In modern industrial heating, medium frequency induction furnaces provide a distinct advantage through exceptional speed, precise control, and high energy efficiency. By using electromagnetic induction to generate heat directly within the material itself, these systems bypass the inefficiencies and limitations of conventional fuel-fired or resistance furnaces, leading to cleaner operations and a higher quality final product.

The core benefit of a medium frequency induction furnace is not just that it melts metal, but how it does so. It offers direct, contactless, and precisely controllable heating, which translates into faster production cycles, superior material consistency, and a significant reduction in energy waste compared to traditional methods.

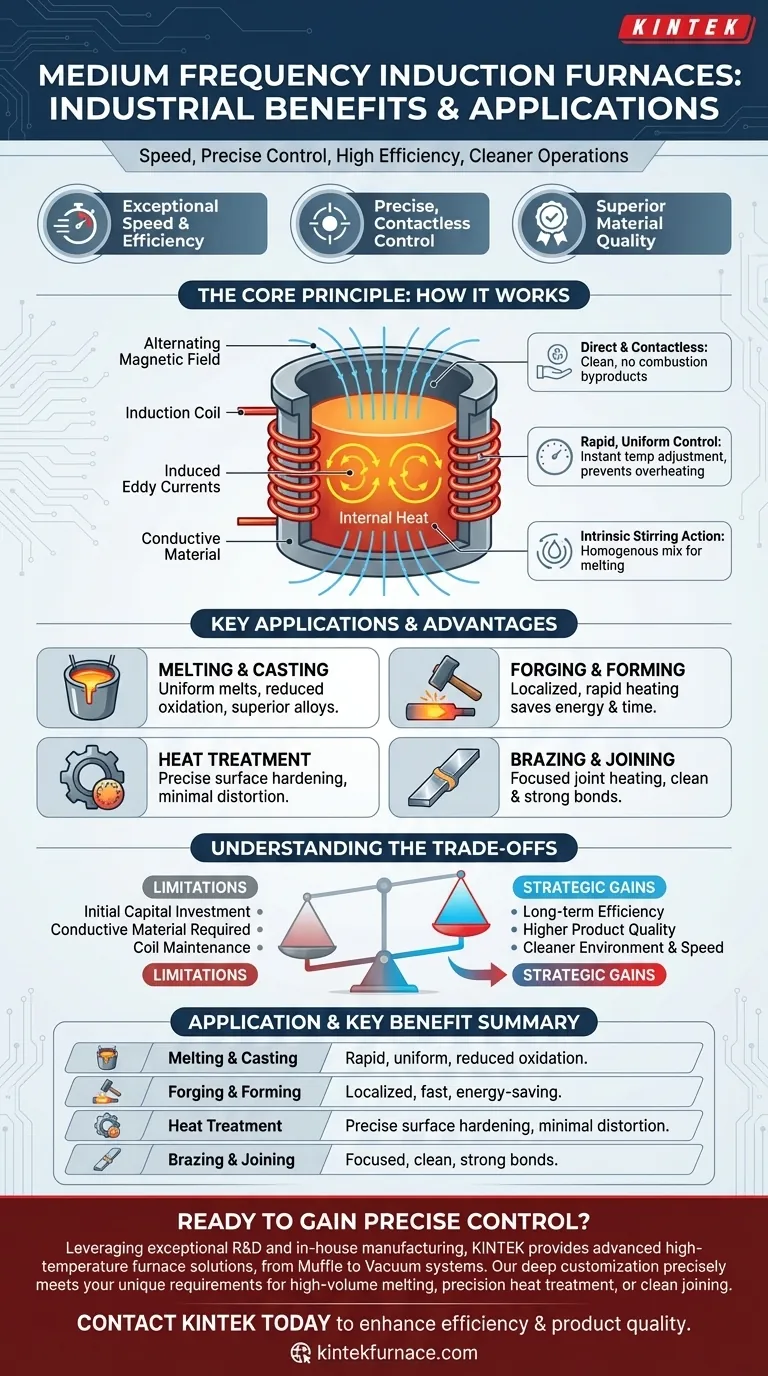

The Core Principle: How Induction Delivers Superior Performance

To understand the benefits, you must first understand the mechanism. Unlike a conventional furnace that heats the outside of a material with flames or glowing elements, an induction furnace uses a powerful, alternating magnetic field.

Direct and Contactless Heating

This magnetic field induces electrical eddy currents directly inside the conductive workpiece. The material's own electrical resistance causes these currents to generate intense, rapid heat from within.

This process is entirely contactless, eliminating contamination from combustion byproducts and reducing the need for crucibles in some applications, ensuring material purity.

Rapid and Uniform Temperature Control

Because the heat is generated inside the material, heating is extremely fast. The power supplied to the induction coil can be adjusted instantly, allowing for incredibly precise control over the material's temperature and the rate of heating.

This level of control is critical for achieving specific metallurgical properties and preventing overheating or material degradation.

Intrinsic Stirring Action

A unique advantage in melting applications is the electromagnetic stirring effect. The same forces that generate heat also create a natural, vigorous stirring motion within the molten metal.

This ensures a homogenous mix of alloys and a uniform temperature throughout the melt, leading to consistently high-quality castings without mechanical stirrers.

Key Applications and Their Advantages

The versatility of medium frequency induction furnaces stems from their ability to be tailored to specific industrial tasks, each benefiting from the core principles of induction heating.

Melting and Casting

This is a primary application. Foundries use these furnaces to melt iron, steel, copper, and aluminum alloys. The precise temperature control and stirring action result in superior, uniform melts and reduce the loss of valuable alloying elements through oxidation.

Forging and Forming

For forging, only the portion of the metal to be worked needs to be heated. Induction allows for the rapid, localized heating of billets or the ends of steel pipes, saving significant energy and time compared to heating the entire workpiece in a large furnace.

Heat Treatment and Surface Hardening

Processes like quenching and tempering demand exact temperature control. Induction can heat the surface of a part (like a gear or shaft) to a precise depth and temperature before it's quenched, creating a hardened surface layer while leaving the core ductile.

Brazing and Joining

When joining metal components, induction heating can be focused precisely on the joint area. This melts the brazing filler material to create a strong, clean bond without heating and potentially distorting the entire assembly, a common issue in electronics and precision manufacturing.

Understanding the Trade-offs

While highly effective, induction technology is not a universal solution. An objective evaluation requires acknowledging its limitations.

Initial Capital Investment

The technology powering an induction furnace—including the power supply, water-cooling system, and custom coils—represents a higher upfront cost compared to simpler, conventional furnaces. This investment must be weighed against long-term gains in efficiency and product quality.

Material Constraints

The fundamental principle of induction heating requires the workpiece to be electrically conductive. It is not suitable for heating non-conductive materials like ceramics or certain polymers directly.

Coil Design and Maintenance

The induction coil is the heart of the system and must be properly designed for the specific size and shape of the workpiece to be efficient. These water-cooled copper coils are durable but are a critical maintenance point and can be damaged by contact with the workpiece or overheating.

Making the Right Choice for Your Operation

Selecting the right heating technology depends entirely on your primary operational goal.

- If your primary focus is high-volume metal melting: The key benefit is the combination of rapid melt cycles, superior alloy homogeneity from electromagnetic stirring, and higher energy efficiency.

- If your primary focus is precision heat treatment or joining: The key benefit is the unparalleled control over the heat zone's location and temperature, which minimizes part distortion and improves finished quality.

- If your primary focus is operational efficiency and a cleaner work environment: The key benefit is the elimination of combustion fumes, reduced ambient heat, and faster cycle times that increase overall throughput.

Ultimately, adopting a medium frequency induction furnace is a strategic decision to gain precise control over your heating processes, resulting in a more efficient and capable operation.

Summary Table:

| Application | Key Benefit |

|---|---|

| Melting & Casting | Rapid melting, electromagnetic stirring for uniform alloys, reduced oxidation |

| Forging & Forming | Localized, rapid heating saves energy and time compared to whole-workpiece heating |

| Heat Treatment | Precise surface hardening and tempering with minimal part distortion |

| Brazing & Joining | Focused heating on joint area for clean, strong bonds without assembly distortion |

Ready to gain precise control over your industrial heating processes?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories and production facilities with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique application requirements—whether for high-volume melting, precision heat treatment, or clean joining operations.

Contact KINTEL today to discuss how our induction heating solutions can enhance your efficiency, product quality, and operational capability.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- How does the use of vacuum in hot-pressing affect the material processing? Achieve Denser, Purer, and Stronger Materials

- What are the advantages of ceramic/metal composites produced using a vacuum press? Achieve Superior Strength and Durability

- What is the process of vacuum hot pressing? Achieve Ultra-Dense, High-Purity Materials

- How does induction heating ensure precision in manufacturing processes? Achieve Superior Thermal Control & Repeatability

- What are the main applications of vacuum hot pressing? Create Dense, Pure Materials for Demanding Industries