At its core, the precision of induction heating comes from its unique ability to generate heat directly inside the material itself. Unlike conventional methods that heat a part from the outside-in using ambient heat, induction uses a non-contact electromagnetic field to induce an electrical current within the conductive workpiece, creating precise, rapid, and localized heat exactly where it is needed.

The fundamental difference is this: traditional furnaces heat the environment to heat the part, while induction uses a magnetic field to make the part heat itself from within. This shift from external to internal heat generation is the source of its unparalleled control.

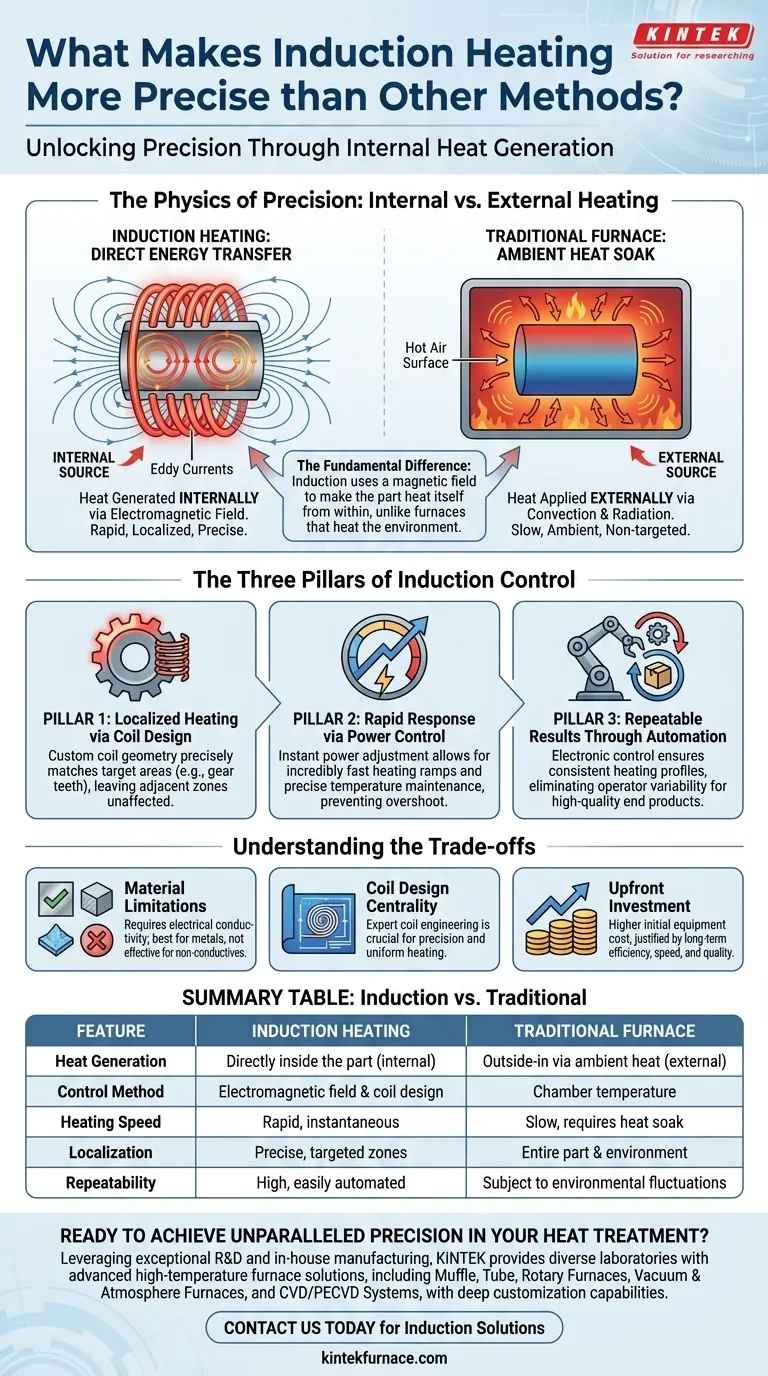

The Physics of Precision: Internal vs. External Heating

To truly grasp why induction is more precise, you must understand the difference in how heat is delivered. It's a contrast between targeted energy transfer and ambient heat soak.

How Induction Heating Works: Direct Energy Transfer

Induction heating uses an alternating current passed through a precisely engineered induction coil. This creates a powerful, oscillating magnetic field around the coil.

When a conductive material (like a metal part) is placed within this field, the field induces circular electrical currents inside the part. These currents, known as eddy currents, flow against the material's electrical resistance, generating intense and instantaneous heat.

The heat is generated inside the part, not applied to its surface. Heat then transfers from the inside out via thermal conduction.

The Conventional Approach: Convection and Radiation

Traditional gas or electric furnaces operate on entirely different principles. They heat the internal chamber of the furnace to a very high temperature.

Heat is then transferred to the workpiece slowly through convection (the movement of hot air) and radiation (infrared energy emitted by the hot furnace walls). The part's surface heats up first, and the heat must then soak into the core.

The Critical Difference: Targeted Energy vs. Ambient Heat

This difference is like the difference between a surgical laser and a floodlight. A furnace is a floodlight, bathing the entire environment—and everything in it—in undirected heat.

Induction is a laser, delivering energy only to a specific, targeted zone defined by the magnetic field, leaving adjacent areas unaffected.

The Three Pillars of Induction Control

The precision of induction heating isn't based on a single factor, but on three interlocking elements that provide complete control over the process.

Pillar 1: Localized Heating via Coil Design

The shape and geometry of the induction coil are critical. The magnetic field is strongest closest to the coil, allowing engineers to design coils that precisely match the area of the part that needs to be heated.

This makes it possible to harden just the teeth of a gear, anneal only the tip of a surgical tool, or braze a joint without affecting the rest of the assembly. This level of spatial control is impossible with a furnace.

Pillar 2: Rapid Response via Power Control

The heat generated is directly proportional to the power supplied to the coil. Modern solid-state power supplies can adjust this power level instantly and with extreme accuracy.

This allows for incredibly fast heating ramps and precise temperature maintenance. The process can be started or stopped in an instant, preventing the thermal "overshoot" common in furnaces, which must cool down slowly.

Pillar 3: Repeatable Results Through Automation

Because the process is controlled electronically, induction heating is perfectly suited for automation. Once a heating profile (power level, time, and coil position) is established, it can be repeated thousands of times with virtually no deviation.

This eliminates the operator variability and environmental fluctuations that can affect the consistency of furnace-based processes, leading to higher quality end products.

Understanding the Trade-offs

While powerful, induction heating is not a universal solution. Its precision comes with specific requirements.

Material Limitations

Induction's primary mechanism relies on electrical conductivity. Therefore, it works best on metals and other conductive materials like graphite. It is not an effective method for heating non-conductive materials like most ceramics or plastics.

The Centrality of Coil Design

The adage "the coil is key" is true. Achieving precision for a complex part geometry requires expert coil design and fabrication, which can be a significant engineering task. A poorly designed coil will lead to inefficient and uneven heating.

Upfront Equipment Investment

The initial cost of an induction heating system, including the power supply and custom coils, is often higher than that of a conventional furnace. This investment is typically justified by higher throughput, lower energy costs, and improved product quality over time.

When to Choose Induction Heating

The decision to use induction should be based on your specific technical and business goals.

- If your primary focus is high-volume, repeatable manufacturing: Induction is ideal due to its unparalleled speed, consistency, and potential for automation.

- If your primary focus is heat-treating specific sections of a part: Induction's localized heating is technically superior to any furnace-based method for applications like case hardening or tempering.

- If your primary focus is process purity and control: The non-contact nature of induction eliminates contamination risks and is perfect for processing in controlled atmospheres like a vacuum or inert gas.

- If your primary focus is on simple bulk heating of various materials on a limited budget: A conventional furnace may be a more practical starting point.

By understanding that induction's precision is born from its fundamental physics, you can make a truly informed decision for your application.

Summary Table:

| Feature | Induction Heating | Traditional Furnace |

|---|---|---|

| Heat Generation | Directly inside the part (internal) | Outside-in via ambient heat (external) |

| Control Method | Electromagnetic field & coil design | Chamber temperature |

| Heating Speed | Rapid, instantaneous | Slow, requires heat soak |

| Localization | Precise, targeted zones | Entire part and environment |

| Repeatability | High, easily automated | Subject to environmental fluctuations |

Ready to achieve unparalleled precision in your heat treatment process?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Contact us today to discuss how our induction heating solutions can enhance your manufacturing consistency, speed, and control. ➡️ Get in touch via our Contact Form

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

People Also Ask

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance