In essence, medium frequency induction furnaces use a powerful, non-contact method of electromagnetic induction to melt metal for casting. An alternating current is passed through a coil, which generates a magnetic field that induces electrical currents directly within the metal charge, causing it to heat rapidly and melt from the inside out with exceptional precision.

The core value of medium frequency induction furnaces is not just melting metal, but doing so with a level of control, efficiency, and cleanliness that traditional methods cannot match. This translates directly to higher-quality final products, reduced operational costs, and greater manufacturing flexibility.

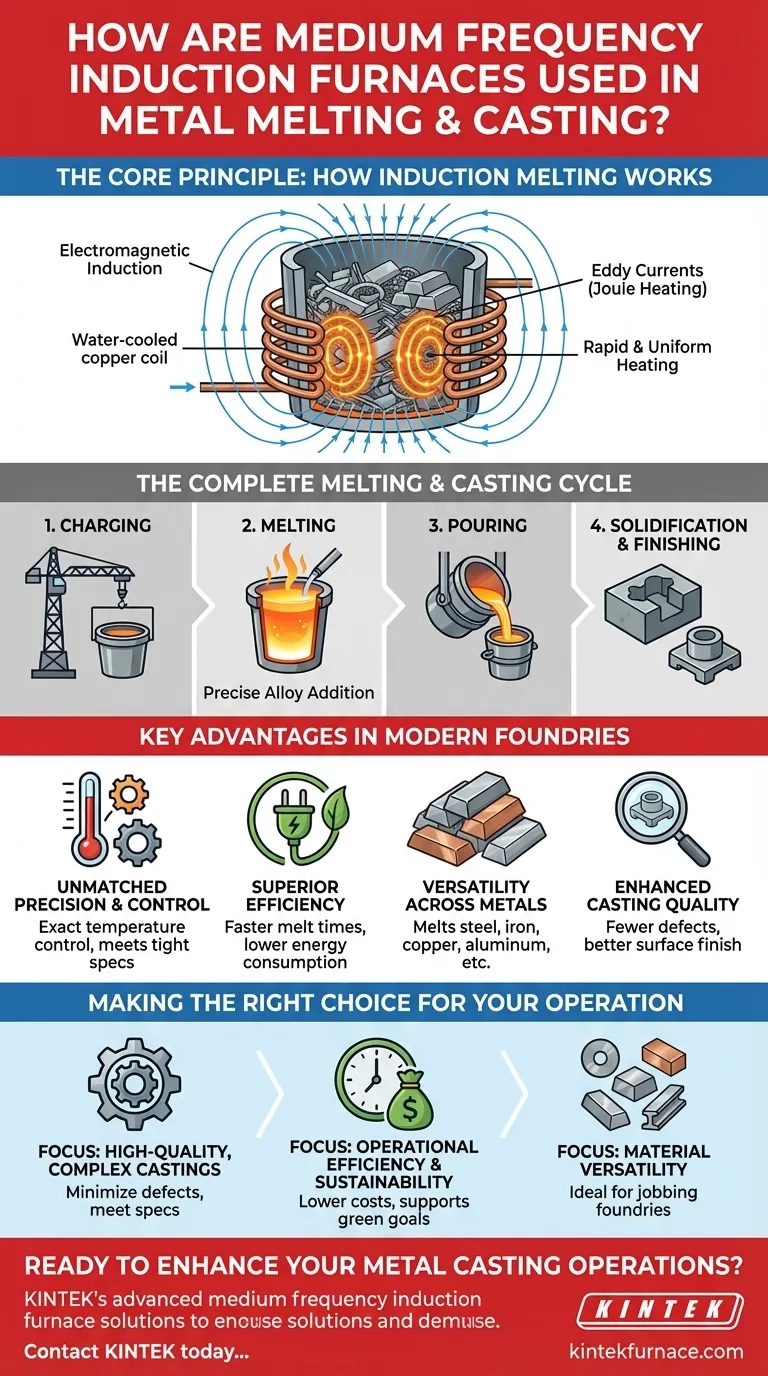

The Core Principle: How Induction Melting Works

To understand the application, you must first grasp the underlying physics. The process is elegant in its simplicity and effectiveness, relying on fundamental electromagnetic principles.

Electromagnetic Induction

An induction furnace contains a water-cooled copper coil. When a medium-frequency alternating current is applied to this coil, it creates a powerful and rapidly changing magnetic field.

When conductive material, like scrap metal or ingots, is placed inside the coil, this magnetic field induces strong electrical currents (called eddy currents) within the metal itself.

Rapid and Uniform Heating

These eddy currents encounter electrical resistance as they flow through the metal, which generates intense heat. This method, known as Joule heating, is incredibly efficient because the heat is generated directly within the material to be melted.

This process ensures fast, uniform melting and allows for precise control over the final temperature of the molten bath. The magnetic field also creates a stirring action, which helps to homogenize the alloy and temperature.

The Complete Melting & Casting Cycle

The furnace is just one part of a multi-stage process.

- Charging: The furnace crucible is loaded with the metal to be melted, which can be in the form of scrap, ingots, or recycled material.

- Melting: Power is applied, and the charge melts rapidly. Alloying elements can be added with precision due to the controlled environment.

- Pouring: Once the metal reaches the target temperature and composition, the furnace is tilted to pour the molten metal into a ladle or directly into molds.

- Solidification & Finishing: The metal cools and solidifies within the mold, creating the cast part, which is then removed for any final trimming or machining.

Key Advantages in Modern Foundries

The widespread adoption of this technology stems from several clear and compelling advantages over traditional fuel-fired or cupola furnaces.

Unmatched Precision and Control

The ability to precisely manage power input allows for exact temperature control. This is critical for meeting the tight specifications of modern alloys and preventing the loss of valuable alloying elements through overheating.

Superior Efficiency

Because heat is generated directly within the metal, energy transfer is highly efficient, leading to faster melt times and lower energy consumption per ton of metal. There is minimal wasted heat radiated to the surrounding environment.

Versatility Across Metals

A single medium frequency furnace can be used to melt a wide range of metals. This includes steel, stainless steel, iron, copper, brass, aluminum, and various other non-ferrous alloys, providing foundries with significant operational flexibility.

Enhanced Casting Quality

The clean melting process and electromagnetic stirring action minimize contamination and ensure a homogenous mixture. This results in castings with fewer defects, improved dimensional accuracy, and a better surface finish.

Understanding the Trade-offs

While highly effective, induction melting is not a universal solution. Acknowledging its specific operational context is key to making an informed decision.

Initial Capital Investment

The advanced technology, particularly the IGBT-based power supply and control systems, typically requires a higher upfront capital investment compared to more traditional furnace types.

Maintenance and Skill Requirements

The sophisticated electronics and water-cooling systems demand a higher level of technical skill for maintenance and troubleshooting. Operators also require training to leverage the furnace's control capabilities effectively.

Scale of Operation

Medium frequency furnaces excel in producing small to medium-sized batches where precision and flexibility are paramount. For continuous, high-tonnage bulk melting of a single material (like in a primary steel mill), other technologies like electric arc furnaces may be more economical.

Making the Right Choice for Your Operation

The decision to use a medium frequency induction furnace should be driven by your specific manufacturing goals.

- If your primary focus is high-quality, complex castings: This technology offers the precise temperature and alloy control necessary to minimize defects and meet stringent specifications.

- If your primary focus is operational efficiency and sustainability: The high energy efficiency, rapid melting, and reduced material waste directly lower operating costs and support green manufacturing goals.

- If your primary focus is material versatility: The ability to efficiently melt a wide range of different metals in the same furnace makes it ideal for jobbing foundries and diverse product lines.

Ultimately, the medium frequency induction furnace has become a cornerstone of modern metal casting by enabling foundries to produce better products, faster, and with greater control.

Summary Table:

| Key Feature | Benefit for Melting & Casting |

|---|---|

| Electromagnetic Induction | Non-contact, internal heating for rapid, uniform melting |

| Precise Temperature Control | Ensures alloy integrity and minimizes defects in final castings |

| High Energy Efficiency | Faster melt times and lower operational costs per ton |

| Electromagnetic Stirring | Creates a homogenous melt for consistent casting quality |

| Material Versatility | Capable of melting steel, iron, copper, aluminum, and more |

Ready to enhance your metal casting operations with precision melting technology?

KINTEK's advanced medium frequency induction furnace solutions are engineered to deliver the control, efficiency, and versatility your foundry needs. Leveraging our exceptional R&D and in-house manufacturing, we provide robust furnaces tailored to your specific requirements, whether you focus on high-quality complex castings, operational efficiency, or material versatility.

Contact KINTEK today to discuss how our technology can help you achieve superior casting quality and reduce your operating costs.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification