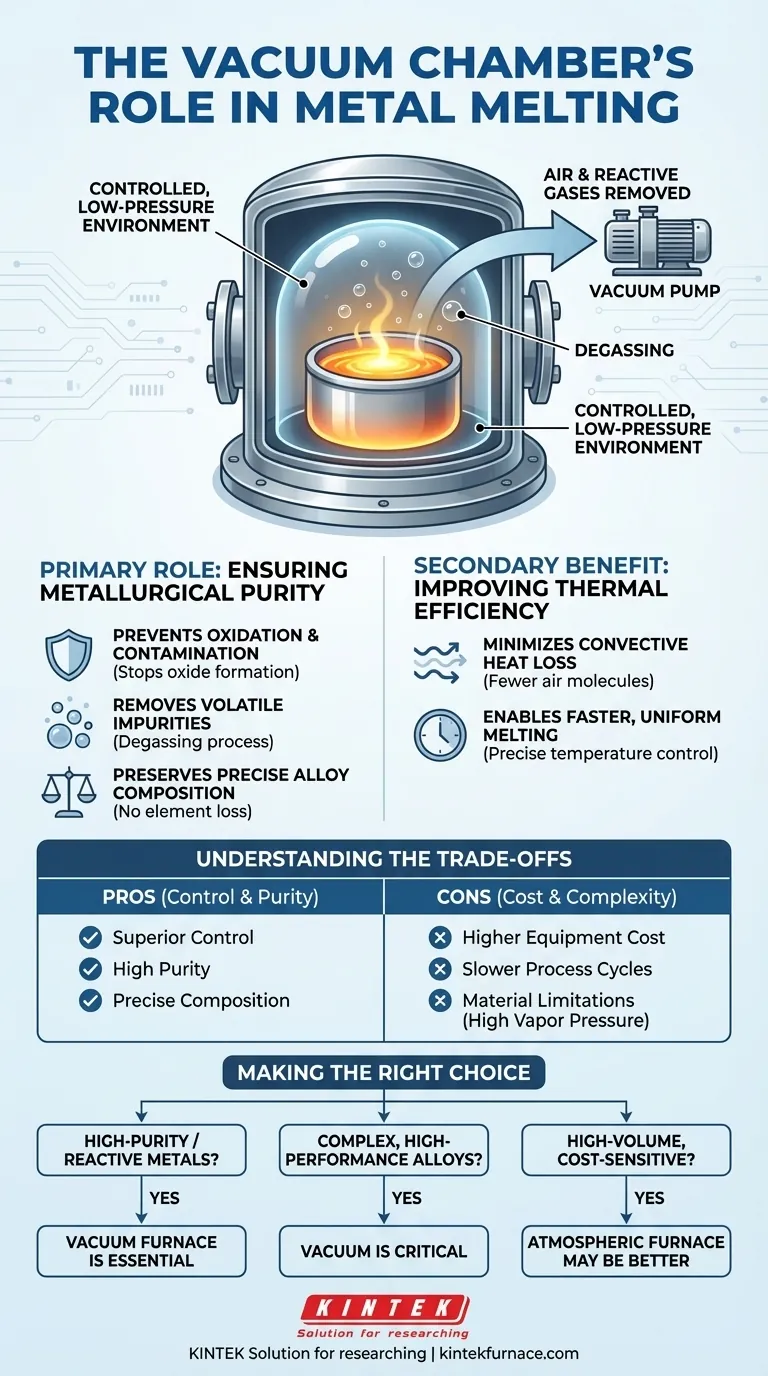

At its core, the vacuum chamber’s role in the melting process is to create a low-pressure, controlled environment by removing air and other reactive gases. This fundamental action prevents the molten metal from reacting with the atmosphere, which drastically reduces oxidation and contamination, thereby improving the purity, composition, and overall quality of the final metal.

The vacuum chamber is not merely a container; it is an active system that transforms the melting process from an uncontrolled atmospheric reaction into a precisely managed metallurgical operation. This control is the key to producing high-purity metals and complex alloys that would be impossible to create in open air.

The Primary Role: Ensuring Metallurgical Purity

When metal is melted in the open air, it is immediately exposed to a host of elements that can degrade its quality. The vacuum chamber's primary function is to eliminate this atmospheric interference.

Preventing Oxidation and Contamination

Molten metal is highly reactive with oxygen. This reaction, known as oxidation, forms impurities (oxides) that can become trapped in the final product, creating defects and weakening the material.

By removing the air, the vacuum chamber starves the reaction of its key ingredient: oxygen. This prevents the formation of oxides and other compounds, resulting in a cleaner, higher-purity metal.

Removing Volatile Impurities

The low-pressure environment created by the vacuum chamber does more than just prevent contamination from entering the melt—it actively helps pull impurities out.

Gases and other volatile elements dissolved within the raw metal will "boil off" under vacuum. This process, known as degassing, is critical for removing unwanted elements and further refining the metal.

Preserving Precise Alloy Composition

Many advanced materials, like superalloys, rely on a precise chemical balance of multiple elements. Some of these alloying elements can be lost or "burned off" when melted in air.

The vacuum environment prevents these undesirable side reactions, ensuring that the final composition of the alloy is exactly what was designed. This control is essential for applications in aerospace and medical industries where material consistency is non-negotiable.

The Secondary Benefit: Improving Thermal Efficiency

Beyond purity, the vacuum chamber fundamentally changes the physics of the heating process itself, leading to significant efficiency gains.

Minimizing Convective Heat Loss

In a normal atmosphere, a significant amount of heat energy is lost as it transfers to the surrounding air molecules through convection. This is a major source of inefficiency.

Because a vacuum is largely empty space, there are far fewer air molecules to carry heat away from the melt. This drastically reduces convective heat loss, allowing more of the applied energy to go directly into melting the metal.

Enabling Faster, More Uniform Melting

With less heat escaping, the melting process becomes more efficient and uniform. The charge can reach its melting point faster, and temperature can be controlled more precisely throughout the molten pool. This is a key advantage in processes like Vacuum Arc Melting (VAM) and Vacuum Induction Melting (VIM).

Understanding the Trade-offs

While vacuum melting offers superior control and purity, it is not without its challenges. Understanding these trade-offs is crucial for making an informed decision.

Higher Equipment Cost and Complexity

Vacuum furnaces, with their robust chambers, seals, and powerful pumping systems, are significantly more complex and expensive than their atmospheric counterparts. The operational knowledge required is also more specialized.

Slower Process Cycles

Achieving a deep vacuum is not instantaneous. The "pump-down" time required to evacuate the chamber before melting can begin adds to the overall cycle time for each batch, potentially reducing throughput compared to simpler methods.

Material Limitations

Not all metals are suitable for vacuum melting. Elements with a very high vapor pressure can be unintentionally vaporized and drawn out by the vacuum system, altering the alloy's final composition.

Making the Right Choice for Your Goal

The decision to use a vacuum chamber depends entirely on the material requirements and project goals.

- If your primary focus is high-purity or reactive metals (like titanium): A vacuum furnace is non-negotiable, as it is the only way to prevent catastrophic contamination.

- If your primary focus is complex, high-performance alloys: A vacuum is essential for maintaining the precise chemical composition required for these materials to perform.

- If your primary focus is high-volume, cost-sensitive production of standard metals: A traditional atmospheric furnace is likely the more economical and efficient choice.

Ultimately, employing a vacuum chamber is a deliberate choice to prioritize material purity and compositional control above all else.

Summary Table:

| Role Aspect | Key Benefit |

|---|---|

| Metallurgical Purity | Prevents oxidation and contamination, removes volatile impurities via degassing |

| Alloy Composition | Preserves precise chemical balance for superalloys and reactive metals |

| Thermal Efficiency | Reduces convective heat loss, enables faster and more uniform melting |

| Trade-offs | Higher cost and complexity, slower process cycles, material limitations |

Ready to elevate your metal melting with superior purity and efficiency? KINTEK specializes in advanced high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces, tailored for diverse laboratories. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs for reactive metals and complex alloys. Contact us today to discuss how our expertise can enhance your process!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity