In short, inductive stirring is the natural, self-mixing action that occurs within molten metal when heated in an induction furnace. This movement is a direct result of the powerful electromagnetic forces generated by the furnace's coil, ensuring the melt is uniform in temperature and composition without any mechanical parts.

Inductive stirring is not merely a side effect; it is a fundamental metallurgical process that dictates the quality and efficiency of your melt. Understanding how to manage this force—primarily through the furnace's power and frequency—is the key to achieving consistent, high-quality results.

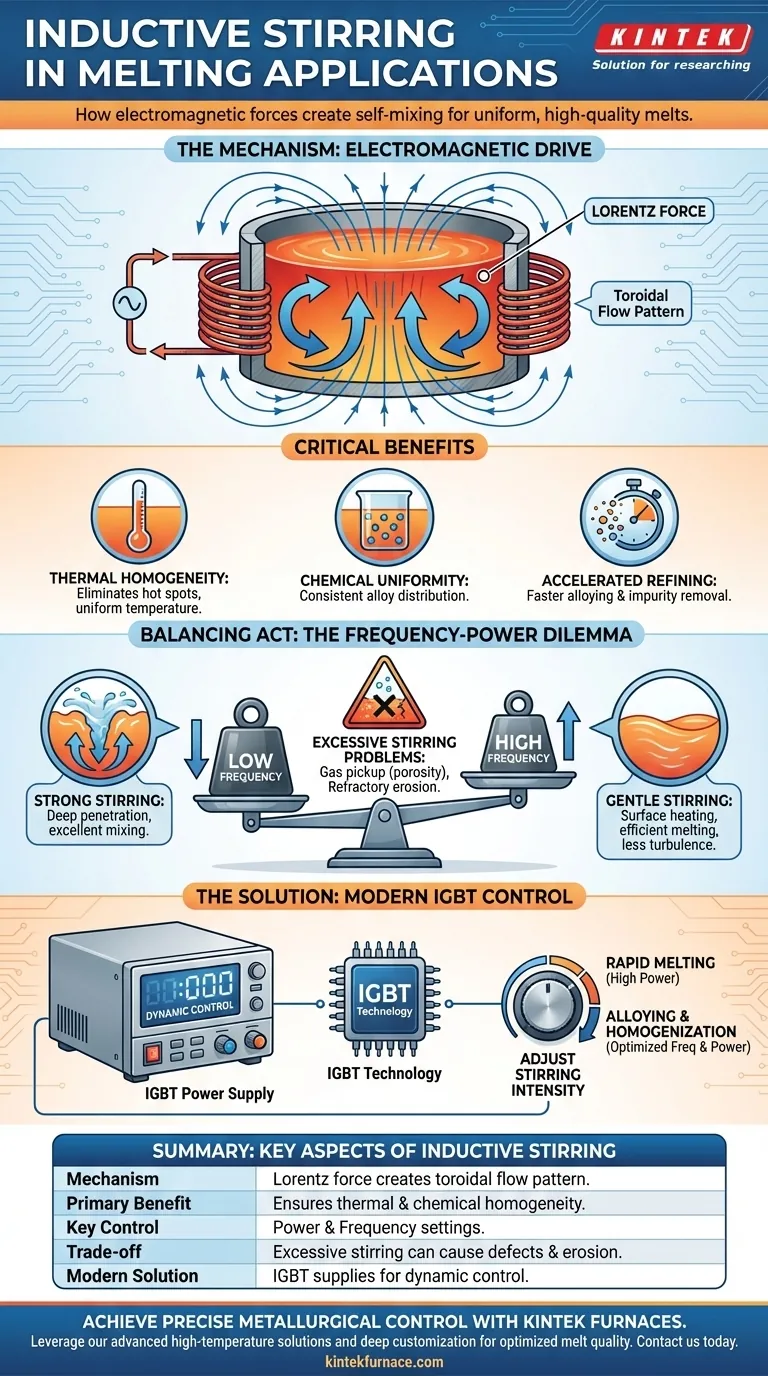

How Electromagnetic Forces Drive Stirring

The stirring action in an induction furnace is a direct consequence of fundamental physics. It is a predictable and controllable force if you understand the principles at play.

The Lorentz Force in Action

The alternating current flowing through the furnace's copper coil generates a powerful and fluctuating magnetic field. This field, in turn, induces a strong electrical current within the conductive metal charge inside the furnace.

The interaction between the coil's magnetic field and the induced current in the metal creates a powerful electromagnetic force known as the Lorentz force. This force is what physically pushes and moves the molten metal.

The Classic Flow Pattern

This force is strongest near the furnace walls, pushing the molten metal inward from the perimeter and downward from the surface. To compensate, the metal then flows upward through the center of the bath.

This creates a continuous, rolling, toroidal (donut-shaped) flow pattern. This constant circulation is the engine of inductive stirring.

Why Inductive Stirring is Critical for Melt Quality

This constant motion provides several essential benefits that are critical for modern foundry and steelmaking operations. Without it, producing high-quality metal would be significantly more difficult and less efficient.

Ensuring Thermal Homogeneity

Without stirring, the top of the molten bath would become superheated while the bottom remained cooler. Inductive stirring constantly circulates the metal, eliminating hot spots and cold zones.

This results in a uniform temperature throughout the bath, which is crucial for accurate temperature readings, predictable chemistry, and preventing damage to the furnace lining.

Achieving Chemical Uniformity

When adding alloys, they must be completely dissolved and evenly distributed to meet final specifications. Stirring is the mechanism that achieves this.

The powerful flow quickly disperses alloying elements throughout the entire melt, preventing segregation and ensuring the final cast product has a consistent and uniform chemical composition.

Accelerating Alloying and Refining

The constant motion dramatically increases the rate at which alloys dissolve into the bath. It also accelerates reactions with slag, helping to remove impurities from the metal more quickly and efficiently.

Understanding the Trade-offs

While essential, the intensity of the stir is not always beneficial. More is not always better, and controlling the stirring action is a key aspect of sophisticated melt management.

The Problem of Excessive Stirring

An overly vigorous stir can be detrimental. It increases surface turbulence, which can introduce atmospheric gases like oxygen and nitrogen into the melt, leading to porosity and defects.

Excessive stirring can also accelerate the erosion of the furnace's refractory lining, increasing maintenance costs and the risk of metal contamination.

The Frequency-Power Dilemma

The intensity of the stirring is governed by two main factors: power and frequency.

- Lower frequency current penetrates deeper into the molten bath, creating a very strong stirring action.

- Higher frequency current concentrates heat near the surface, resulting in a much gentler, less vigorous stir.

This creates a fundamental trade-off. A low frequency is excellent for mixing but can be less electrically efficient for melting, while a high frequency is highly efficient for melting small scrap but provides poor mixing for alloying.

The Role of Modern IGBT Power Supplies

This is where modern technology provides a solution. Power supplies built with Insulated Gate Bipolar Transistors (IGBTs) are high-speed switches that offer precise control over both power and frequency.

This allows operators to adjust the stirring intensity dynamically. You can use high power for rapid melting and then adjust the power or frequency to create the ideal stirring conditions for alloying and temperature homogenization, giving you the best of both worlds.

Matching Stirring Intensity to Your Goal

The ideal level of stirring depends entirely on your specific metallurgical objective. By controlling your furnace parameters, you can optimize the process for your desired outcome.

- If your primary focus is bulk melting a single material: You can favor a higher frequency for maximum electrical efficiency, as intense chemical mixing is less critical.

- If your primary focus is complex alloying or refining: A lower frequency (or a power supply with variable frequency) is superior to ensure complete and rapid homogenization of additions.

- If your primary focus is melting metals sensitive to gas pickup: You need precise control to minimize surface turbulence, often by reducing power or using a higher frequency during the final stages.

Ultimately, mastering inductive stirring transforms it from a passive phenomenon into an active and powerful tool for metallurgical control.

Summary Table:

| Key Aspect | Description |

|---|---|

| Mechanism | Lorentz force from electromagnetic fields creates a toroidal flow pattern. |

| Primary Benefit | Ensures thermal and chemical homogeneity throughout the melt. |

| Key Control Factors | Power and frequency settings of the induction furnace. |

| Trade-off | Excessive stirring can cause gas pickup and refractory erosion. |

| Modern Solution | IGBT power supplies allow for dynamic control of stirring intensity. |

Achieve precise metallurgical control in your melting operations. Inductive stirring is a powerful tool, and harnessing it effectively requires the right equipment. KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including our robust Induction Furnaces. Our strong deep customization capability ensures your furnace is precisely configured to manage stirring intensity for your specific alloys and processes—whether you need vigorous mixing for complex alloying or gentle stirring for gas-sensitive metals. Contact us today to discuss how we can optimize your melt quality and efficiency. Let's talk about your application →

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the key components of a Vacuum Induction Melting (VIM) furnace? Master High-Purity Metal Processing

- What industries benefit from Vacuum Induction Melting Furnaces? Unlock High-Purity Metals for Aerospace, Medical, and More

- How does vacuum induction melting work? Achieve Ultra-Pure, High-Performance Alloys

- What are the key features and benefits of a Vacuum Induction Melting Furnace? Achieve High-Purity Metal Production

- What components make up a Vacuum Induction Melting Furnace? Discover the Key Systems for Pure Metal Melting