Managing Samarium volatility requires a proactive compensation strategy. Because Samarium possesses a high saturated vapor pressure, it naturally tends to volatilize and escape during high-temperature vacuum melting processes, such as arc melting. To counteract this inevitable loss and ensure the final alloy matches the intended design, metallurgists intentionally add a specific excess amount of Samarium—typically around 2 wt.%—to the initial charge mixture.

The key to stable Sm-Co-Fe alloy production is "burn-off compensation." By factoring in the predictable loss of Samarium due to its high vapor pressure, manufacturers add a calculated excess of the element to ensure the final product meets strict compositional specifications.

The Physics of Volatilization

High Saturated Vapor Pressure

Samarium differs significantly from other transition metals in the alloy matrix, such as Cobalt or Iron.

Its defining characteristic in this context is a high saturated vapor pressure. This property makes the element chemically unstable when subjected to extreme heat under vacuum.

The Melting Environment

Vacuum melting is essential for purity, but it exacerbates the volatility of Samarium.

As the temperature rises to melt the Cobalt and Iron, the environment facilitates the evaporation of Samarium. Without intervention, this leads to a final product that is Samarium-deficient compared to the original calculation.

Implementing Burn-Off Compensation

The Principle of Excess Addition

To manage this volatility, engineers do not attempt to stop the evaporation; rather, they anticipate it.

This method is known as burn-off compensation. By adding more material than is theoretically required, the process accounts for the portion that will be lost to the vacuum chamber.

Specific Compensation Ratios

The primary reference indicates a standard baseline for this compensation.

A typical addition of 2 wt.% Samarium is added to the initial mixture. This specific proportion is calculated to offset the volatilization losses incurred during the arc melting process.

Targeting Design Composition

The ultimate goal of this excess addition is compositional accuracy.

The "extra" Samarium acts as a sacrificial buffer. Once the melting process is complete and the volatile portion has evaporated, the remaining Samarium content aligns perfectly with the intended alloy design.

Understanding the Trade-offs

Precision vs. Estimation

While adding 2 wt.% is a standard guideline, it is an estimation based on typical loss rates.

If the melting parameters change (e.g., longer melt times or different vacuum pressures), the loss rate may fluctuate. Relying solely on a fixed percentage without monitoring process variables can lead to slight compositional drift.

The Cost of Compensation

Samarium is a valuable rare earth element.

Intentionally allowing a portion of it to burn off represents a material cost. However, this cost is accepted as a necessary trade-off to ensure the structural and magnetic integrity of the final Sm-Co-Fe alloy.

Mastering Alloy Composition Control

Achieving the correct stoichiometry in Sm-Co-Fe alloys relies on balancing thermodynamics with practical inputs.

- If your primary focus is compositional accuracy: Adhere to the burn-off compensation method by adding approximately 2 wt.% excess Samarium to your initial charge.

- If your primary focus is process repeatability: Ensure your melting temperature and duration remain constant to keep the rate of volatilization consistent with your compensation calculations.

By anticipating the inevitable loss of volatile elements, you transform a chemical instability into a controllable manufacturing variable.

Summary Table:

| Factor | Description | Management Approach |

|---|---|---|

| Physical Challenge | High Saturated Vapor Pressure | Anticipate inevitable evaporation under vacuum |

| Material Loss | Volatilization of Samarium | Use "Burn-off Compensation" (Excess addition) |

| Standard Ratio | ~2 wt.% Samarium excess | Offset specific losses during arc melting |

| Process Goal | Stoichiometric Accuracy | Ensure final alloy matches target design |

| Key Variable | Melting Time & Pressure | Maintain constants for repeatable composition |

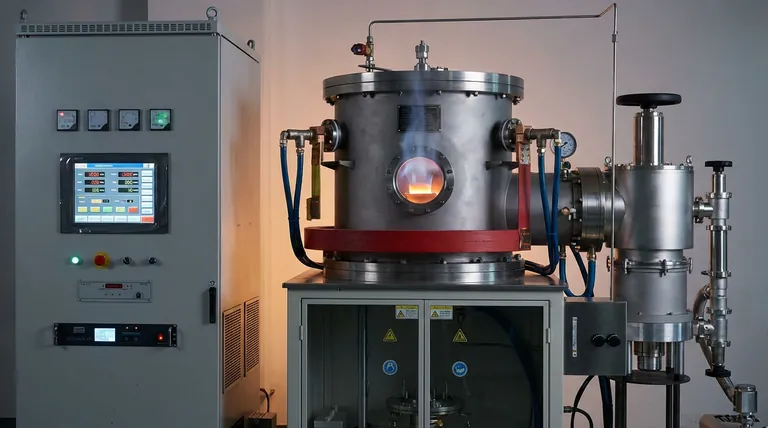

Optimize Your Sm-Co-Fe Alloy Production with KINTEK

Precision matters when handling volatile rare earth elements like Samarium. At KINTEK, we understand that high-performance alloys require more than just raw materials—they require controlled environments and expert engineering.

Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other specialized lab high-temp furnaces. All our systems are fully customizable to handle the specific thermodynamics of your unique projects, ensuring consistent heat and vacuum control to minimize unpredictable material loss.

Ready to achieve perfect stoichiometric results? Contact our experts today to find the ideal thermal solution for your lab or industrial manufacturing needs.

References

- Zhi Hong Zhu, Jiashuo Zhang. Effect of Fe Content on Phase Behavior of Sm–Co–Fe Alloys During Solidification and Aging. DOI: 10.3390/ma18081854

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Induction Melting Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Magnesium Extraction and Purification Condensing Tube Furnace

People Also Ask

- What role does vacuum induction melting play in the preparation of high-performance magnetic materials? Achieve Ultra-Pure Magnetic Alloys

- What is induction brazing and where is it used? Unlock Fast, Precise Metal Joining for Industry

- What is the role of frequency in melting PGM powders in an induction furnace? Essential for efficient heating and melting.

- Why is a Vacuum Induction Melting (VIM) furnace essential? Secure Superalloy Purity and Performance

- What is the primary use of induction furnaces in the manufacturing industry? Achieve Fast, Clean Metal Melting

- How do MgO crucibles affect melt purity? Strategies for High-Purity Vacuum Induction Remelting

- Why use vacuum arc furnaces and copper mold suction casting for Ti-xNb alloys? Key to Biomedical Material Excellence

- How does an induction furnace heat metal? Achieve Fast, Clean, and Precise Metal Melting