In essence, the primary use of an induction furnace in manufacturing is to melt metals with exceptional speed, efficiency, and precision. This technology is the cornerstone of modern foundries and metal processing facilities, particularly for producing high-quality steel, aluminum, copper, and precious metal alloys.

While many industrial processes can melt metal, the core problem is doing so cleanly, efficiently, and with the absolute control needed for modern materials. Induction furnaces solve this by using electromagnetic fields to heat the metal directly from within, making them an indispensable tool for high-quality manufacturing.

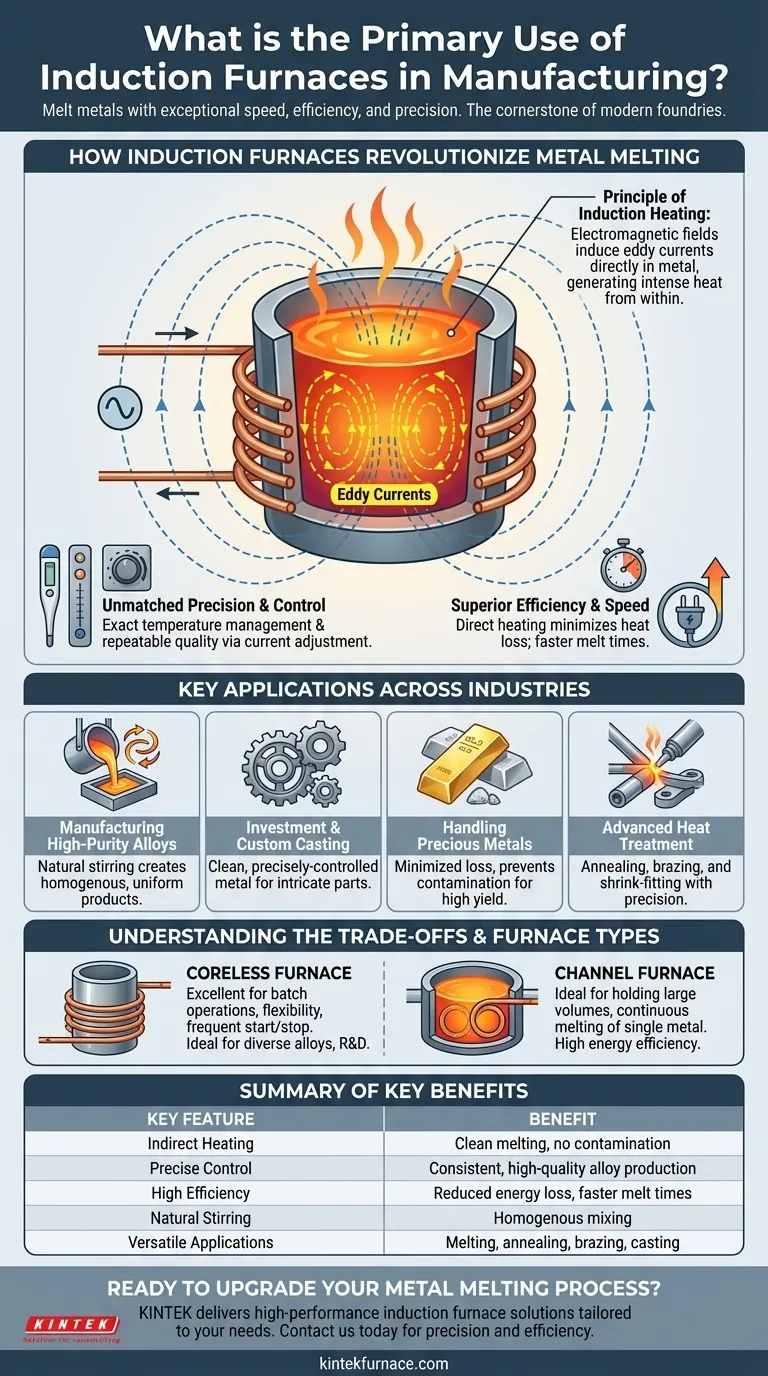

How Induction Furnaces Revolutionize Metal Melting

The value of an induction furnace lies not just in its ability to melt metal, but in how it achieves it. The process is fundamentally different from traditional fuel-fired or arc furnaces, offering distinct advantages.

The Principle of Induction Heating

An induction furnace operates without any external flame or heating element touching the metal. A powerful alternating current flows through a copper coil, generating a strong, fluctuating magnetic field around the crucible holding the metal charge.

This magnetic field induces powerful electrical currents, known as eddy currents, directly within the metal itself. The metal's natural electrical resistance causes these currents to generate intense heat, melting the material from the inside out.

Unmatched Precision and Control

Because the heat is generated by an electromagnetic field, operators have precise control over the melting process by adjusting the current's frequency and power.

This allows for exact temperature management, which is critical for meeting the tight specifications of modern alloys. The process is highly repeatable, ensuring consistent quality from one batch to the next.

Superior Efficiency and Speed

Heating the metal directly minimizes heat loss to the surrounding environment. This makes induction melting significantly more energy-efficient than methods that must first heat a chamber and then transfer that heat to the metal.

This direct heating is also incredibly fast, reducing overall melt times and increasing throughput.

Key Applications Across Industries

While "melting" is the primary function, its application is nuanced and critical across various high-value sectors. The controlled nature of induction heating makes it ideal for more than just turning solid metal into liquid.

Manufacturing High-Purity Alloys

The electromagnetic field creates a natural stirring action within the molten metal. This ensures all elements, including alloying agents, are distributed perfectly evenly, resulting in a homogenous and uniform final product.

Investment and Custom Casting

Induction furnaces are a mainstay in foundries for investment casting, copper casting, and aluminum casting. Their ability to produce clean, precisely-controlled molten metal is essential for creating intricate and high-quality cast parts.

Handling Precious Metals

For gold, platinum, and other precious metals, minimizing material loss and preventing contamination are paramount. The clean, contained nature of induction melting makes it the preferred method, ensuring the highest possible yield and purity.

Advanced Heat Treatment

The same principle of induction heating is used for other applications, such as annealing (softening metal to improve ductility), brazing (joining two pieces of metal), and shrink-fitting parts together with high precision.

Understanding the Trade-offs and Furnace Types

No technology is a universal solution. Understanding the different types of induction furnaces and their inherent limitations is key to making an informed decision.

Coreless vs. Channel Furnaces

The two main designs serve different operational needs.

Coreless induction furnaces consist of a simple crucible surrounded by the power coil. They are excellent for batch operations, melting a wide variety of metals and alloys, and for applications requiring frequent shutdowns and startups.

Channel induction furnaces function more like a transformer, with a loop of molten metal acting as the secondary coil. They are ideal for holding large volumes of molten metal at temperature and for the continuous melting of a single type of metal, offering very high energy efficiency in these scenarios.

Common Considerations

The primary trade-off is often the initial capital cost, which can be higher than some traditional furnace types. However, this is typically offset by lower operating costs due to higher energy efficiency, reduced material loss, and improved product quality.

Furthermore, while excellent for many applications, the largest-scale commodity steel production is still dominated by massive electric arc furnaces, which are designed for melting enormous quantities of scrap steel.

Making the Right Choice for Your Goal

Selecting the right melting technology depends entirely on your specific manufacturing objective.

- If your primary focus is high-value alloy production or investment casting: Induction is the superior choice for its precise temperature control and homogenous mixing capabilities.

- If your primary focus is large-scale, continuous melting of a single metal: A channel-type induction furnace offers the best energy efficiency for holding and melting large volumes.

- If your primary focus is rapid, clean melting of diverse batches (e.g., precious metals, R&D): A coreless induction furnace provides the necessary flexibility and minimizes the risk of cross-contamination.

Ultimately, the adoption of induction furnace technology is a strategic decision to prioritize quality, efficiency, and control in metal processing.

Summary Table:

| Key Feature | Benefit |

|---|---|

| Indirect Heating | Clean melting, no contamination, ideal for precious metals |

| Precise Control | Consistent, high-quality alloy production |

| High Efficiency | Reduced energy loss, faster melt times |

| Natural Stirring | Homogenous mixing for uniform final products |

| Versatile Applications | Melting, annealing, brazing, and custom casting |

Ready to upgrade your metal melting process with precision and efficiency?

At KINTEK, we leverage our advanced R&D and in-house manufacturing to deliver high-performance induction furnace solutions tailored to your unique needs. Whether you're producing high-purity alloys, handling precious metals, or require rapid batch melting, our expertise ensures you achieve superior results with unmatched control and energy savings.

Contact us today to discuss how our induction furnaces can transform your manufacturing operations!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How is operator safety ensured during the vacuum induction melting process? Discover Multi-Layered Protection for Your Lab

- What are the main applications of vacuum induction melting (VIM) furnaces? Achieve Unmatched Metal Purity for Critical Industries

- What components make up a Vacuum Induction Melting Furnace? Discover the Key Systems for Pure Metal Melting

- What industries benefit from Vacuum Induction Melting Furnaces? Unlock High-Purity Metals for Aerospace, Medical, and More

- What are the advantages of vacuum induction melting? Achieve Superior Purity for High-Performance Alloys