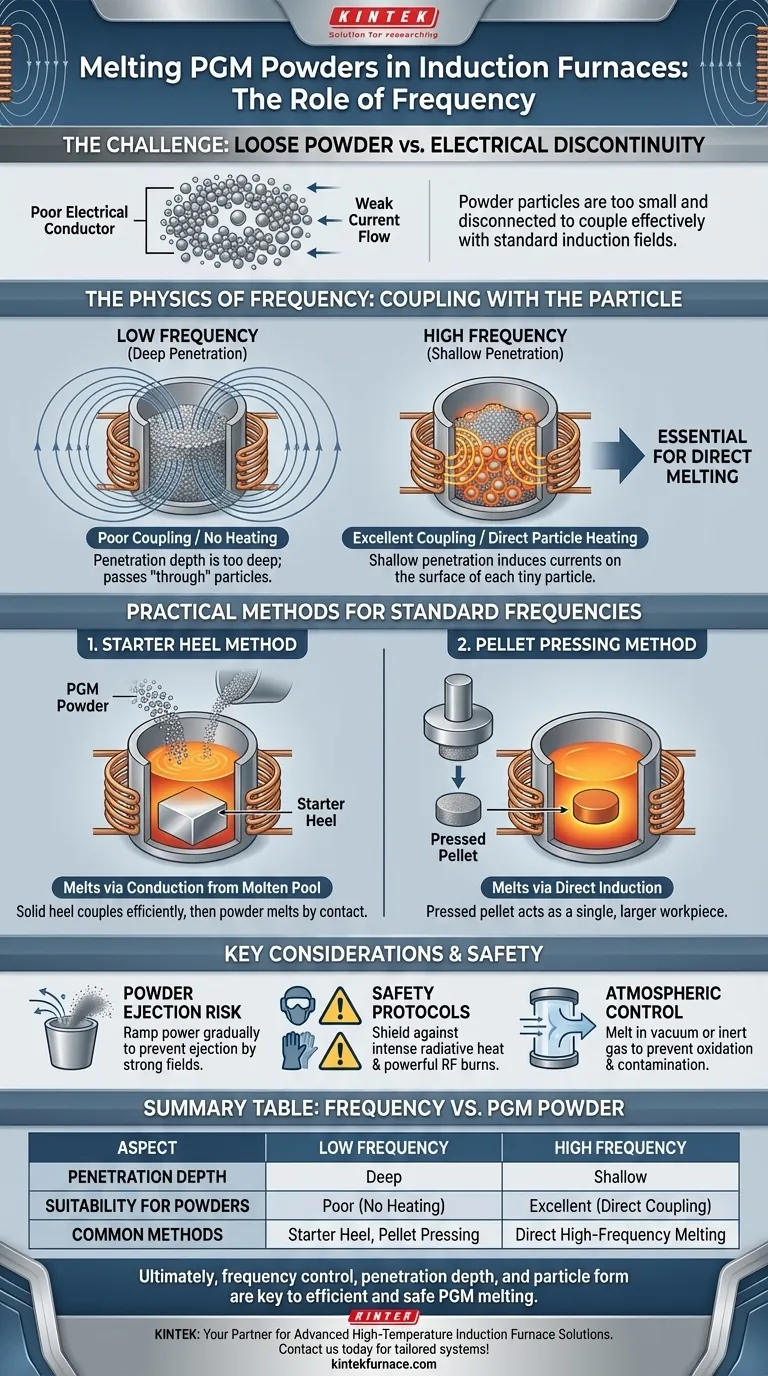

In short, a very high frequency is essential for melting Platinum Group Metal (PGM) powders in an induction furnace. This is because the individual powder particles are too small and electrically disconnected to couple effectively with the magnetic field generated at lower frequencies. The high-frequency field induces heating currents on the surface of each tiny particle, allowing the melting process to begin.

The core challenge with PGM powders is their physical form, not their metallic properties. Loose powder acts as a poor electrical conductor, resisting induction heating. The solution is either to use a very high frequency to couple with the tiny particles directly or to use a solid "starter heel" to bypass this initial coupling problem entirely.

Why PGM Powders Present a Unique Challenge

The difficulty in melting PGM powders stems from the fundamental physics of induction. The process relies on creating a strong electrical current within the material, but a pile of powder poses a significant obstacle.

The Problem of Electrical Discontinuity

An induction furnace works by generating a powerful, alternating magnetic field. This field must induce circular electrical currents, known as eddy currents, within the metal charge.

In a solid piece of metal, these currents flow easily, generating immense heat through electrical resistance. However, a powder is a collection of individual particles with air gaps and oxide layers between them, creating extremely poor electrical continuity. The magnetic field cannot establish a strong, unified current through the entire mass.

The Physics of Frequency and Penetration Depth

The frequency of the alternating magnetic field is the most critical parameter. It directly controls how deeply the eddy currents penetrate into the surface of the material.

The relationship is simple:

- Low Frequency: Creates deep-penetrating eddy currents, ideal for large, solid workpieces.

- High Frequency: Creates shallow, surface-hugging eddy currents, ideal for small workpieces.

Think of it like sound waves. A low-frequency bass note can travel through walls, while a high-frequency hiss is easily blocked. Similarly, a low-frequency magnetic field passes "through" tiny powder particles without effectively coupling, whereas a high-frequency field concentrates its energy权利 on their small surfaces.

Matching the Frequency to the Particle

To heat efficiently, the penetration depth of the eddy currents should be a fraction of the workpiece's diameter (a common rule of thumb is no more than 1/8th).

For a mass of PGM powder, the "workpiece" is each individual grain. Therefore, a very high frequency is required to create a sufficiently shallow penetration depth that can effectively induce heat in each tiny particle.

Practical Methods for Melting PGM Powder

Because specialized, very-high-frequency furnaces are not always available, metallurgists have developed reliable workarounds to solve the coupling problem.

The Starter Heel Method

The most common industrial practice is to use a starter heel. This is a solid piece of a compatible metal placed in the bottom of the crucible.

The solid heel, being a large, contiguous workpiece, couples eficiência with a lower, standard frequency. It heats up and melts, creating a molten pool. The PGM powder is then added slowly to this molten bath, where it melts价格 by simple conduction rather than by direct induction.

The Pellet Pressing Method

For smaller or experimental batches, an effective alternative is to press the PGM powder into a solid pellet or briquette.

By compacting the powder, you create a single, larger workpiece. This new form has better electrical continuity and a larger diameter, allowing it to couple more effectively with the magnetic field at a frequency that might be too low for the loose powder.

Common Pitfalls and Key Considerations

Successfully melting PGM powders requires careful control to ensure efficiency and safety.

The Risk of Powder Ejection

A primary risk is blowing the fine powder out of the crucible. The strong, alternating magnetic field can exert a physical force on the particles.

To prevent this, you must ramp up the power gradually. Start low and slowly increase power as the material begins to consolidate and melt, whether you are using a starter heel or a pressed pellet.

Choosing the Right Approach

Using a frequency that is too low for loose powder will result in no heating at all. The process will simply fail. The starter heel and pellet methods are designed specifically to accommodate the capabilities of more common, lower-frequency induction systems.

Critical Safety Protocols

Working with molten PGMs in an induction furnace carries significant risk.

- Radiative Heat: Always wear aluminized protective gear to shield against intense infrared radiation.

- RF Burns: The high-frequency coils generate a powerful radiofrequency field. Ensure coils are properly shielded to prevent severe RF burns from accidental contact or proximity.

- Atmospheric Control: PGMs are often melted in a vacuum or under an inert gas (like argon) to prevent contamination and oxidation, which can be explosive or ruin the purity of the melt.

Making the Right Choice for Your Goal

Your melting strategy should be dictated by your equipment, batch size, and production demands.

- If your primary focus is melting small, experimental batches: Pressing the powder into a pellet is often the most direct and efficient method.

- If your primary focus is running larger, production-scale melts: The starter heel method is the reliable, standard industrial practice for its predictability and scalability.

- If your furnace has variable-frequency control: You can start with a very high frequency to couple directly with the powder, then potentially lower it once a molten pool is formed to optimize stirring and heating in the liquid bath.

Ultimately, understanding the relationship between frequency, penetration depth, and particle size empowers you to control your melting process.

Summary Table:

| Aspect | Low Frequency | High Frequency |

|---|---|---|

| Penetration Depth | Deep | Shallow |

| Suitability for PGM Powders | Poor (no heating) | Excellent (direct particle coupling) |

| Common Methods | Starter heel, pellet pressing | Direct high-frequency melting |

Need advanced high-temperature furnace solutions for your PGM melting challenges? KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with tailored induction furnace systems. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how we can enhance your melting efficiency and safety!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors