At its core, Vacuum Induction Melting (VIM) is a highly controlled metallurgical process for melting metals and creating alloys within a high-vacuum chamber. Its primary purpose is to produce materials of exceptional purity and precise chemical composition. By eliminating atmospheric gases, VIM prevents contamination and removes dissolved impurities, which is essential for creating the superalloys and specialty steels used in the most demanding applications.

The true value of VIM isn't just melting metal; it's about achieving ultimate control over the material's chemistry. By removing the atmosphere from the equation, VIM prevents unwanted reactions and purifies the melt, creating the foundation for alloys with superior strength, cleanliness, and reliability.

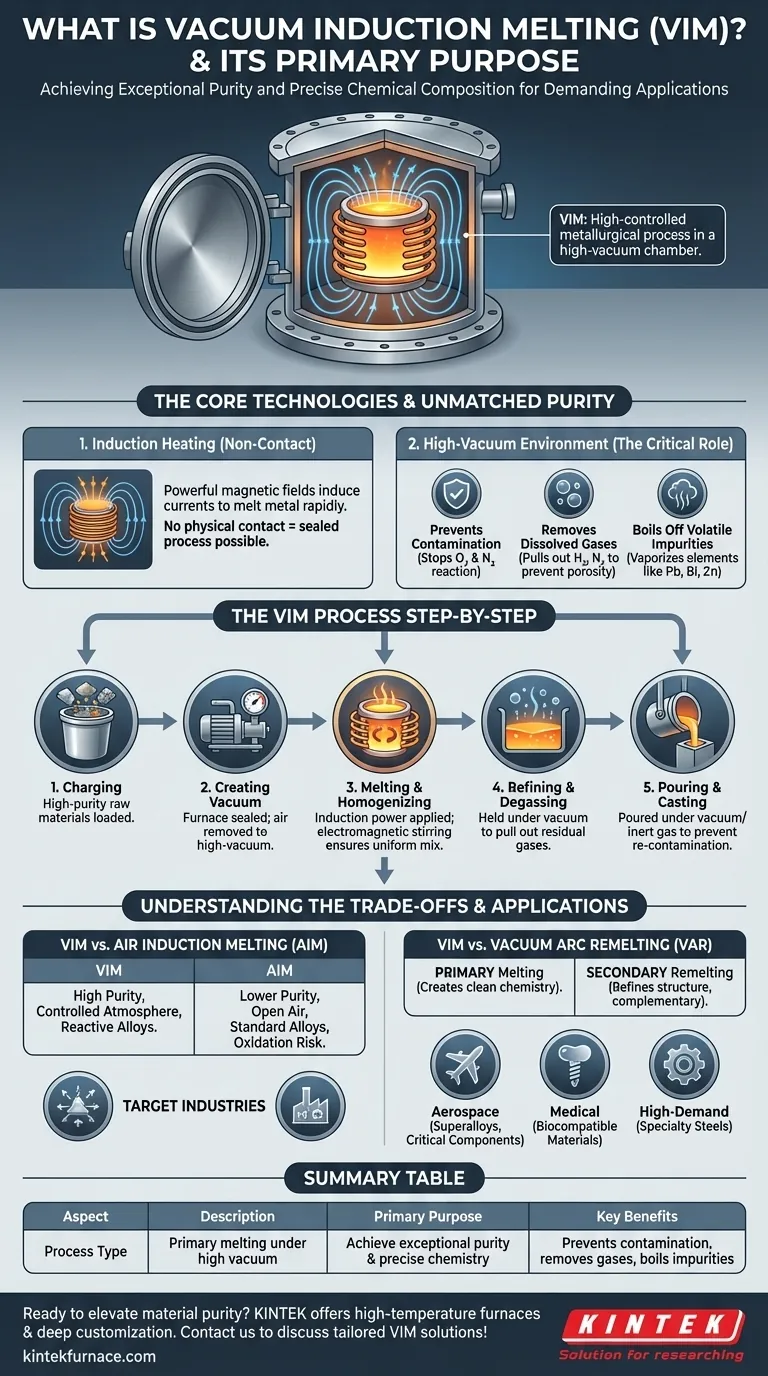

How VIM Achieves Unmatched Purity

The effectiveness of VIM comes from the combination of two core technologies: induction heating and a high-vacuum environment. Each plays a distinct and critical role.

The Principle of Induction Heating

Induction melting uses powerful, alternating magnetic fields generated by an electrical coil. This field induces strong electrical currents directly within the metal charge itself, causing it to heat up and melt rapidly and efficiently.

Because the heating is accomplished through magnetic fields, there is no physical contact between the heating source (the coil) and the metal. This isolation is what makes it possible to enclose the entire process within a sealed vacuum chamber.

The Critical Role of the Vacuum

Creating a vacuum is the defining feature of the VIM process. Removing the air from the chamber accomplishes three essential refining actions simultaneously.

First, it prevents atmospheric contamination. The oxygen and nitrogen in the air cannot react with the molten metal, preventing the formation of oxides and nitrides that compromise an alloy's integrity.

Second, it removes dissolved gases. Molten metals readily absorb gases like hydrogen and nitrogen, which can cause porosity and embrittlement when the metal solidifies. The vacuum effectively pulls these dissolved gases out of the liquid melt.

Third, it boils off volatile impurities. Elements with a high vapor pressure (like lead, bismuth, or zinc) will vaporize under vacuum at high temperatures and be drawn out by the vacuum pumps, further purifying the base metal.

Precision Control Over Alloying

With the base metal melted in a completely controlled environment, alloying elements can be added with extreme precision. This ensures the final chemical composition is exactly what is required, without the uncertainty of reactions with atmospheric gases.

The VIM Process Step-by-Step

A typical VIM cycle follows a logical and tightly controlled sequence.

Charging the Furnace

High-purity raw materials, selected for their known composition, are loaded into a ceramic crucible inside the furnace.

Creating the Vacuum

The furnace is sealed shut, and a system of powerful pumps removes the air until a specific high-vacuum level is reached.

Melting and Homogenizing

Power is applied to the induction coil, melting the charge. The electromagnetic forces generated by the coil also create a natural stirring action within the molten bath, which ensures all elements are uniformly mixed and the melt is homogenous.

Refining and Degassing

The molten metal is held under vacuum for a period of time. During this stage, the vacuum continues to pull out residual gases and volatile impurities, refining the chemistry of the melt.

Pouring and Casting

Finally, the furnace is tilted to pour the clean, molten metal into molds. This is also done under vacuum or in a controlled inert gas atmosphere (like argon) to prevent any re-contamination before the metal solidifies.

Understanding the Trade-offs

VIM is an advanced process, and its use implies a specific set of priorities. It is not always the necessary or most economical choice.

VIM vs. Air Induction Melting (AIM)

AIM is a much simpler and less expensive process where metal is melted via induction in the open air. While effective for many standard alloys, it offers no protection from oxidation or gas pickup. VIM is chosen when the alloy is highly reactive or when the final application cannot tolerate the impurities introduced by AIM.

VIM vs. Vacuum Arc Remelting (VAR)

This is a key distinction. VIM is a primary melting process used to create a clean chemical composition. VAR is a secondary remelting process used to perfect the physical structure of an already-clean alloy.

Often, an ingot or electrode is first produced via VIM and then used as the input material for a VAR furnace. The VAR process refines the grain structure and removes non-metallic inclusions, further enhancing properties like fatigue life. The two processes are complementary, not interchangeable.

When to Specify Vacuum Induction Melting

Choosing the right melting process depends entirely on the performance requirements of the final product.

- If your primary focus is creating ultra-high-purity master alloys or materials sensitive to oxygen and nitrogen: VIM is the essential first step for controlling chemical composition at the atomic level.

- If your primary focus is maximizing mechanical properties like fatigue life and toughness in critical aerospace or medical components: VIM is often used as the precursor to a secondary remelting process like VAR to achieve the cleanest possible material with a refined solid structure.

- If your primary focus is cost-effective production of standard alloys not requiring extreme purity: A simpler process like Air Induction Melting (AIM) is likely a more suitable and economical choice.

Ultimately, choosing VIM is a strategic decision to prioritize material purity and predictable performance above all else.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process Type | Primary melting under high vacuum |

| Primary Purpose | Achieve exceptional purity and precise chemical composition |

| Key Benefits | Prevents contamination, removes dissolved gases, boils off volatile impurities |

| Common Applications | Superalloys, specialty steels for aerospace, medical, and high-demand industries |

| Comparison | VIM vs. Air Induction Melting (less pure) and Vacuum Arc Remelting (complementary secondary process) |

Ready to elevate your material purity with advanced vacuum induction melting solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs. Contact us today to discuss how our tailored solutions can enhance your alloy production and drive innovation in your lab!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys