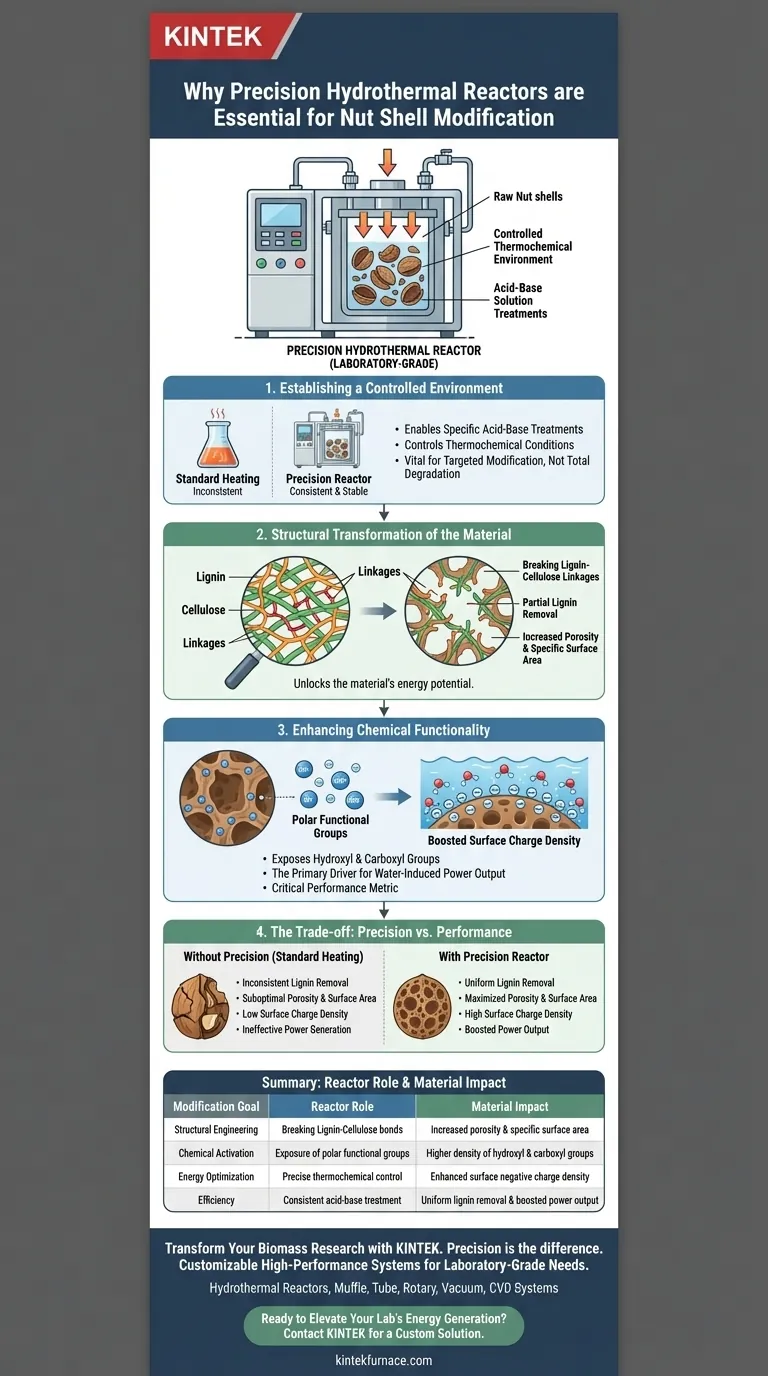

Precision hydrothermal reactors are essential because they create the strictly controlled thermochemical environment required to effectively modify nut shell materials using acid-base solutions. These laboratory-grade devices facilitate the partial removal of lignin and the breaking of internal bonds between lignin and cellulose, a process that is critical for activating the material's energy-generating potential.

By enabling precise structural and chemical modifications, these reactors significantly increase the material's surface charge density, which is the primary driver for boosting water-induced power output.

Establishing a Controlled Environment

Enabling Specific Acid-Base Treatments

The primary role of a precision hydrothermal reactor is to facilitate specific acid-base solution treatments.

Standard heating methods often lack the stability required for these chemical reactions. A laboratory-grade device ensures the environment remains consistent throughout the treatment process.

Controlling Thermochemical Conditions

The modification of nut shells is a thermochemical process.

Precision reactors maintain the exact thermal and chemical conditions needed to alter the biomass without destroying it completely. This balance is vital for targeted modification rather than total degradation.

Structural Transformation of the Material

Breaking Lignin-Cellulose Linkages

The reactor environment is designed to break the internal linkages between lignin and cellulose.

This structural disruption is necessary to "unlock" the material. It allows for the partial removal of lignin, which is a key step in processing the raw nut shells.

Increasing Porosity and Surface Area

As linkages break and lignin is removed, the physical architecture of the material changes.

This process significantly increases the specific surface area and the porosity of the nut shells. A more porous structure provides a greater surface area for interaction with water.

Enhancing Chemical Functionality

Exposing Polar Functional Groups

The ultimate goal of the structural changes is to alter surface chemistry.

The treatment exposes more polar functional groups, specifically hydroxyl and carboxyl groups. These groups are typically locked away in the raw biomass but are made accessible through this precision treatment.

Boosting Surface Charge Density

The exposure of polar groups leads to a significant enhancement in surface negative charge density.

This is the critical performance metric. A higher negative charge density directly correlates to boosted water-induced power output, making the material an effective energy generator.

The Trade-off: Precision vs. Performance

The Cost of Inconsistency

While precision reactors add complexity to the process, attempting this modification without them typically leads to inconsistent lignin removal.

If the internal linkages are not broken uniformly, the material will fail to develop the necessary porosity.

The Impact on Power Generation

Without the controlled environment, the exposure of hydroxyl and carboxyl groups will be suboptimal.

This results in low surface charge density. Consequently, the material will not achieve the desired boost in power output, rendering the modification effort ineffective.

Optimizing Material Performance

To ensure you achieve the desired results from your nut shell modification, apply the following principles:

- If your primary focus is Structural Engineering: Use precision reactors to maximize specific surface area and porosity by effectively breaking lignin-cellulose bonds.

- If your primary focus is Energy Generation: Prioritize the controlled exposure of hydroxyl and carboxyl groups to maximize surface negative charge density.

The precision hydrothermal reactor is not just a heating vessel; it is the fundamental tool required to convert raw biomass into a high-performance functional material.

Summary Table:

| Modification Goal | Reactor Role | Material Impact |

|---|---|---|

| Structural Engineering | Breaking Lignin-Cellulose bonds | Increased porosity and specific surface area |

| Chemical Activation | Exposure of polar functional groups | Higher density of hydroxyl and carboxyl groups |

| Energy Optimization | Precise thermochemical control | Enhanced surface negative charge density |

| Efficiency | Consistent acid-base treatment | Uniform lignin removal and boosted power output |

Transform Your Biomass Research with KINTEK

Precision is the difference between raw biomass and high-performance functional materials. Backed by expert R&D and manufacturing, KINTEK offers high-performance Hydrothermal Reactors, Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to your specific chemical modification needs. Whether you are optimizing lignin removal or boosting surface charge density, our laboratory-grade devices provide the stability your research demands.

Ready to elevate your lab’s energy generation capabilities? Contact KINTEK today for a custom solution!

Visual Guide

References

- Nazmul Hossain, Y. Zhou. Hydrovoltaic Energy Harvesting From Nut Shells. DOI: 10.1002/eem2.70017

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- Why is 5G network infrastructure critical for real-time quality control? Achieve Zero-Defect Thermal Processing

- What are the main types of sintering methods for metals, ceramics, and refractory intermetallic compounds powders? Optimize Your Material Processing

- Why is MgO used as a hard template for waste PET to carbon conversion? Unlock 3D Porous Structures

- How do elliptical mirrors function to create a horizontal temperature field in an optical Floating-Zone furnace?

- How do vertical reaction furnaces simulate blast furnace reduction? Recover Iron from Steel Waste Effectively

- What are some examples of medium-temperature industrial heating processes? Optimize Material Properties Efficiently

- What is the purpose of using a liquid nitrogen adsorption instrument and BET analysis? Characterize RCM Nanosheets

- Why is a laboratory vacuum oven utilized for ZnO-FL drying? Preserving Delicate Nanoparticle Morphologies