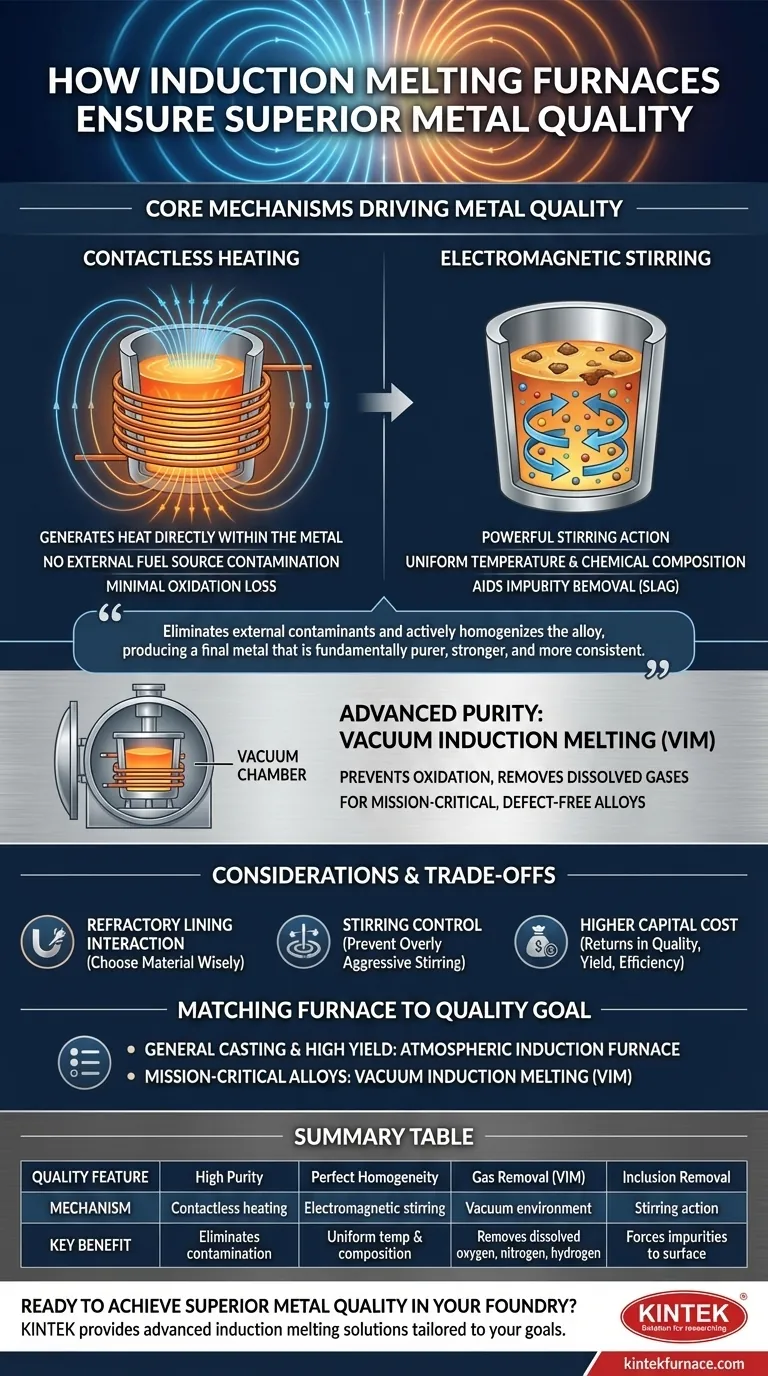

At its core, an induction melting furnace ensures superior metal quality through two fundamental principles: contactless heating and electromagnetic stirring. The process generates heat directly within the metal itself, preventing contamination from external fuel sources, while the inherent stirring action of the magnetic field guarantees a perfectly uniform temperature and chemical composition throughout the melt.

The true advantage of induction melting lies in its precise control over the melt environment. By eliminating external contaminants and actively homogenizing the alloy, the process produces a final metal that is fundamentally purer, stronger, and more consistent than what is achievable with traditional methods.

The Core Mechanisms Driving Metal Quality

To understand why induction melting is superior, we must look beyond simply heating the metal and examine the physics at play. The quality improvements are not accidental; they are a direct result of the process's core mechanisms.

Contactless Heating: The Foundation of Purity

Induction heating works by using a powerful alternating magnetic field to induce electrical currents (eddy currents) directly within the conductive metal charge. The metal's natural resistance to these currents generates precise and rapid heat from the inside out.

This method completely avoids the primary source of contamination found in traditional furnaces: the combustion of fuel. There are no byproducts like sulfur or excess carbon introduced into the melt, resulting in a cleaner base metal. This also means minimal oxidation loss, as the melting is so rapid, especially when processing scrap.

Electromagnetic Stirring: For Perfect Homogeneity

The same magnetic forces that generate heat also create a powerful stirring action within the molten bath. This electromagnetic stirring is critical for several reasons.

First, it ensures a uniform temperature distribution, eliminating hot spots that can damage alloying elements or the furnace lining. Second, it guarantees a homogeneous chemical composition, as alloying additions are mixed in thoroughly and evenly, preventing segregation and inconsistent properties in the final casting.

Finally, this stirring action helps non-metallic inclusions and impurities (known as slag or dross) to float to the surface, where they can be easily skimmed off before pouring.

Advanced Purity with Vacuum Induction Melting (VIM)

For the most demanding applications, such as aerospace or medical components, an induction furnace can be operated within a vacuum chamber. This process, known as Vacuum Induction Melting (VIM), takes quality to the highest possible level.

The vacuum environment prevents any possibility of oxidation. More importantly, it actively pulls dissolved gases like oxygen, nitrogen, and hydrogen out of the molten metal. The removal of these gases is critical for preventing porosity and achieving the superior mechanical properties required for mission-critical parts.

Understanding the Trade-offs and Considerations

While highly effective, induction technology is not without its operational nuances. Acknowledging these factors is key to maximizing its benefits.

Refractory Lining Interaction

Although the heat source is contactless, the molten metal is still held in a crucible made of refractory material. An improper refractory choice or a poorly maintained lining can become a source of non-metallic inclusions in the melt. The vigorous stirring can accelerate wear on a low-quality lining, so material compatibility is critical.

Stirring Can Be Too Aggressive

The powerful stirring action is usually a significant benefit, but it must be controlled. For certain alloys sensitive to gas pickup from the atmosphere, an overly vigorous stir can break the surface of the melt and increase exposure. Modern systems allow for precise control over power and frequency to manage the intensity of the stir.

Higher Initial Capital Cost

Induction furnace systems typically represent a higher upfront investment compared to traditional fuel-fired furnaces. The return on this investment is realized through higher metal quality, greater material yield (less loss to oxidation), faster production cycles, and a cleaner, safer operating environment.

Matching the Furnace to Your Quality Goal

The right technology choice depends entirely on the required quality level of your final product.

- If your primary focus is high-purity and consistent general casting: A standard atmospheric induction furnace delivers an exceptional balance of quality, speed, and operational cost.

- If your primary focus is maximizing yield from valuable scrap: The rapid, low-oxidation melting of an induction furnace is ideal for preserving material that would otherwise be lost in a slower, fuel-fired process.

- If your primary focus is producing mission-critical, high-performance alloys: A Vacuum Induction Melting (VIM) furnace is non-negotiable for its ability to remove dissolved gases and create the ultra-pure, defect-free metal these applications require.

By understanding these core principles, you can confidently leverage induction technology to deliver the precise metal quality your application demands.

Summary Table:

| Quality Feature | Mechanism | Key Benefit |

|---|---|---|

| High Purity | Contactless heating (no fuel combustion) | Eliminates contamination from sulfur, carbon, etc. |

| Perfect Homogeneity | Electromagnetic stirring | Uniform temperature & chemical composition |

| Gas Removal (VIM) | Vacuum environment | Removes dissolved oxygen, nitrogen, hydrogen |

| Inclusion Removal | Stirring action | Forces impurities to surface for easy skimming |

Ready to Achieve Superior Metal Quality in Your Foundry?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides foundries and metal producers with advanced induction melting solutions tailored to your specific quality goals. Whether you need the high-purity consistency of an atmospheric furnace or the mission-critical performance of a Vacuum Induction Melting (VIM) system, our deep customization capabilities ensure your furnace precisely meets the unique requirements of your alloys and processes.

Our product line includes:

- Atmospheric Induction Furnaces for high-purity general casting and maximum scrap yield.

- Vacuum Induction Melting (VIM) Furnaces for producing ultra-pure, gas-free superalloys for aerospace and medical components.

Contact us today to discuss how our technology can help you produce cleaner, stronger, and more consistent metal.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control