In short, a Vacuum Induction Melting (VIM) furnace can reach temperatures up to 2600°C (4712°F). This capability allows it to melt not only standard steels and alloys but also highly demanding superalloys and refractory metals used in the most advanced industries. However, the extreme temperature is only one part of its function; its true value lies in creating an exceptionally pure and controlled melting environment.

The core purpose of a VIM furnace is not just to melt metal, but to refine it. By combining high-frequency induction heat with a high-vacuum environment, it produces alloys with a level of purity, compositional accuracy, and homogeneity that is unattainable with conventional air-melting techniques.

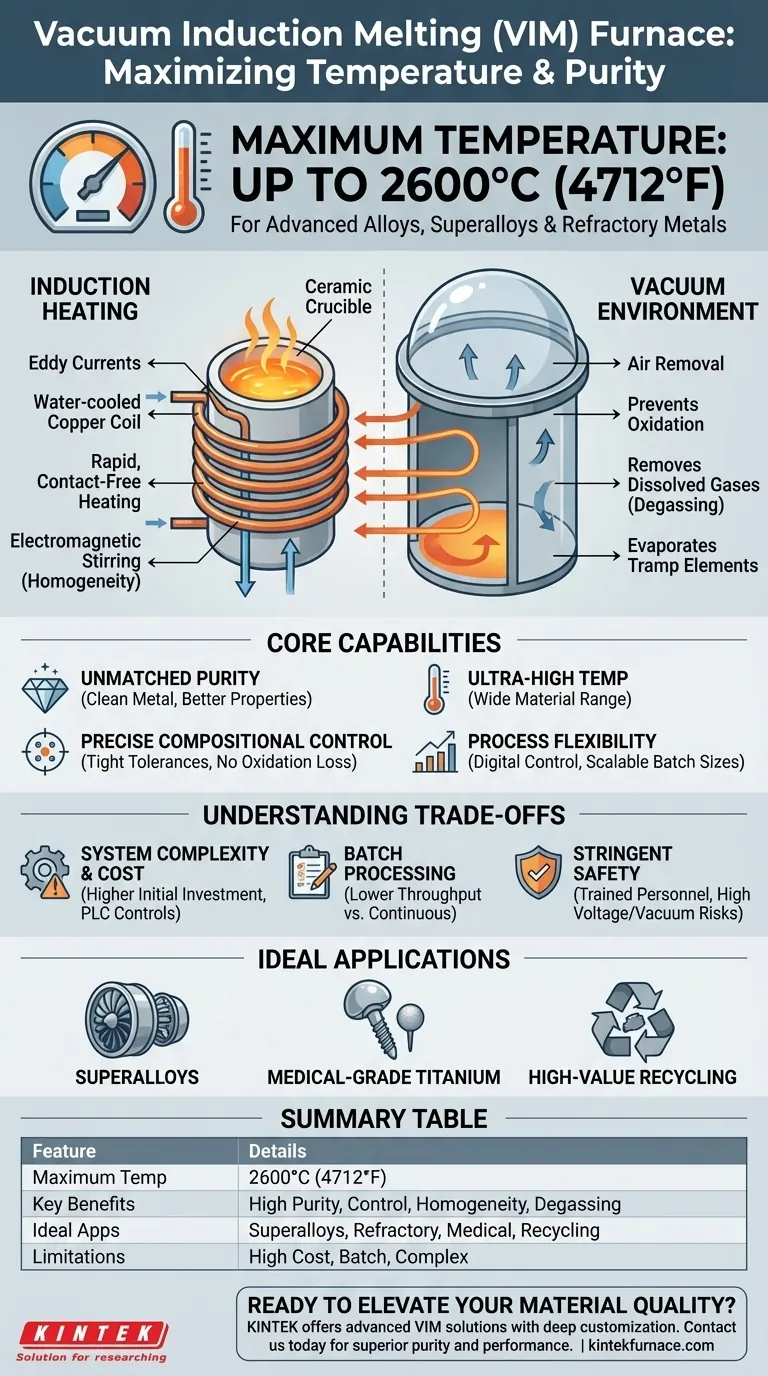

How VIM Delivers Purity and Performance

A VIM furnace is a sophisticated system designed to solve the two biggest challenges in high-performance metallurgy: contamination and inconsistency. It achieves this through the integration of a vacuum and a unique heating method.

The Principle of Induction Heating

The furnace uses a water-cooled copper coil to generate a powerful, high-frequency electromagnetic field. This field passes through the ceramic crucible and induces strong electrical eddy currents directly within the metal charge itself.

The metal’s natural electrical resistance causes it to heat up rapidly and efficiently from the inside out. This process is clean, contact-free, and provides the added benefit of electromagnetic stirring, which naturally mixes the molten bath to ensure a perfectly homogenous final product.

The Critical Role of the Vacuum

Before and during melting, a powerful vacuum system removes the air from the furnace chamber. This is fundamental to the VIM process for several key reasons.

First, it prevents oxidation. Without oxygen and nitrogen, there is no chance for unwanted oxide and nitride inclusions to form, which are common sources of defects in finished parts.

Second, the vacuum actively removes dissolved gases like hydrogen from the molten metal. This "degassing" effect is critical for preventing porosity and embrittlement, especially in materials for aerospace and medical applications.

Finally, the controlled low-pressure environment allows for the evaporation of undesirable tramp elements with high vapor pressures, further purifying the alloy.

Core Capabilities of a VIM System

The combination of these principles gives the VIM furnace a unique set of capabilities that make it indispensable for producing advanced materials.

Ultra-High Temperature Capability

The ability to reach 2600°C means VIM furnaces can process a vast range of materials, from nickel and cobalt-based superalloys to titanium and even some refractory metals.

Unmatched Purity and Cleanliness

By eliminating atmospheric contamination and actively removing impurities, VIM produces some of the "cleanest" metal available. This results in materials with superior mechanical properties, such as improved fatigue life and fracture toughness.

Precise Compositional Control

The sealed, controlled environment ensures that expensive and highly reactive alloying elements (like aluminum and titanium in superalloys) are not lost to oxidation. This allows metallurgists to achieve incredibly tight compositional tolerances, hitting the exact chemistry required for a specific performance profile.

Process Flexibility

Modern VIM systems offer precise digital control over temperature, vacuum level, and power input. They are also flexible in terms of batch size, making them suitable for everything from small-scale research and development to full-scale industrial production.

Understanding the Trade-offs

While powerful, a VIM furnace is a specialized tool with specific considerations. It is not the right choice for every melting application.

System Complexity and Cost

The need for a robust vacuum system, a medium-frequency power supply, and sophisticated PLC controls makes a VIM furnace significantly more complex and expensive than a standard air-melt induction furnace or an electric arc furnace.

Batch Processing Limitations

VIM is inherently a batch process. The cycle of loading, evacuating the chamber, melting, refining, and pouring takes time. This results in lower throughput compared to continuous or semi-continuous melting operations used for high-volume commodity metals.

Stringent Safety Protocols

Operating equipment that involves high voltage, extreme temperatures, water cooling, and vacuum systems requires highly trained personnel. Strict safety protocols are essential to prevent accidents involving liquids near the furnace or improper handling of process gases.

Making the Right Choice for Your Goal

Selecting a melting technology depends entirely on the required quality of the final product and your operational goals.

- If your primary focus is producing state-of-the-art superalloys or medical-grade titanium: The VIM furnace is the industry standard, as purity and compositional control are non-negotiable.

- If your primary focus is high-volume manufacturing of standard-grade steels: A VIM furnace is likely overkill; a more cost-effective Electric Arc Furnace or a standard air-melt induction furnace would be more appropriate.

- If your primary focus is recycling high-value scrap metal into a purified, reusable form: A VIM furnace is an excellent choice, as it can effectively remove gaseous and volatile impurities during the remelting process.

Ultimately, choosing a VIM furnace is a decision to prioritize material quality and performance above all else.

Summary Table:

| Feature | Details |

|---|---|

| Maximum Temperature | Up to 2600°C (4712°F) |

| Key Benefits | High purity, precise control, homogeneity, degassing |

| Ideal Applications | Superalloys, refractory metals, medical-grade titanium, recycling |

| Limitations | High cost, batch processing, complex operation |

Ready to elevate your material quality with a custom VIM solution? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our VIM furnaces can deliver superior purity and performance for your specific needs!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control