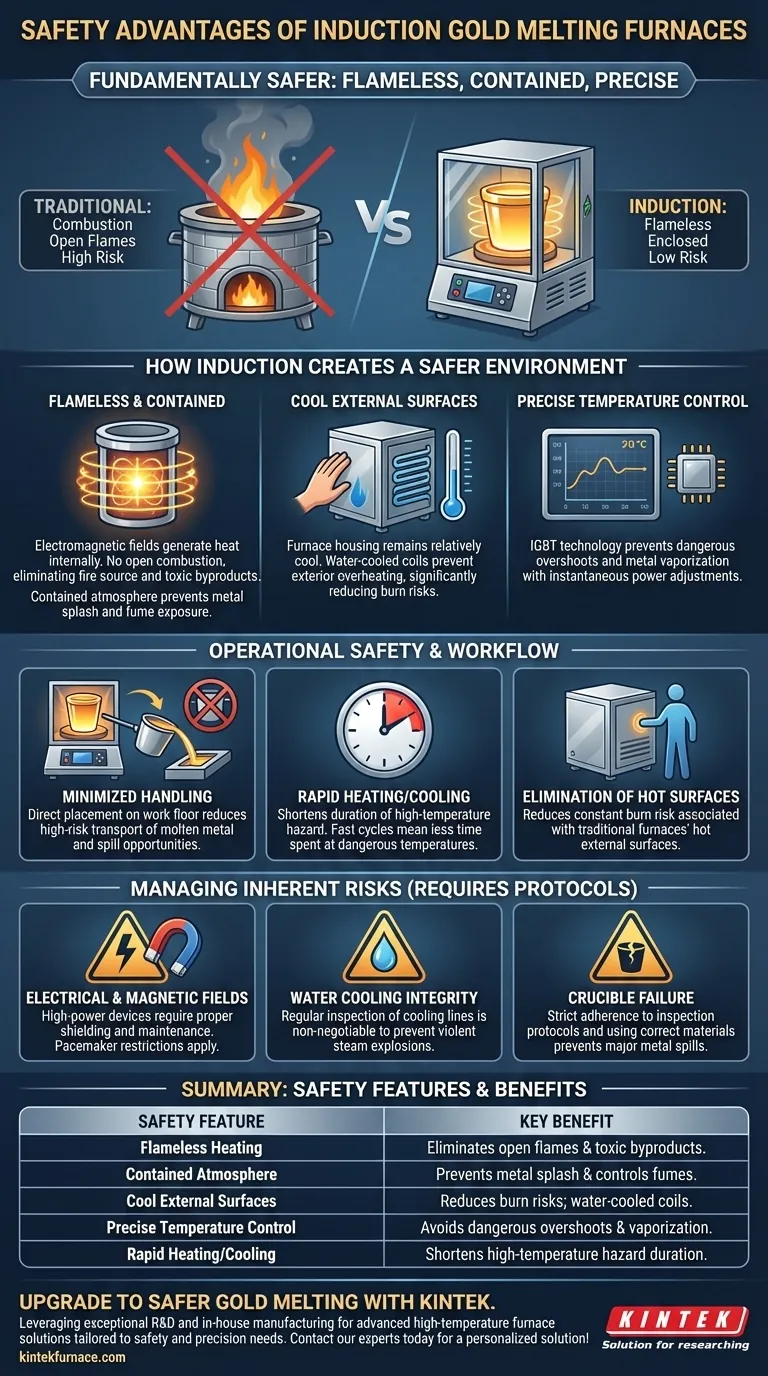

How Induction Creates a Safer Melting Environment

Understanding the "how" reveals why induction is an inherently safer technology. The safety benefits are not add-ons; they are a direct result of the physics behind the process.

The Principle of Flameless Heating

An induction furnace uses a powerful, alternating magnetic field. This field induces strong electrical currents within the gold, and the metal's natural resistance to this current flow generates rapid, precise heat.

This process is entirely flameless. Unlike gas or torch methods, there is no combustion, which immediately removes the primary ignition source for workplace fires.

A Contained and Controlled Atmosphere

The melting takes place inside a crucible, which is often housed in a sealed chamber. This enclosure provides two major safety benefits.

First, it contains any potential metal splash. Second, it allows for control over the atmosphere, often operating with low oxygen levels. This not only prevents the oxidation of the gold but also suppresses the creation of harmful fumes and further reduces fire risk.

The Role of Precise Temperature Control

Induction systems offer exceptional control over temperature. IGBT (Insulated-Gate Bipolar Transistor) technology allows for instantaneous power adjustments, preventing the dangerous temperature overshoots that can occur with less responsive systems.

This precision minimizes the risk of vaporizing the metal, damaging equipment, or creating an unnecessarily hazardous high-temperature environment.

Operational Safety and Workflow Improvements

Beyond the core technology, induction furnaces improve the safety of the day-to-day workflow.

Elimination of Exposed Hot Surfaces

Traditional furnaces have external surfaces that remain dangerously hot long after use, creating a constant burn risk.

Induction furnaces heat the metal, not the machine. While the crucible becomes extremely hot, the furnace housing itself and the induction coils (which are water-cooled) remain relatively cool, significantly reducing the chance of accidental contact burns.

Minimized Handling of Molten Material

The speed and compact nature of induction systems often allow them to be placed directly on the work floor. This can eliminate the need to transport ladles of molten metal across a facility, one of the most high-risk activities in any casting operation.

Reducing the movement of molten material directly reduces the opportunity for catastrophic spills.

Rapid Heating and Cooling Cycles

An induction furnace can bring gold to its melting point in minutes or even seconds and cools down quickly once powered off.

This shortens the duration that a high-temperature hazard exists in the workspace, creating a safer operational cadence compared to systems that must be pre-heated for long periods and stay hot for hours.

Understanding the Inherent Risks

No industrial heating process is without risk. While induction technology eliminates many traditional hazards, it introduces new ones that require proper management and training.

Electrical and Magnetic Field Hazards

Induction furnaces are high-power electrical devices. They must be installed and maintained correctly to prevent the risk of electric shock.

They also generate powerful magnetic fields. All personnel must be trained on these risks, and individuals with pacemakers or other medical implants must be prohibited from the immediate area. Proper shielding is a critical design feature.

Water Cooling System Integrity

The induction coils require a water cooling system to prevent them from overheating. A water leak in the vicinity of molten metal is extremely dangerous, as it can cause a violent steam explosion.

Regular inspection and maintenance of all cooling lines and connections are non-negotiable safety procedures.

Crucible Failure

The crucible is the primary vessel containing the molten gold. Using a crucible that is cracked, damaged, or not rated for the target temperature can lead to failure and a major metal spill.

Strict adherence to crucible inspection protocols and using the correct material, such as high-purity graphite or ceramic, is essential.

Making the Right Choice for Your Goal

Your choice of melting technology should be based on a complete assessment of safety, efficiency, and operational needs.

- If your primary focus is maximizing operator safety: Induction is the superior choice due to its enclosed, flameless design that minimizes burn risk and fume exposure.

- If your primary focus is process control and metal purity: Induction offers unparalleled temperature precision and a controlled atmosphere, ensuring consistent, high-quality results.

- If your primary focus is workflow integration and speed: The rapid cycles and smaller footprint of induction furnaces allow for safer, more efficient integration directly into a production line.

Ultimately, investing in induction technology is an investment in a fundamentally safer and more controlled melting process.

Summary Table:

| Safety Feature | Key Benefit |

|---|---|

| Flameless Heating | Eliminates open flames and toxic combustion byproducts. |

| Contained Atmosphere | Prevents metal splash and controls fume exposure. |

| Cool External Surfaces | Reduces burn risks; coils are water-cooled. |

| Precise Temperature Control | Avoids dangerous overshoots and metal vaporization. |

| Rapid Heating/Cooling | Shortens high-temperature hazard duration. |

Upgrade to a safer, more efficient gold melting process with KINTEK.

Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnace solutions tailored to your lab's unique safety and precision needs. Our product line—including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is backed by deep customization capabilities to ensure your specific experimental requirements are met with the highest safety standards.

Ready to enhance your lab's safety and performance? Contact our experts today for a personalized solution!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What components make up a Vacuum Induction Melting Furnace? Discover the Key Systems for Pure Metal Melting

- What are the advantages of vacuum induction melting? Achieve Superior Purity for High-Performance Alloys

- How is operator safety ensured during the vacuum induction melting process? Discover Multi-Layered Protection for Your Lab

- What industries benefit from Vacuum Induction Melting Furnaces? Unlock High-Purity Metals for Aerospace, Medical, and More

- What are the key features and benefits of a Vacuum Induction Melting Furnace? Achieve High-Purity Metal Production