The primary advantage of a Vacuum Induction Melting (VIM) furnace is its ability to create exceptionally pure, high-performance metals and alloys. By melting materials in a controlled vacuum, a VIM furnace eliminates atmospheric contamination, prevents unwanted chemical reactions like oxidation, and allows for precise control over the final alloy composition, something an ordinary open furnace cannot achieve.

An ordinary furnace exposes molten metal to the open air, leading to impurities and unpredictable reactions. A Vacuum Induction Melting furnace creates a pristine, controlled environment, giving you absolute authority over the material's chemistry and final properties.

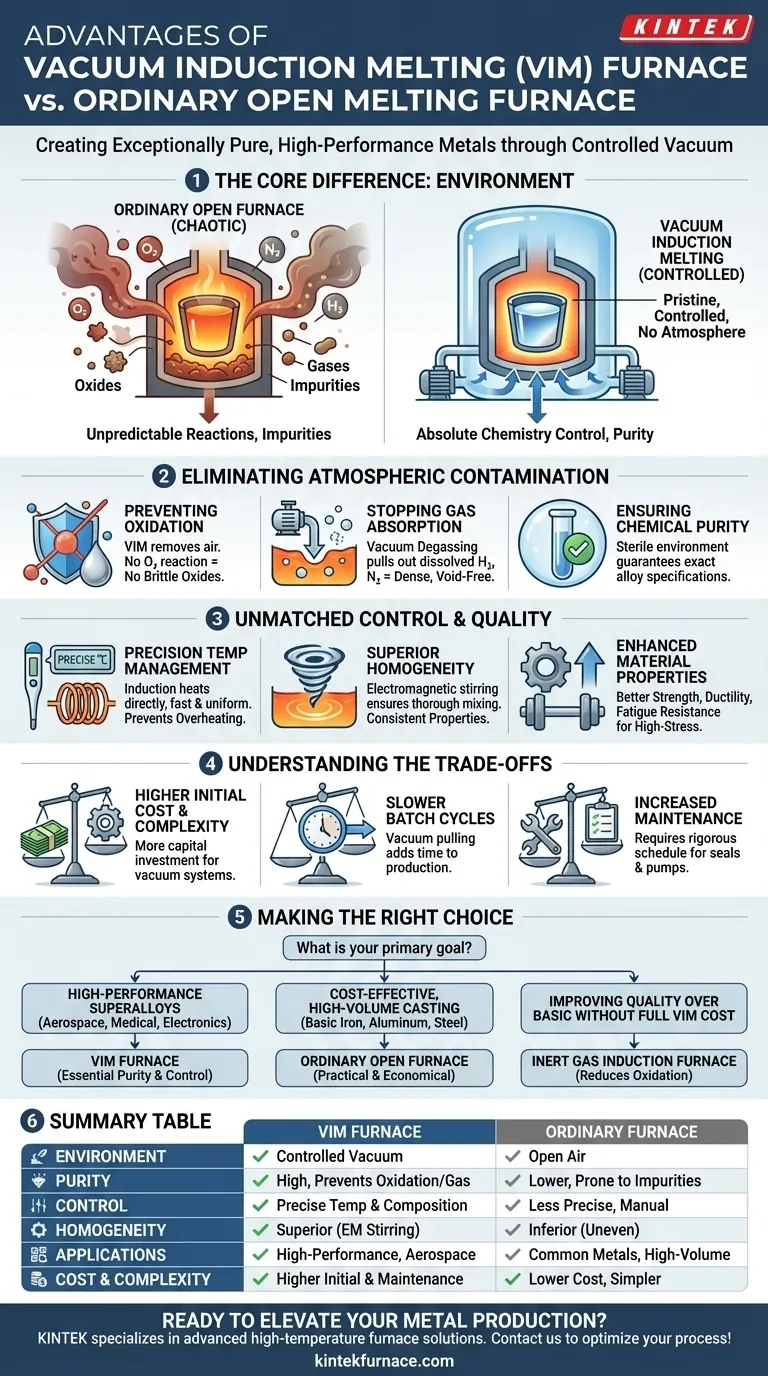

The Core Advantage: Eliminating Atmospheric Contamination

The fundamental difference between these two technologies is the environment. An open furnace is chaotic, while a vacuum furnace is controlled. This control directly prevents the three main sources of atmospheric contamination.

Preventing Oxidation

In an open furnace, ambient oxygen aggressively reacts with hot, molten metal. This reaction forms oxides—brittle impurities that degrade the metal's strength and performance.

A VIM furnace physically removes the air before melting begins. By operating in a vacuum, there is virtually no oxygen available to react with the melt, ensuring the metal remains in its pure, elemental form.

Stopping Unwanted Gas Absorption

Gases like hydrogen and nitrogen, present in the atmosphere, readily dissolve into molten metal. As the metal cools and solidifies, these trapped gases can form bubbles, leading to porosity and brittleness.

The vacuum environment not only prevents these gases from entering the melt but can also pull out dissolved gases that were already present in the raw material. This process, known as vacuum degassing, is critical for creating dense, void-free components.

Ensuring Chemical Purity

For advanced applications, even trace amounts of contamination can be catastrophic. An open furnace introduces countless variables from the surrounding air.

A VIM furnace provides a sterile environment where the only elements present are the ones you intentionally add. This guarantees that the final alloy meets exact chemical specifications every time.

Achieving Unmatched Control and Quality

Beyond purity, the combination of a vacuum and induction heating provides a level of process control that directly translates into higher-quality materials.

Precision Temperature Management

Induction heating generates heat directly within the metal itself, allowing for extremely fast, uniform, and precise temperature control. This is far superior to the indirect and often uneven heating of a flame-based open furnace.

This precision prevents the overheating of the melt, which can cause valuable, volatile alloying elements to boil off and be lost.

Superior Homogeneity

The electromagnetic field generated by the induction coil creates a natural stirring effect within the molten bath. This constant motion ensures all alloying elements are thoroughly mixed.

The result is a perfectly homogeneous alloy, where the material properties are consistent throughout the entire casting. An open furnace relies on manual stirring, which is far less effective.

Enhanced Material Properties

The combination of high purity, low gas content, and perfect homogeneity results in alloys with superior mechanical properties. Metals produced in a VIM furnace exhibit significantly better strength, ductility, and fatigue resistance, making them essential for high-stress applications.

Understanding the Trade-offs

While technologically superior, a VIM furnace is not always the necessary choice. Understanding its limitations is key to making a sound investment.

Higher Initial Cost and Complexity

VIM systems are sophisticated machines. The vacuum chamber, high-power pumps, and advanced control systems result in a significantly higher capital investment compared to a simple open furnace.

Slower Batch Cycles

The process of pulling a vacuum before each melt adds significant time to the production cycle. For high-volume production of non-critical metals, the throughput of an open furnace is much higher.

Increased Maintenance Requirements

The complex nature of a VIM furnace, particularly its vacuum seals, pumps, and instrumentation, demands a more rigorous and specialized maintenance schedule.

Making the Right Choice for Your Application

The decision ultimately depends on the material you are producing and its end-use requirements.

- If your primary focus is producing high-performance superalloys or reactive metals (like titanium) for aerospace, medical, or electronics: A VIM furnace is non-negotiable; its purity and control are essential.

- If your primary focus is cost-effective, high-volume casting of common metals (like basic iron, aluminum, or standard steel): An ordinary open furnace is almost always the more practical and economical choice.

- If your primary focus is improving quality over a basic furnace without the full cost of VIM: Consider a non-vacuum induction furnace with an inert gas cover (like argon) to reduce oxidation.

Choosing the right furnace is about matching the level of environmental control to the required purity and performance of your final product.

Summary Table:

| Aspect | Vacuum Induction Melting (VIM) Furnace | Ordinary Open Melting Furnace |

|---|---|---|

| Environment | Controlled vacuum | Open air |

| Purity | High, prevents oxidation and gas absorption | Lower, prone to impurities |

| Control | Precise temperature and alloy composition | Less precise, manual stirring |

| Homogeneity | Superior, due to electromagnetic stirring | Inferior, uneven mixing |

| Applications | High-performance alloys, aerospace, medical | Common metals, high-volume casting |

| Cost and Complexity | Higher initial cost and maintenance | Lower cost, simpler operation |

Ready to elevate your metal production with precision and purity? KINTEK specializes in advanced high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces and CVD/PECVD Systems. With our strong R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs. Whether you're in aerospace, medical, or electronics, our expertise ensures superior material quality. Contact us today to discuss how we can optimize your process!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace and Arc Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What components make up a Vacuum Induction Melting Furnace? Discover the Key Systems for Pure Metal Melting

- What industries benefit from Vacuum Induction Melting Furnaces? Unlock High-Purity Metals for Aerospace, Medical, and More

- How is operator safety ensured during the vacuum induction melting process? Discover Multi-Layered Protection for Your Lab

- What are the main applications of vacuum induction melting (VIM) furnaces? Achieve Unmatched Metal Purity for Critical Industries

- What are the key benefits of using vacuum melting furnaces? Achieve Superior Purity and Control for High-Performance Alloys