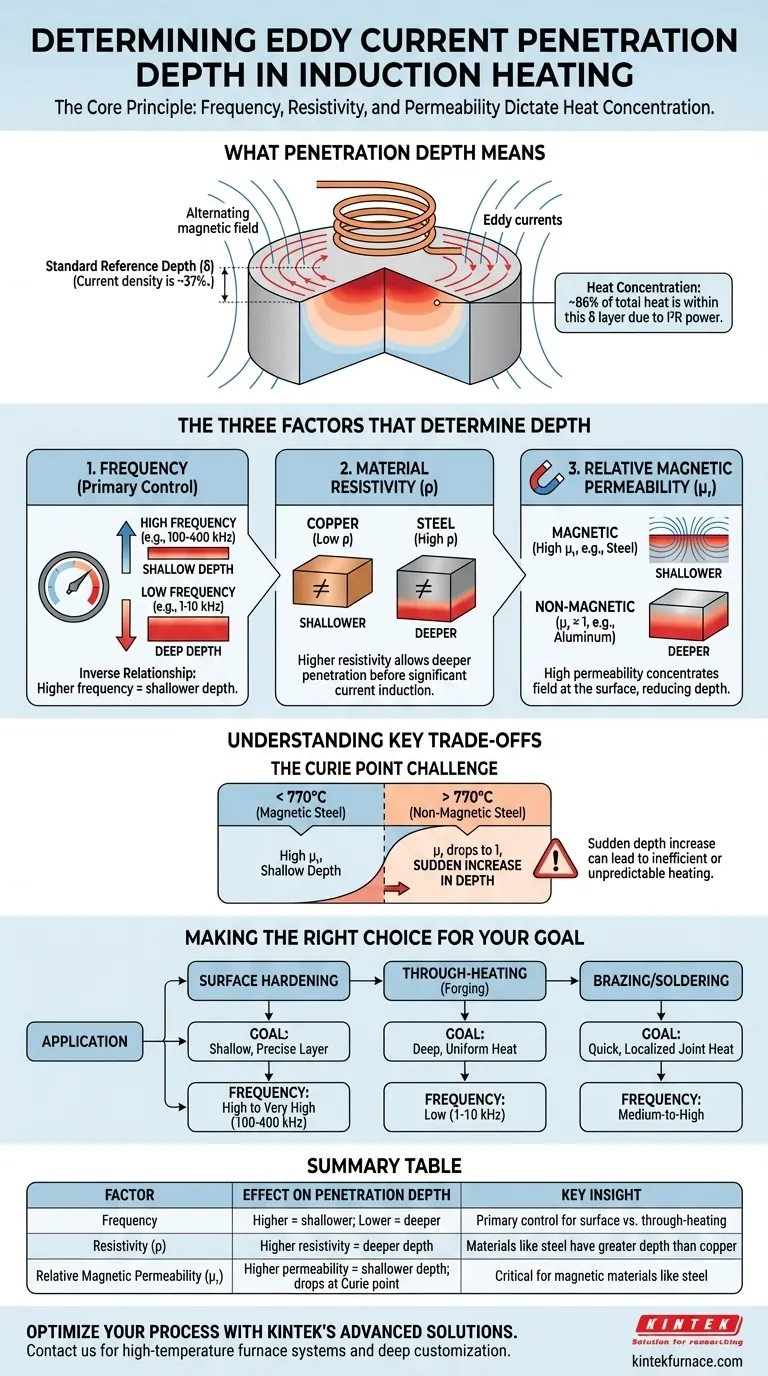

At its core, the penetration depth of eddy currents in induction heating is determined by three key factors: the frequency of the alternating magnetic field, the electrical resistivity of the material being heated, and the material's relative magnetic permeability. These variables dictate how far induced currents penetrate beneath the surface of a workpiece. A higher frequency, for instance, will always result in a shallower heating depth.

The central principle to grasp is that "penetration depth" is not a hard line, but an exponential decay. True control in induction heating comes from understanding how to manipulate frequency to concentrate the majority of the heat energy precisely where it is needed for a given process.

What "Penation Depth" Actually Means

The term can be misleading if taken too literally. It's crucial to understand it as a region of concentration rather than a simple physical depth.

The Skin Effect in Action

In induction heating, the alternating magnetic field from the coil induces eddy currents primarily at the surface of the workpiece. This phenomenon is known as the skin effect.

The density of these currents is highest at the surface and decays exponentially as you move deeper into the material.

The Standard Reference Depth (δ)

Engineers define the penetration depth (often denoted by the Greek letter delta, δ) as the depth at which the eddy current density has fallen to approximately 37% of its value at the surface.

This is the standard engineering and physics definition, providing a consistent metric for calculation and comparison.

Where the Heat is Concentrated

From a practical heating perspective, the most important fact is that roughly 86% of the total heat generated by the eddy currents is concentrated within this single layer of reference depth (δ).

This happens because heating power is proportional to the square of the current (I²R). Therefore, the power is far more concentrated near the surface than the current density itself.

The Three Factors That Determine Depth

You can control the heating profile by understanding and manipulating the following three variables.

1. Frequency (The Primary Control)

Frequency is the most powerful and common tool for controlling penetration depth. The relationship is simple and inverse:

- High Frequency = Shallow Penetration Depth

- Low Frequency = Deep Penetration Depth

This is why processes like surface hardening use very high frequencies (100 kHz to 400 kHz+) to heat only a thin outer layer, while applications like through-heating for forging use low frequencies (1 kHz to 10 kHz) to heat the entire workpiece uniformly.

2. Material Resistivity (ρ)

Resistivity is a material's inherent resistance to electrical current flow. A higher resistivity allows the magnetic field to penetrate deeper before it can induce significant eddy currents.

Therefore, materials with higher resistivity will have a deeper penetration depth, all other factors being equal. For example, steel has a higher resistivity than copper, so the penetration depth in steel will be greater than in copper at the same frequency.

3. Relative Magnetic Permeability (μr)

Magnetic permeability is a measure of a material's ability to support the formation of a magnetic field. This factor has a dramatic impact, but primarily applies to magnetic materials like carbon steel, iron, and nickel.

A high magnetic permeability significantly reduces the penetration depth by concentrating the magnetic field at the very surface. Non-magnetic materials like aluminum, copper, and austenitic stainless steel have a permeability of 1.

Understanding the Key Trade-offs

Controlling depth is a balancing act, and misunderstanding these principles can lead to process failure.

The Curie Point Challenge

For magnetic materials like steel, permeability is not constant. When heated above a specific temperature—the Curie point (around 770°C / 1420°F for steel)—the material becomes non-magnetic.

At this point, its relative permeability drops from a high value (potentially several hundred) down to 1. This causes the penetration depth to suddenly and dramatically increase, which can lead to inefficient heating or unpredictable results if the power supply cannot adapt.

Choosing the Wrong Depth

The consequences of a mismatch between frequency and the desired outcome are significant.

- For surface hardening: Using a frequency that is too low results in a heating depth that is too great. This can soften the core of the component, ruin its mechanical properties, and waste energy.

- For through-heating: Using a frequency that is too high will superheat the surface while leaving the core cold, leading to thermal stress, cracking, or an incomplete process.

Making the Right Choice for Your Goal

Your application dictates the ideal penetration depth, and therefore the frequency you should choose.

- If your primary focus is surface hardening or case hardening: Use high to very high frequencies (e.g., 100-400 kHz) to create a shallow, precise, and hard outer layer while preserving the ductile core.

- If your primary focus is through-heating for forging or forming: Use low frequencies (e.g., 1-10 kHz) to ensure the heat penetrates deeply and uniformly throughout the entire mass of the workpiece.

- If your primary focus is brazing or soldering: Use medium-to-high frequencies that heat the joint area quickly without excessive heat spreading to adjacent, sensitive components.

- If you are heating magnetic steel past its Curie point: Ensure your system is designed to handle the sudden change in load as the penetration depth increases mid-process.

Mastering induction heating is achieved by deliberately controlling where your energy is focused.

Summary Table:

| Factor | Effect on Penetration Depth | Key Insight |

|---|---|---|

| Frequency | Higher frequency = shallower depth; lower frequency = deeper depth | Primary control for surface vs. through-heating |

| Resistivity (ρ) | Higher resistivity = deeper depth | Materials like steel have greater depth than copper |

| Relative Magnetic Permeability (μr) | Higher permeability = shallower depth; drops at Curie point | Critical for magnetic materials like steel |

Optimize your induction heating processes with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise matching to your unique experimental needs, enhancing efficiency and results. Contact us today to discuss how we can support your thermal processing goals!

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What are the advantages of ceramic/metal composites produced using a vacuum press? Achieve Superior Strength and Durability

- How does the use of vacuum in hot-pressing affect the material processing? Achieve Denser, Purer, and Stronger Materials

- What are some specific applications of vacuum hot press furnaces? Unlock Advanced Material Fabrication

- What is the process of vacuum hot pressing? Achieve Ultra-Dense, High-Purity Materials

- What are the advantages of hot pressing? Achieve Maximum Density and Superior Material Properties